Pressure Transmitter for General Industry

Range:0bar~0.35bar…200bar

Accuracy: ±0.5%FS

CE, RoHS

MDM460

Used For

Liquid and Gas Differential Pressure Measurement, Marine, Aviation, Metrology, Scientific Research

Leave a MessageMDM460 differential pressure controller with local LED display, supports relay signal, analog or Modbus output. Maximum 5 controlling points.

MDM460 intelligent transmitting control could measure and control differential pressure accurately in rugged open environment. It can use RS485 netting and display local measure value, and provide analog standard signal or relay control signal. The product could be used for differential pressure measuring, transmitting, displaying and transforming of chemi-industry, metallurgy, ocean, aviation, measurement, science, etc.

Features

• RS485 semi-duplex communication interface to transmit data signal and do long-distance calibration; easy for netting and connecting with MODEM interface to achieve data wireless transmitting

• Using piezoresistive pressure/differential pressure sensor and digital correction compensation; high accuracy

• Strict testing and aging, stable performance; aluminum-alloy electronic housing; IP65 Protection

• Key setting and calibration, easy installation

• LED measuring value display and LCD status information display

• Max.5 relay to control

• Optional pressure port and standard output signal

Specifications

• Pressure range: 0~35kPa…3.5MPa

• Static pressure: ≤20MPa

• Output signal: analog 4~20mADC, 0~10/20mADC or 0/1~5VDC; digital RS485

• Accuracy: +0.25%FS(typ.); +0.5%FS (max.) including analog output’s lin.,rep. and hys.

• Zero temp.drift :+0.03%FS/℃ (≤100kPa), +0.02%FS/℃ (>100kPa)

• FS temp.drift: +0.03%FS/℃ (≤100kPa), +0.02%FS/℃ (>100kPa)

• Long-term stability: ≤+0.5%FS/year

• Power supply: 220VAC±15% or 220VDC or 24VDC

• Max. consumption: ≤3.5W

• Environment temp.: -10℃~60℃

• Media temp.: -10℃~80℃

• Acceleration: ≤3×9.81ms-2

• Storage temp.: -40℃~125℃

Image:

MDM460 differential pressure controller with local LED display, supports relay signal, analog or Modbus output. Maximum 5 controlling points.

MDM460 intelligent transmitting control could measure and control differential pressure accurately in rugged open environment. It can use RS485 netting and display local measure value, and provide analog standard signal or relay control signal. The product could be used for differential pressure measuring, transmitting, displaying and transforming of chemi-industry, metallurgy, ocean, aviation, measurement, science, etc.

Features

• RS485 semi-duplex communication interface to transmit data signal and do long-distance calibration; easy for netting and connecting with MODEM interface to achieve data wireless transmitting

• Using piezoresistive pressure/differential pressure sensor and digital correction compensation; high accuracy

• Strict testing and aging, stable performance; aluminum-alloy electronic housing; IP65 Protection

• Key setting and calibration, easy installation

• LED measuring value display and LCD status information display

• Max.5 relay to control

• Optional pressure port and standard output signal

Specifications

• Pressure range: 0~35kPa…3.5MPa

• Static pressure: ≤20MPa

• Output signal: analog 4~20mADC, 0~10/20mADC or 0/1~5VDC; digital RS485

• Accuracy: +0.25%FS(typ.); +0.5%FS (max.) including analog output’s lin.,rep. and hys.

• Zero temp.drift :+0.03%FS/℃ (≤100kPa), +0.02%FS/℃ (>100kPa)

• FS temp.drift: +0.03%FS/℃ (≤100kPa), +0.02%FS/℃ (>100kPa)

