Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

MPM4780

Used For

Pressure and Temperature Measurement

Leave a MessageMPM4780 intelligent pressure transmitter is an intelligent measurement instrument with an integrated structure design and standard digital signal output. It is designed for applications that require the ModBus-RTU protocol. MPM4780 adopts advanced pressure transmitter design and manufacturing technology. The measuring range covers a wide range, and the measurable range is -1bar...0~0.1bar...1000bar. MPM4780 pressure transducer is suitable for precise measurement of fluid pressure in various industries.

Features

• RS485 output signal

• Compact size, light weight

Specification

• Range: -1bar…0bar~0.1bar…1000bar

• Pressure type: Gauge/ Absolute/ Sealed gauge

• Power Supply: 9V~28V DC

• Output signal: RS485 Interface(MODBUS-RTU protocol)

• Accuracy: ±0.5%FS

• Thermal drift: ±0.04%FS/℃ (≤1bar); ±0.03%FS/℃ (>1bar)

• Measurement Error: ±2℃ (For “temperature & pressure type” only)

• Application Temp.: -30℃ ~ 80℃ ; -10℃ ~ 70℃ (cable)

• Stability: ±0.3%FS/YEAR

• Shock: 20g, 25Hz~2000Hz

Image:

MPM4780 intelligent pressure transmitter is an intelligent measurement instrument with an integrated structure design and standard digital signal output. It is designed for applications that require the ModBus-RTU protocol. MPM4780 adopts advanced pressure transmitter design and manufacturing technology. The measuring range covers a wide range, and the measurable range is -1bar...0~0.1bar...1000bar. MPM4780 pressure transducer is suitable for precise measurement of fluid pressure in various industries.

Features

• RS485 output signal

• Compact size, light weight

Specification

• Range: -1bar…0bar~0.1bar…1000bar

• Pressure type: Gauge/ Absolute/ Sealed gauge

• Power Supply: 9V~28V DC

• Output signal: RS485 Interface(MODBUS-RTU protocol)

• Accuracy: ±0.5%FS

• Thermal drift: ±0.04%FS/℃ (≤1bar); ±0.03%FS/℃ (>1bar)

• Measurement Error: ±2℃ (For “temperature & pressure type” only)

• Application Temp.: -30℃ ~ 80℃ ; -10℃ ~ 70℃ (cable)

• Stability: ±0.3%FS/YEAR

• Shock: 20g, 25Hz~2000Hz

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100bar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.15%FS (Typ.)

