Piezoresistive Pressure Sensor

Φ19×11.5mm

0bar~0.35bar…1000bar

0~70℃ Compensated

MPM4881

Used For

Automatic Pressure Detection, Motion Control and Water Level Alarm of Equipment

Leave a MessageMPM4881 Pressure Transmitting Controller is used in remote pressure measurement and control. MPM4881 shows high adaptability when high-frequency or high switching precision is required and mechanical pressure relays are not capable. MPM4881 has a terminal protection cover or a waterproof connector to prevent dust and short circuits. Button operation is simpler and more convenient.

Features

• The panel supports 180° rotation

• Accurate measurement, fast response and control of multiple relays

• Hardware misuse protection

• IP65 protection level of the whole machine

• Various mounting of back mounting, rail mounting, cover mounting and joint

Specification

• Measurement Range: 0bar~0.1bar...600bar

• Overpressure: 1.5 FS

• Output Accuracy: ≤±0.25%FS; ≤±0.5%FS

• Output Mode: 5 relays, normally open or closed contact

• Display: 4 digit 0.56 inch 14-segment LED display

Image:

MPM4881 Pressure Transmitting Controller is used in remote pressure measurement and control. MPM4881 shows high adaptability when high-frequency or high switching precision is required and mechanical pressure relays are not capable. MPM4881 has a terminal protection cover or a waterproof connector to prevent dust and short circuits. Button operation is simpler and more convenient.

Features

• The panel supports 180° rotation

• Accurate measurement, fast response and control of multiple relays

• Hardware misuse protection

• IP65 protection level of the whole machine

• Various mounting of back mounting, rail mounting, cover mounting and joint

Specification

• Measurement Range: 0bar~0.1bar...600bar

• Overpressure: 1.5 FS

• Output Accuracy: ≤±0.25%FS; ≤±0.5%FS

• Output Mode: 5 relays, normally open or closed contact

• Display: 4 digit 0.56 inch 14-segment LED display

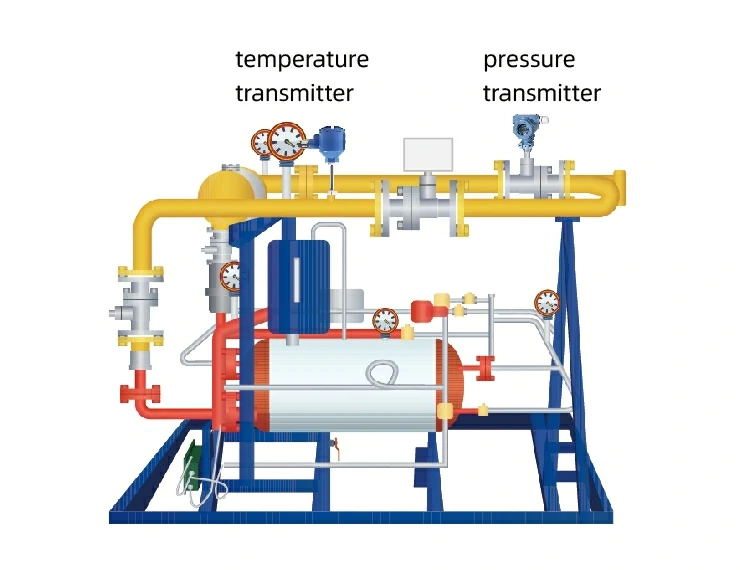

Gas skid equipment is a critical component in gas distribution systems. Equipped pressure and temperature transmitters can monitor parameters in real time. Then, the data is transmitted remotely to a central control room. The engineer or operator detects abnormal situations in time. It ensures the normal operation of the equipment and system.

more info...

In an inkjet printer, the continuous inkjet state of the ink nozzles ensures print quality. Normal ejection of ink in the nozzle requires continuous application of pressure. The pressure detection component monitors and controls the pressure. High-precision, high-sensitivity pressure sensors control the accurate delivery of ink during printing.

more info...

High-speed paper mills use a vacuum system with turbine blowers to facilitate dewatering. The vacuum level, which is controlled by motor speed, must be continuously monitored. In addition, to ensure safe vacuum pump/blower operation, the lubrication status of bearings is maintained by measuring lubricant pressure and reservoir level.

more info...