• Long-term stability: ≤+0.5%FS/year

• Power supply: 220VAC±15% or 220VDC or 24VDC

• Max. consumption: ≤3.5W

• Environment temp.: -10℃~60℃

• Media temp.: -10℃~80℃

• Acceleration: ≤3×9.81ms-2

• Storage temp.: -40℃~125℃

Range:0bar~0.35bar…200bar

Accuracy: ±0.5%FS

CE, RoHS

Applicable for Hydraulic and Pneumatic

0bar~16bar …350bar

Accuracy:±0.5%FS

Widely used in the medical and pharmaceutical industry for oxygen measurement

All-welded design

Fully digital temperature compensation calibration

Adapted to breathable membranes

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

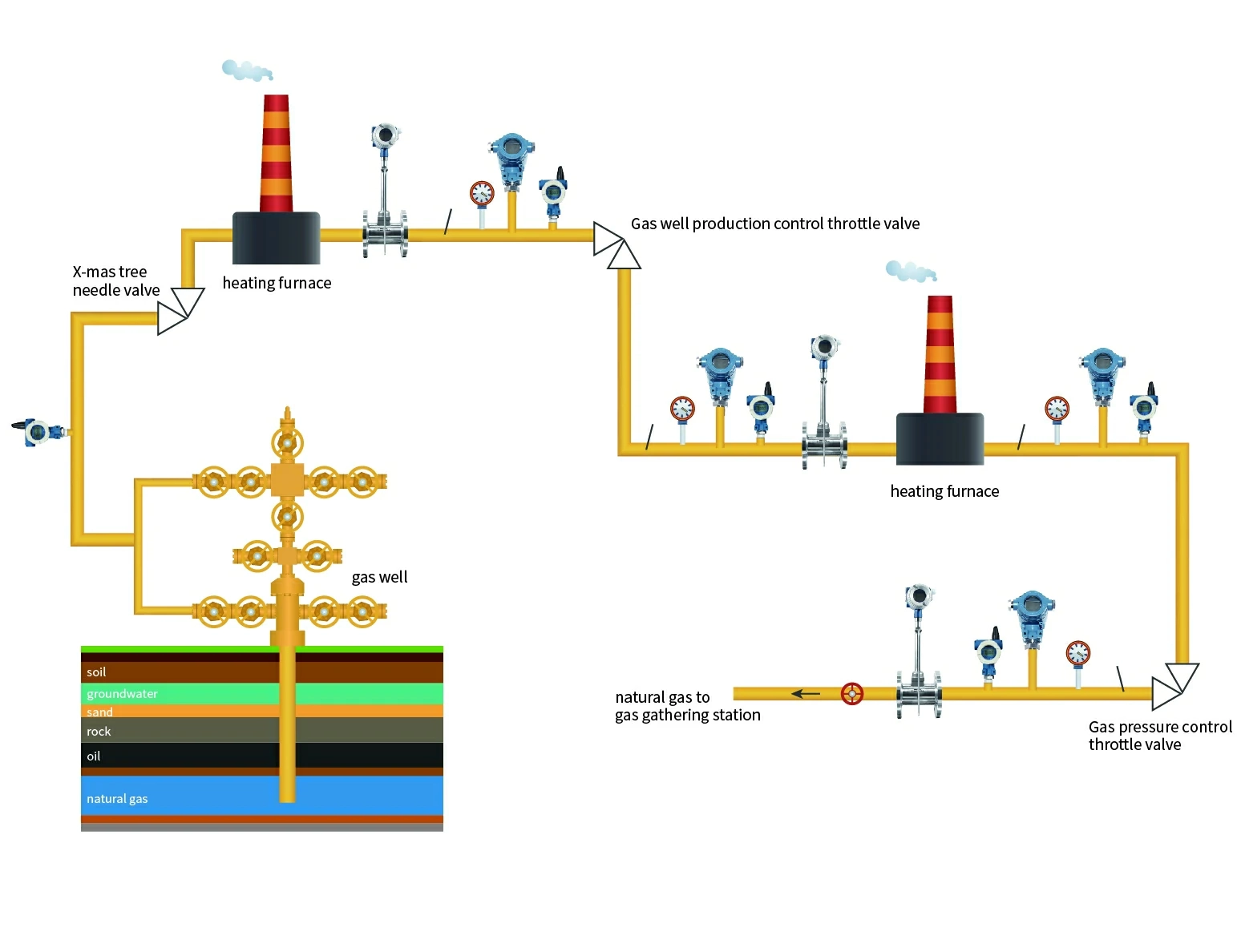

Centralizing the oil and gas produced by scattered oil wells, processing and initial processing, and exporting it after meeting the standards. The process requires multiple steps, including oil and gas separation, crude oil dehydration, and natural gas purification, thus requiring various instruments to measure production parameters.

more info...

