Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

MPM460W

Used For

Chemical-industry, Metallurgy, Measurement, Environmental Protection

Leave a MessageThe MPM460W Level Transmitting Controller is designed to measure and control liquid levels in harsh environments precisely. It utilizes an RS485 networking system and displays precise local measurements. Additionally, this controller offers analog standard signals or relay control signals for enhanced versatility. The pressure element ensures high accuracy with digital correction compensation. Each batch of products is strictly tested and aged.

Feature

• Digital RS485 and 4-20mA output

• Easy to set up and calibrate

• Enables wireless data transmission

Specifications

• Pressure range: 0~1…200mH2O

• Overpressure: 1.5 times FS

• Sensor part housing protection: IP68

• Output signal: Analog 4~20mADC, 0~10/20mADC or 0/1~5VDC; digital RS485

Image:

The MPM460W Level Transmitting Controller is designed to measure and control liquid levels in harsh environments precisely. It utilizes an RS485 networking system and displays precise local measurements. Additionally, this controller offers analog standard signals or relay control signals for enhanced versatility. The pressure element ensures high accuracy with digital correction compensation. Each batch of products is strictly tested and aged.

Feature

• Digital RS485 and 4-20mA output

• Easy to set up and calibrate

• Enables wireless data transmission

Specifications

• Pressure range: 0~1…200mH2O

• Overpressure: 1.5 times FS

• Sensor part housing protection: IP68

• Output signal: Analog 4~20mADC, 0~10/20mADC or 0/1~5VDC; digital RS485

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

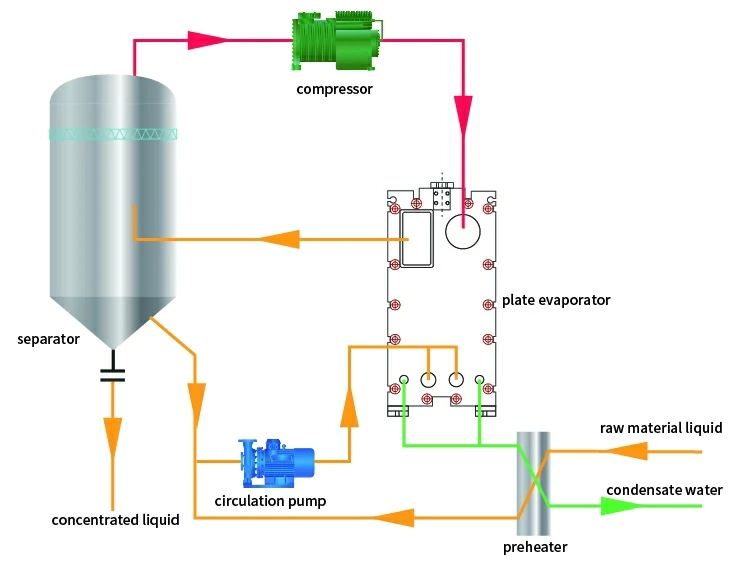

The MVR evaporation equipment requires the use of intelligent pressure transmitters to monitor the liquid level in the separator for feed control. It also monitors the liquid level in the condensate tank, providing timely water replenishment for the condenser, allowing it to condense rapidly. Concurrently, the liquid level height of the raw material tank and the mother liquor tank is monitored. When the liquid level is depleted, raw liquid is added to maintain the normal progress of the process. Intelligent temperature transmitters are used to monitor the steam temperature in the heater, continuously heating the raw liquid for the separation of the solution and the solute. It also monitors the temperature of the separator cavity for efficient separation of the solute and solvent. Flowmeters are used to calculate the volume of the raw material liquid in the feed pump, accumulating the flow.

more info...

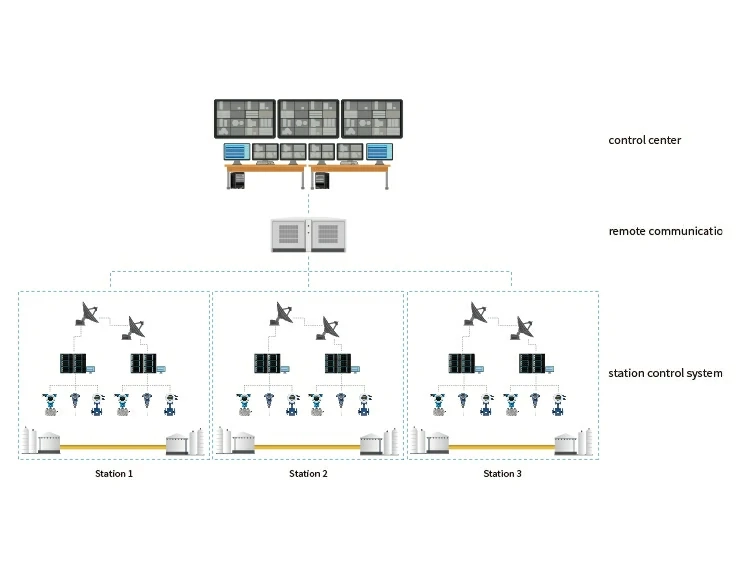

During the process of oil and gas transportation, it is necessary to collect and analyze production and security data related to pipelines and production sites, and generally a supporting SCADA system needs to be built simultaneously. The SCADA system can monitor, control and manage the flow rate, pressure and temperature of the entire pipeline in real time, in order to achieve safe transportation, reduce consumption and improve economic efficiency.

more info...

