High Pressure Range Pressure Sensor

Φ12.6x10.5mm

0bar~1bar…1000bar

-10~80℃ Compensated

MPM480

Used For

Mechanical Manufacturing, Hydraulic and Pneumatic Control Technology, Marine Industry, Petroleum and Petrochemical Industry, Natural Gas Industry, Municipal and Environmental Engineering

Leave a MessageMPM480 LED Display Pressure Transmitter provides various pressure interface forms such as sanitary type, anti-corrosion type and flush membrane type. The pressure transducer of the output signal can be adjusted on-site and displayed on the LED screen. The product meets EMI protection requirements and has excellent reliability and flexibility. MPM480 is one of Micro Sensor's national patented pressure transducers. The pressure transducer with display is suitable for pressure measurement at industrial process sites.

Features

• Support reversed-polarity, overcurrent and

• overvoltage protection, conforming EMI

• Intrinsic safety type, Ex ia IIC T6 Ga

• Explosion-proof type, Ex db IIC T6 Gb

Specifications

• Measurement Range: -1bar…0mbar ~ 100mbar…1000bar

• Operation Temp.: -30℃ ~ 80℃

• Long-term Stablity: ±0.2%FS/year

Image:

MPM480 LED Display Pressure Transmitter provides various pressure interface forms such as sanitary type, anti-corrosion type and flush membrane type. The pressure transducer of the output signal can be adjusted on-site and displayed on the LED screen. The product meets EMI protection requirements and has excellent reliability and flexibility. MPM480 is one of Micro Sensor's national patented pressure transducers. The pressure transducer with display is suitable for pressure measurement at industrial process sites.