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

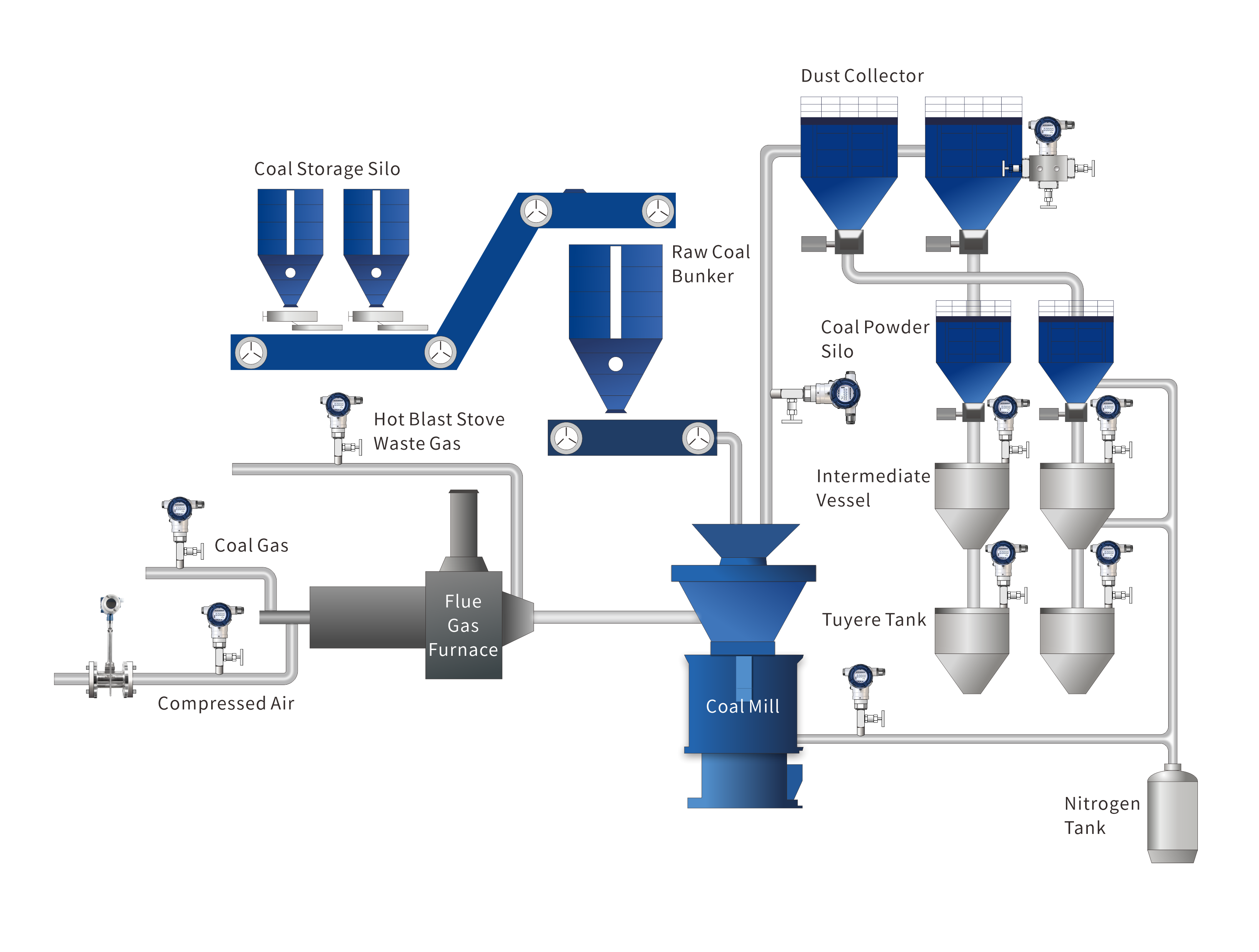

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the metallurgy industry to ensure smelting process efficiency and product quality. In the demanding high-temperature, high-pressure, and harsh environments of the metallurgy industry, Micro Sensor comprehensive monitoring solutions provide real-time data acquisition and precise regulation by integrating smart control systems and advanced sensor technologies. These systems optimize metal production processes for safe and effective operations.

more info...

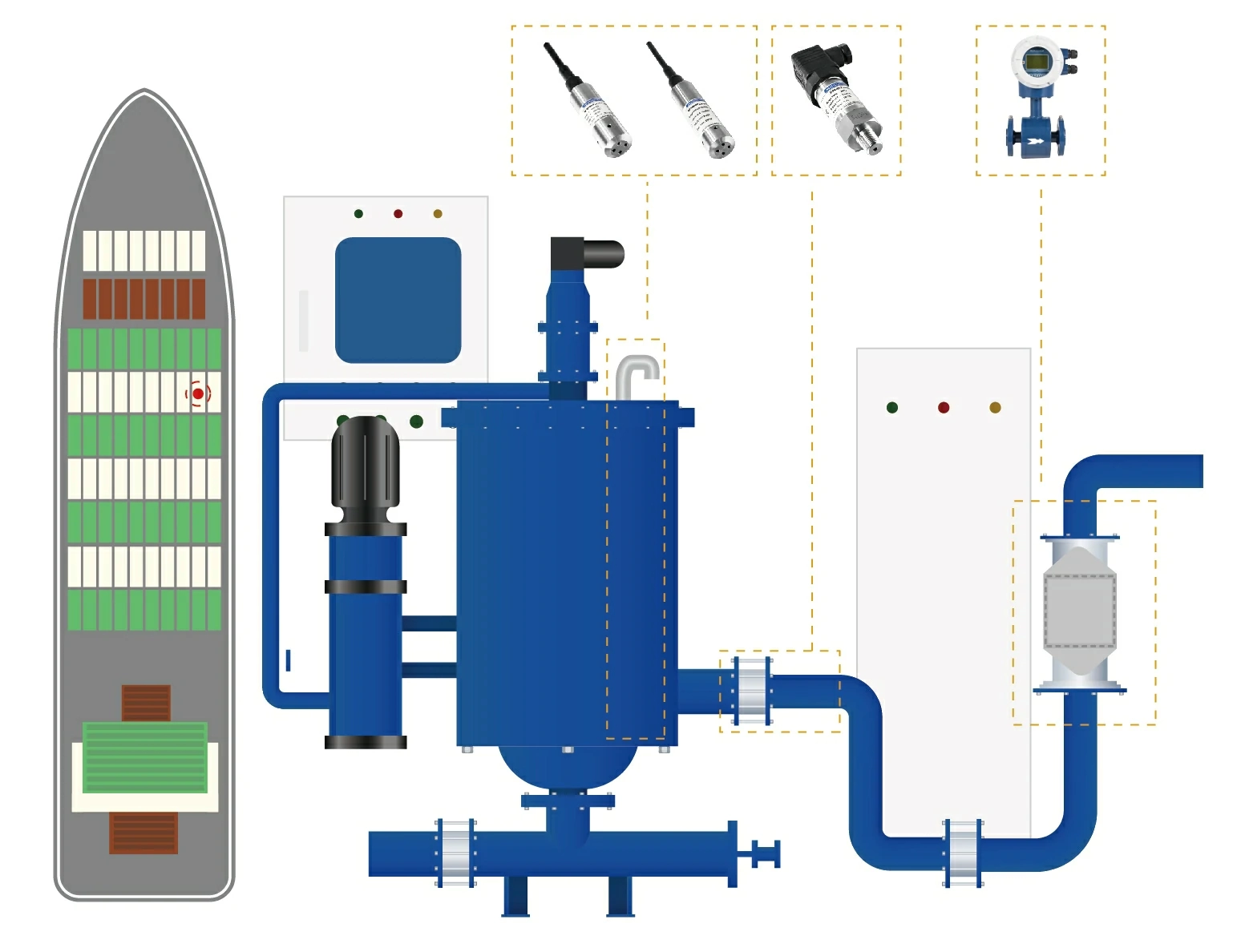

Ballast tank level monitoring achieves precise control of the ballast water system by using equipment such as electromagnetic flowmeters, level transmitters, and pressure transmitters to monitor data on inflow, tank liquid level, and pressure.

more info...