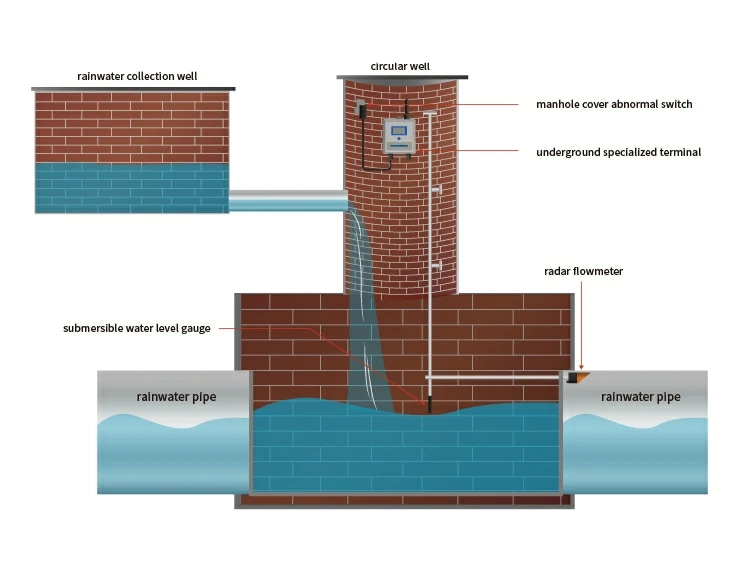

Sump wells are important facilities for convenient daily inspection, prevention, and dredging of drainage pipe blockages. By deploying monitoring instruments at the bottom of the well, a comparison of drainage volume and rainfall is made, allowing for the prediction of flooding points and drainage times under real-time changing drainage conditions. When the water level data exceeds the preset warning value, a timely alarm is given, effectively preventing urban flooding.

more info...

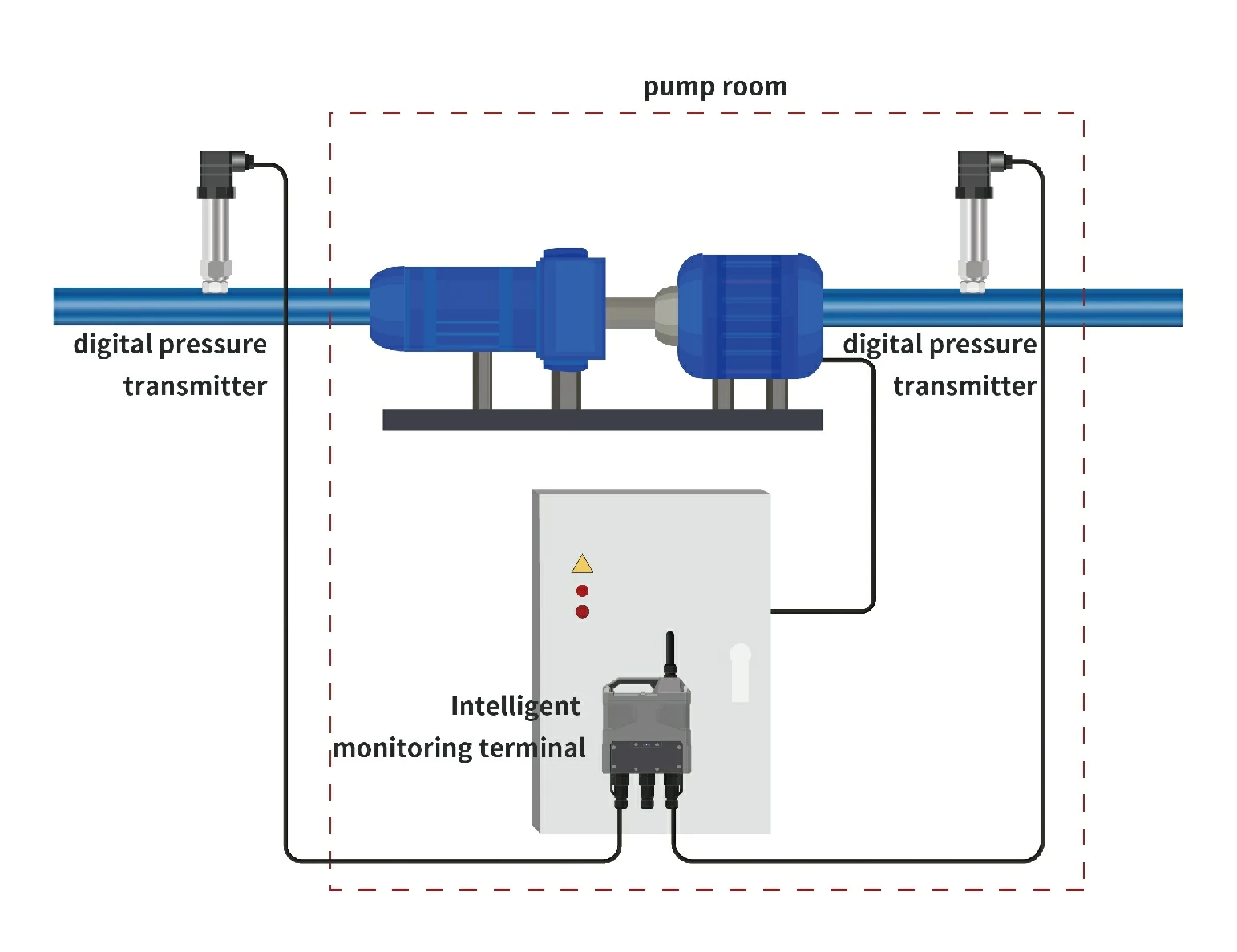

Various monitoring instruments are installed in the water storage tanks, pools, and pipelines of the water supply pump station to monitor the operation of the facilities in real-time. Through advanced cloud computing and big data technology, production data is integrated for timely alarms and early warnings.

more info...