Features

• Support reversed-polarity, overcurrent and

• overvoltage protection, conforming EMI

• Intrinsic safety type, Ex ia IIC T6 Ga

• Explosion-proof type, Ex db IIC T6 Gb

Specifications

• Measurement Range: -1bar…0mbar ~ 100mbar…1000bar

• Operation Temp.: -30℃ ~ 80℃

• Long-term Stablity: ±0.2%FS/year

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.5%FS

ModBus-RTU Protocol

Heavy Duty & Shock Resistance

16Bar~1000Bar

Accuracy:±1%FS

Pressure type: Gauge

Range: 0.1bar~25bar

Output signal: 4~20mA, 4~20mA+HART, Modbus-RTU/RS485 and others

Reference accuracy: ±0.2% upper range limit, maximum ±0.5% upper range limit

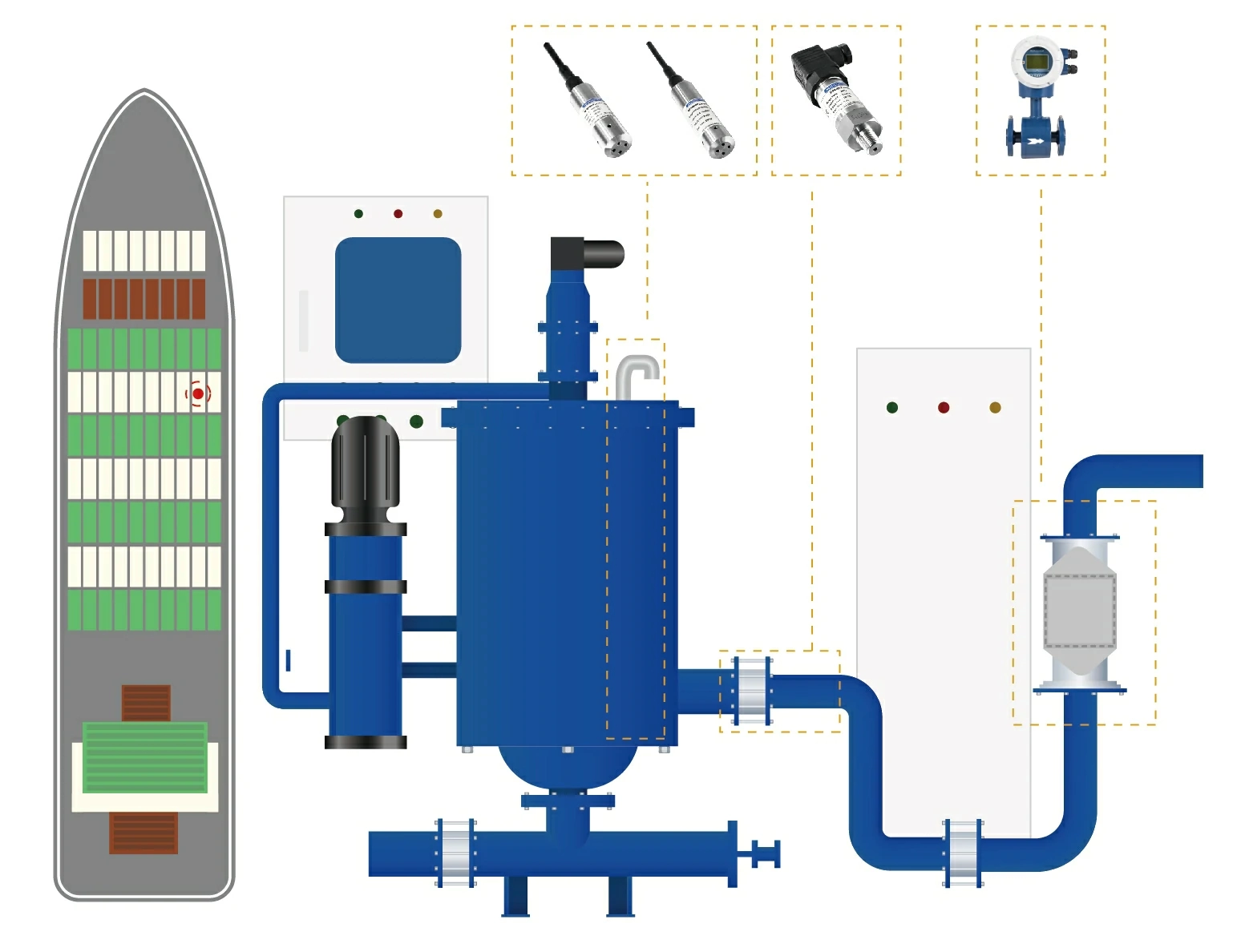

Ballast tank level monitoring achieves precise control of the ballast water system by using equipment such as electromagnetic flowmeters, level transmitters, and pressure transmitters to monitor data on inflow, tank liquid level, and pressure.

more info...

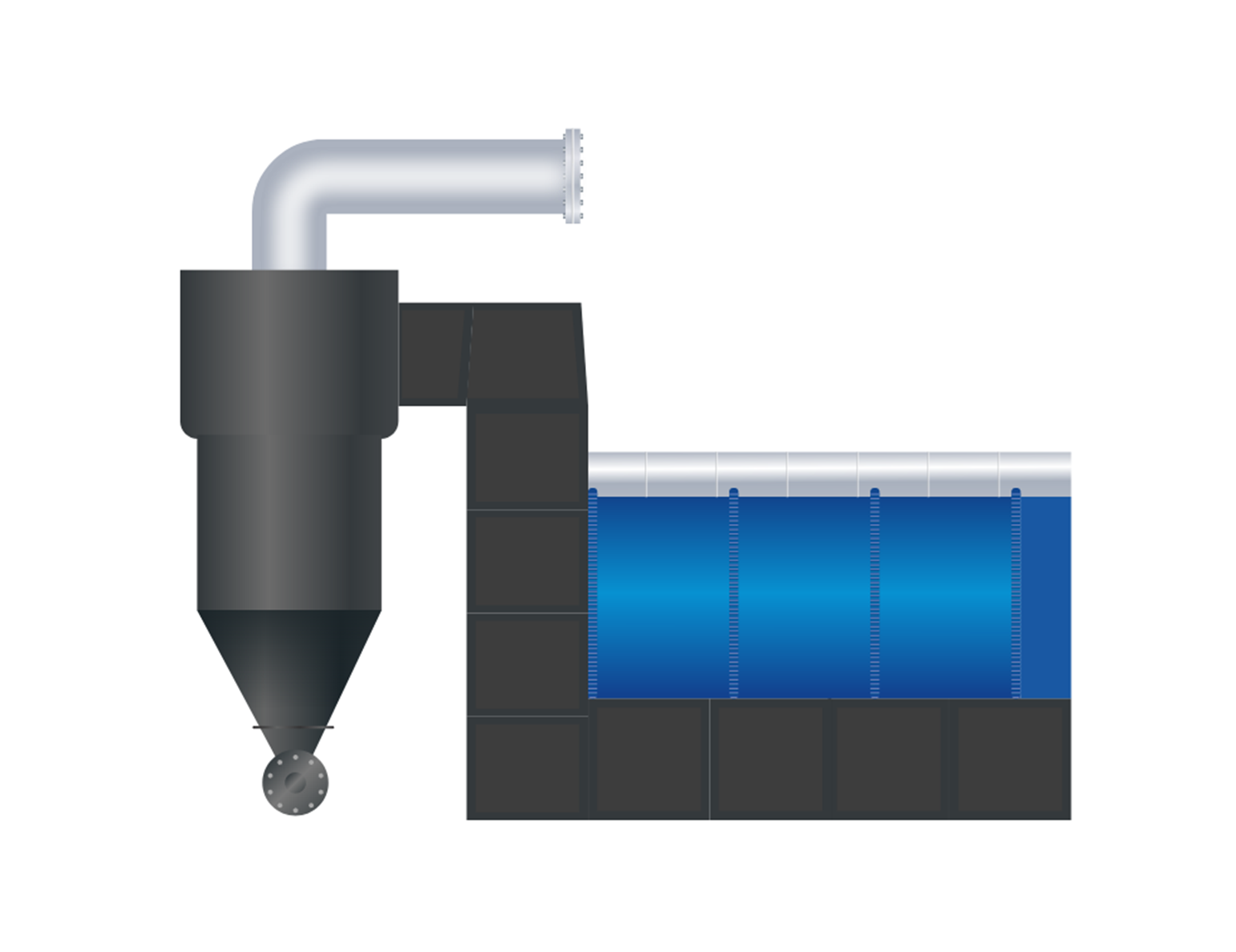

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...

Oil is a high-quality energy and chemical raw material. That is, the "blood of industry". There are various challenges due to different environmental climates and storage conditions all over the world, as well as various unforeseen situations in the process of monitoring of oil tanks.

more info...

To eliminate any remaining moisture in the paper web, the paper machine's drying section uses rollers heated by steam. The inner cylinder surface develops a condensate coating as the steam loses heat, which affects the heat transfer to the paper. Continuous siphoning is required to remove this condensate. Pressure measurements at the cylinder inlet and outlet monitor the appropriate heat transfer level to the paper.

more info...