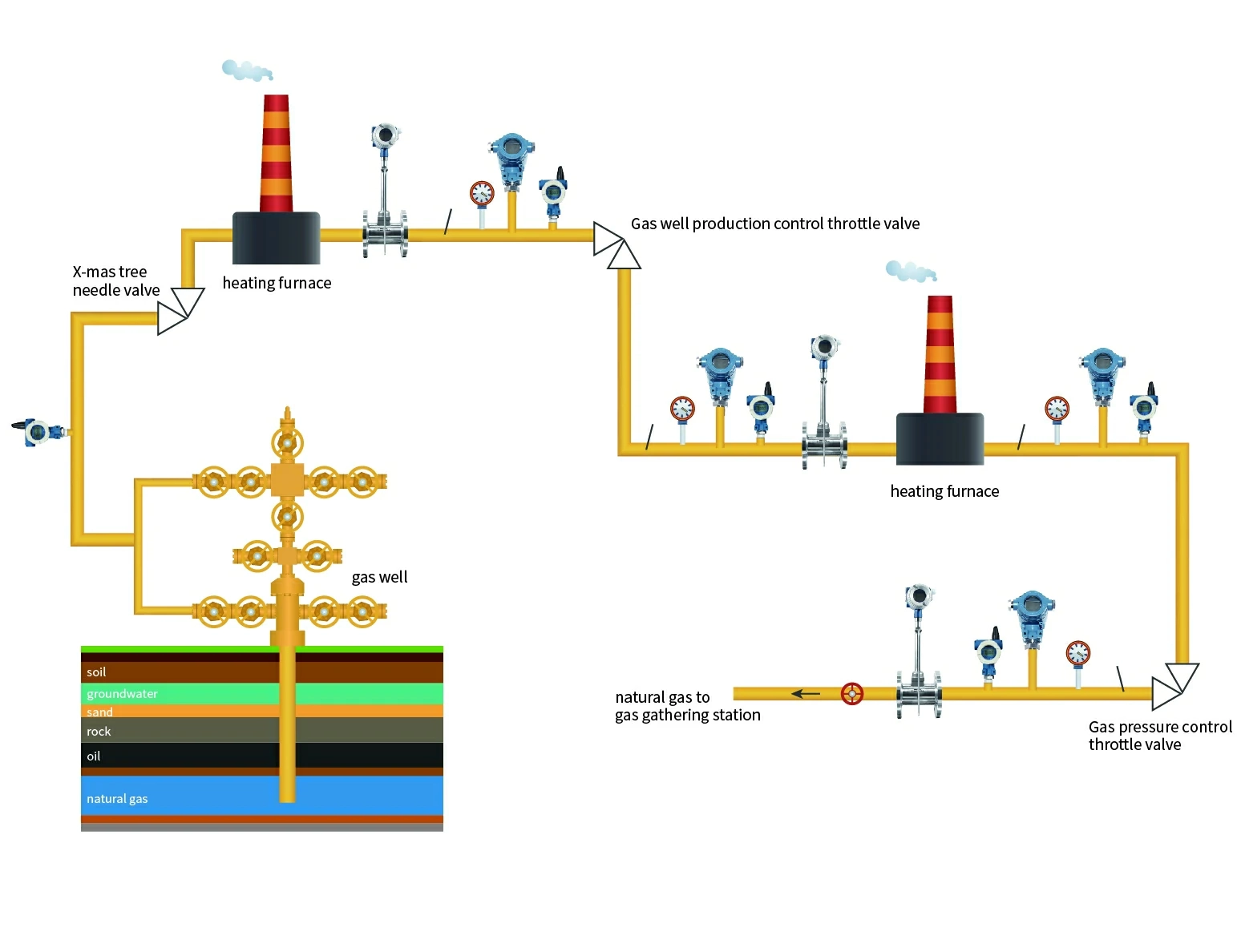

Centralizing the oil and gas produced by scattered oil wells, processing and initial processing, and exporting it after meeting the standards. The process requires multiple steps, including oil and gas separation, crude oil dehydration, and natural gas purification, thus requiring various instruments to measure production parameters.

more info...

Perfect coffee needs pressure. Water and steam pressure monitoring of the coffee machine ensures safe and high-quality coffee production. Accurately measuring pressure is required during the coffee bean extraction, hot water delivery, and cleaning of coffee machines.

more info...