Pressure Transmitter for Electronic Industry

Pressure type: Gauge

Range: -1bar~15bar; -1bar~35bar; -1bar~210bar

Accuracy: ±0.5%FS

MPM460

Used For

Chemical, Metallurgy, Water Supply and Drainage, Power Plants

Leave a MessageMPM460 pressure controller with local LED display, supports relay signal, analog or Modbus output. Maximum 5 controlling points. MPM460 transmitting switch could measure and control pressure accurately in the harsh environment. The device has the capability to use RS485 networking for transmitting data and displaying local measurements. Additionally, it can deliver analog standard signals or relay control signals as required.

Features

• Precise measurement and control of pressure, differential pressure and liquid level

• The protection level of the whole machine reaches IP65

• Suitable for open-air environments and harsh sites

• RS485 bus form networking

Specifications

• Output signal: 4~20mADC, 0~10/20mADC or 0/1~5VDC; digital RS485

• Accuracy: +0.25%FS(typ.); +0.5%FS(max.) including analog output’s lin.,rep. and hys.

• Zero temp.drift: +0.03%FS/°C(≤100kPa), +0.02%FS/°C(>100kPa)

• FS temp.drif: t +0.03%FS/°C(≤100kPa), +0.02%FS/°C(>100kPa)

• Long-term stability: ≤+0.5%FS/year

• Relay quantity :1~5

• Load: 240V/5A(AC)or 30V/5A(DC)

Image:

MPM460 pressure controller with local LED display, supports relay signal, analog or Modbus output. Maximum 5 controlling points. MPM460 transmitting switch could measure and control pressure accurately in the harsh environment. The device has the capability to use RS485 networking for transmitting data and displaying local measurements. Additionally, it can deliver analog standard signals or relay control signals as required.

Features

• Precise measurement and control of pressure, differential pressure and liquid level

• The protection level of the whole machine reaches IP65

• Suitable for open-air environments and harsh sites

• RS485 bus form networking

Specifications

• Output signal: 4~20mADC, 0~10/20mADC or 0/1~5VDC; digital RS485

• Accuracy: +0.25%FS(typ.); +0.5%FS(max.) including analog output’s lin.,rep. and hys.

• Zero temp.drift: +0.03%FS/°C(≤100kPa), +0.02%FS/°C(>100kPa)

• FS temp.drif: t +0.03%FS/°C(≤100kPa), +0.02%FS/°C(>100kPa)

• Long-term stability: ≤+0.5%FS/year

• Relay quantity :1~5

• Load: 240V/5A(AC)or 30V/5A(DC)

Pressure type: Gauge

Range: -1bar~15bar; -1bar~35bar; -1bar~210bar

Accuracy: ±0.5%FS

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.15%FS (Typ.)