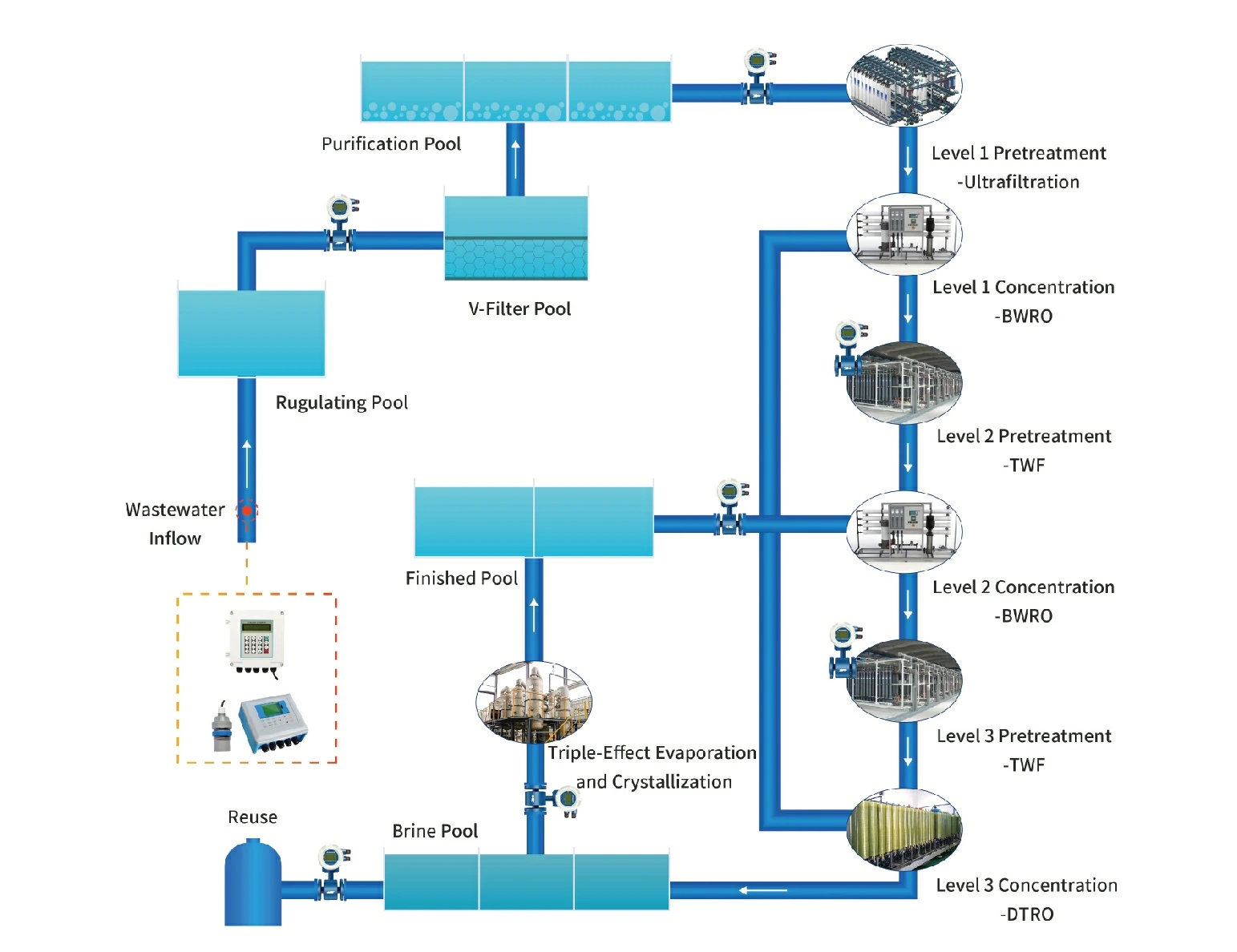

In response to the national sustainable development strategy, enterprises typically install industrial wastewater treatment equipment, such as electromagnetic flowmeters and open channel flowmeters, to monitor and measure wastewater treatment and discharge.

more info...