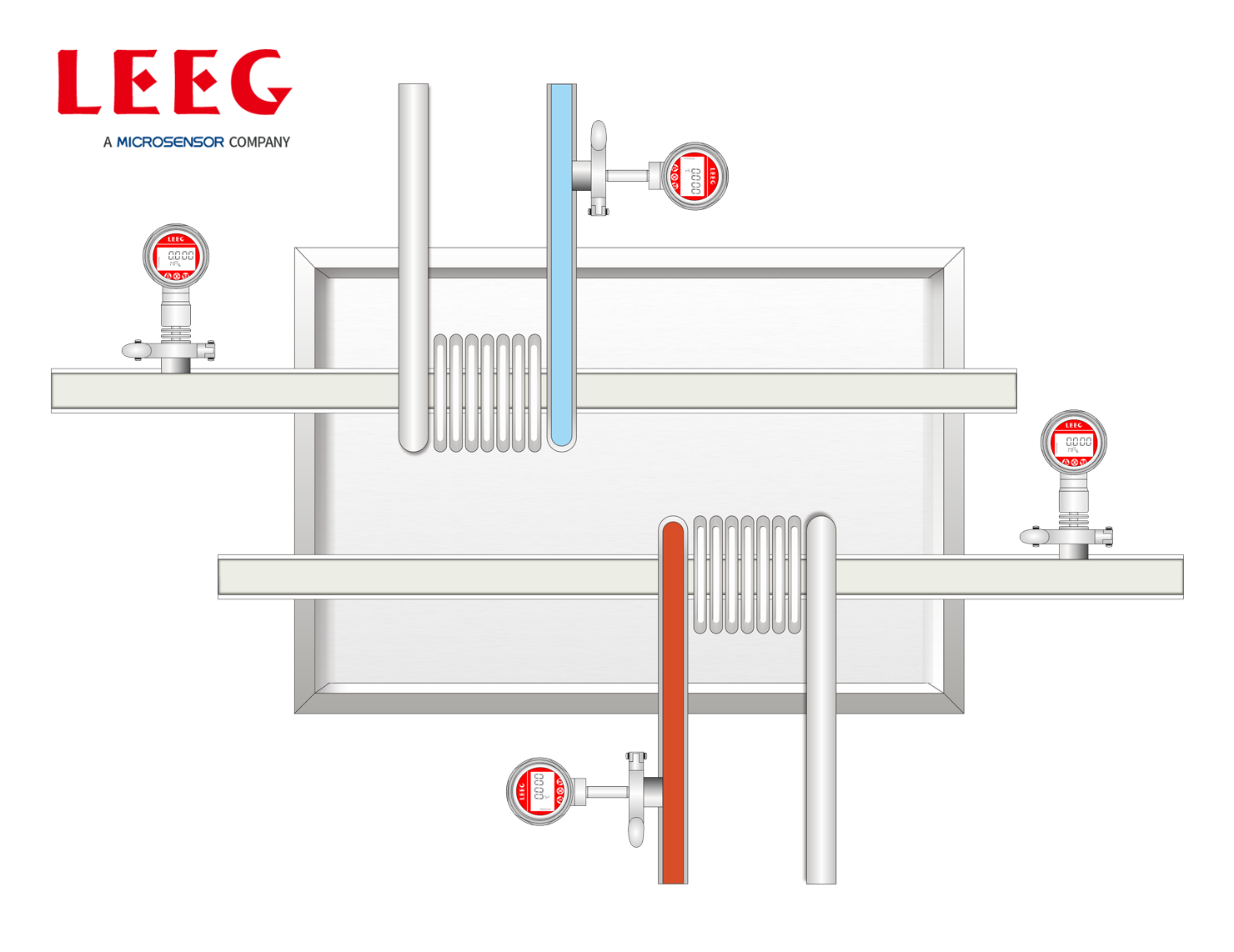

In beverage production and dairy processing, liquids are heated to specified temperatures through heat exchange, followed by rapid cooling to eradicate pathogens and prolong shelf life. Multiple stages such as heating and cooling of wort ensure that beer reaches the appropriate temperature for yeast cultivation. Both the cooler and preheater require monitoring of temperatures in the cooling and preheating tubes, as well as the pressure in the food pipelines.

more info...