RS485/HART Protocol

DNV approved for ship use

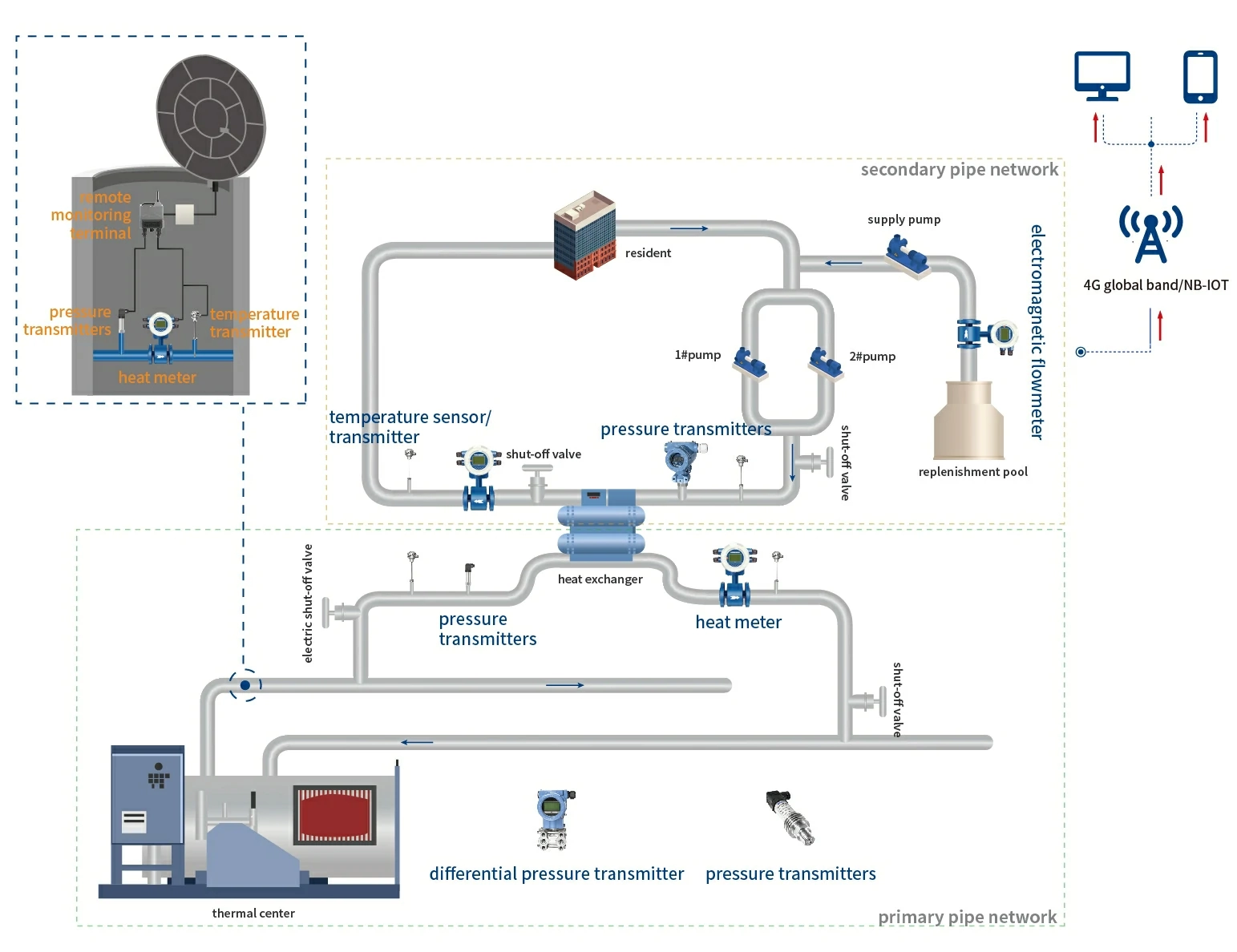

Electromagnetic flowmeters, ultrasonic flowmeters, level transmitters, pressure transmitters are installed in the heat exchange station heating system to obtain real-time data on pipeline flow, heat, temperature, and pressure, ensuring the normal operation of the heat exchange station.

more info...