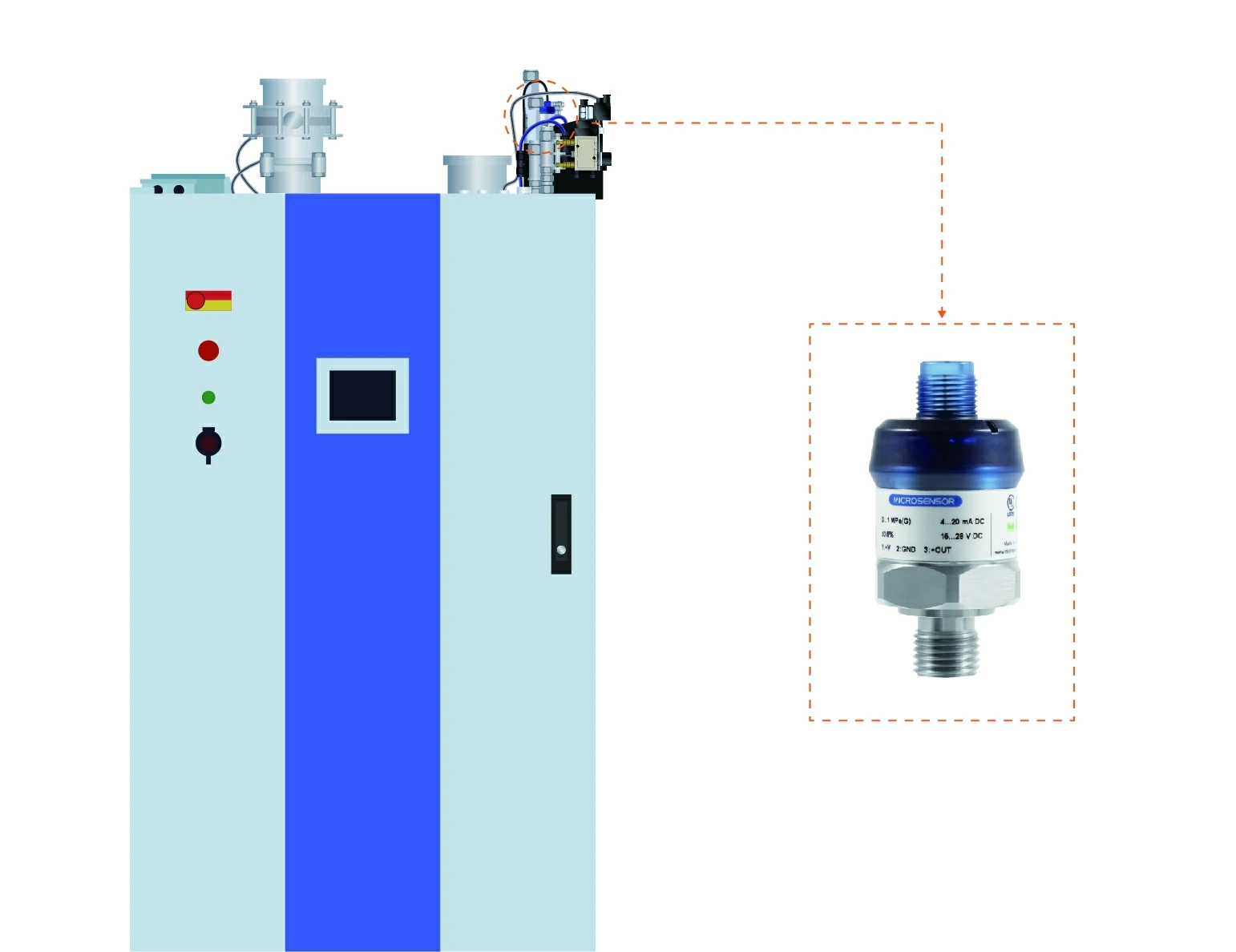

The plasma in a plasma cleaning machine is a state of matter, usually composed of process gases. Therefore, specially designed pressure transmitters must be installed in the relevant gas circuits of the plasma cleaning system to monitor and provide feedback on production data.

more info...

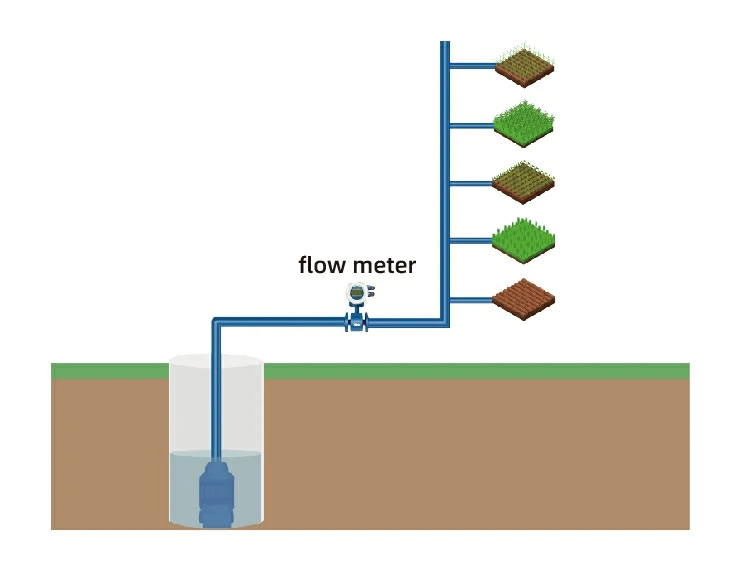

Pipelines are the most common water transportation and irrigation facilities. During transportation, pipelines effectively reduce evaporation and leakage of water resources. Monitoring instruments measure accurately discharge flow. It is a crucial action of rational water resource allocation and reasonable water fee collection.

more info...