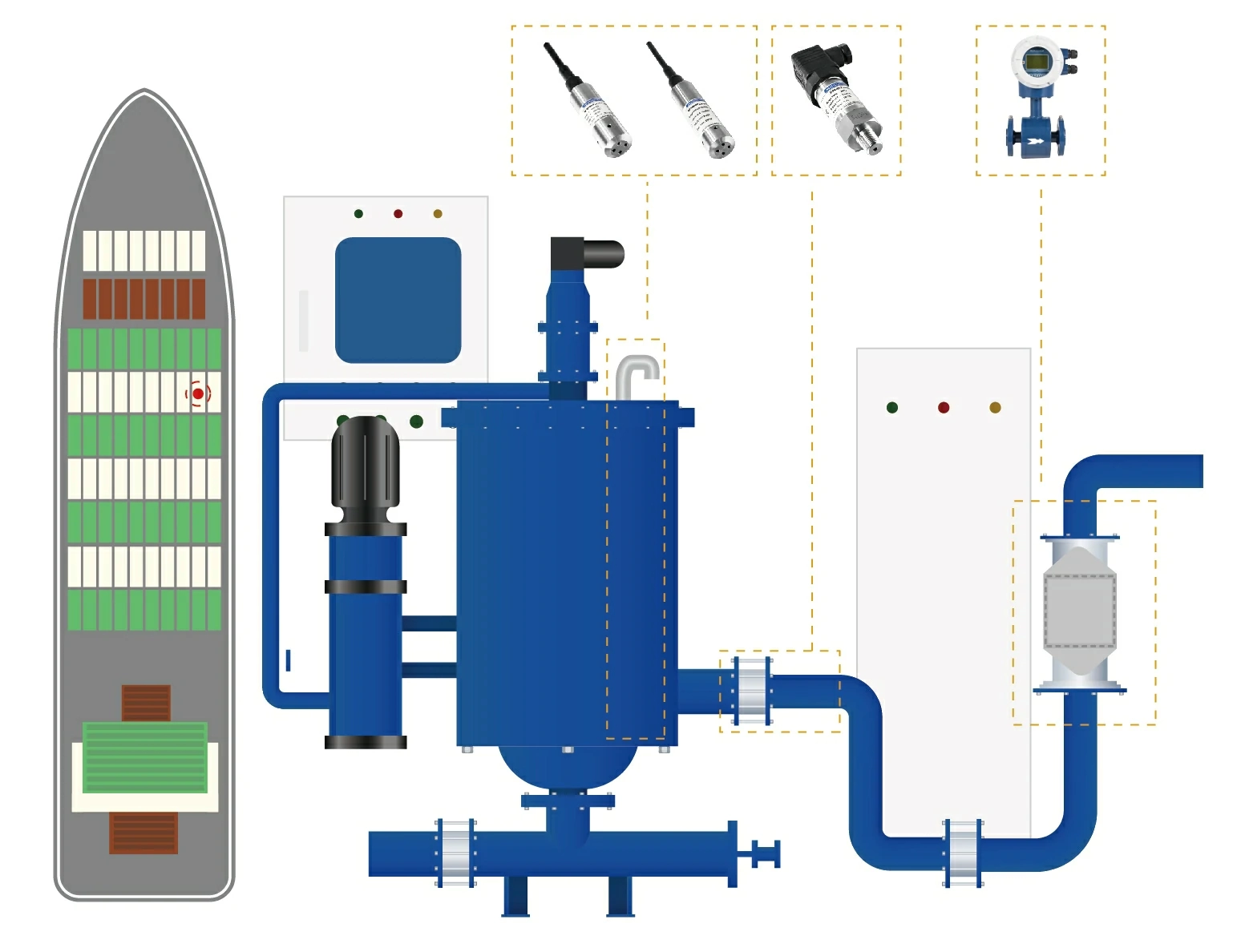

Ballast tank level monitoring achieves precise control of the ballast water system by using equipment such as electromagnetic flowmeters, level transmitters, and pressure transmitters to monitor data on inflow, tank liquid level, and pressure.

more info...

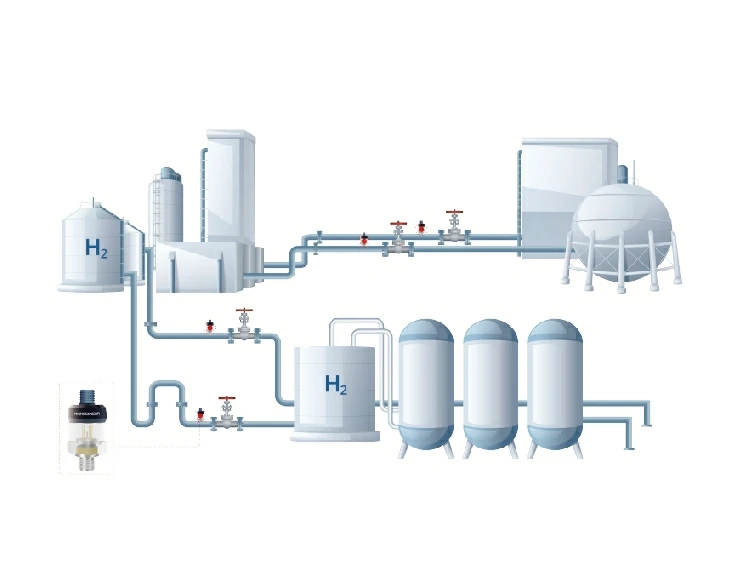

Due to the highly diffusive, flammable, and explosive characteristics of hydrogen, strict pressure monitoring by pressure transmitters is required to ensure its safety during transportation.

more info...

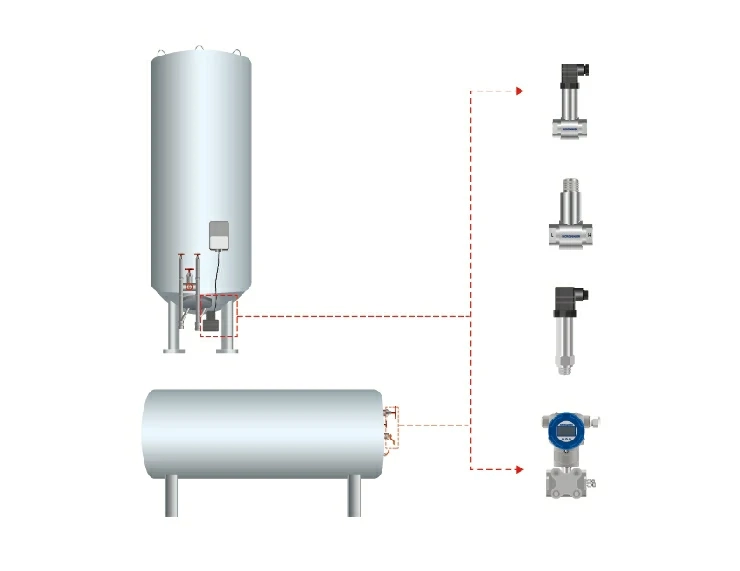

Pressure transmitters are used not only to measure the pressure inside the tank but also to measure the absolute pressure of the tank body and the pressure before and after the cryogenic pump, ensuring the safe operation of the system. Differential pressure measurement is the most common and reliable method for measuring the liquid level of cryogenic high-pressure bulk storage tanks.

more info...