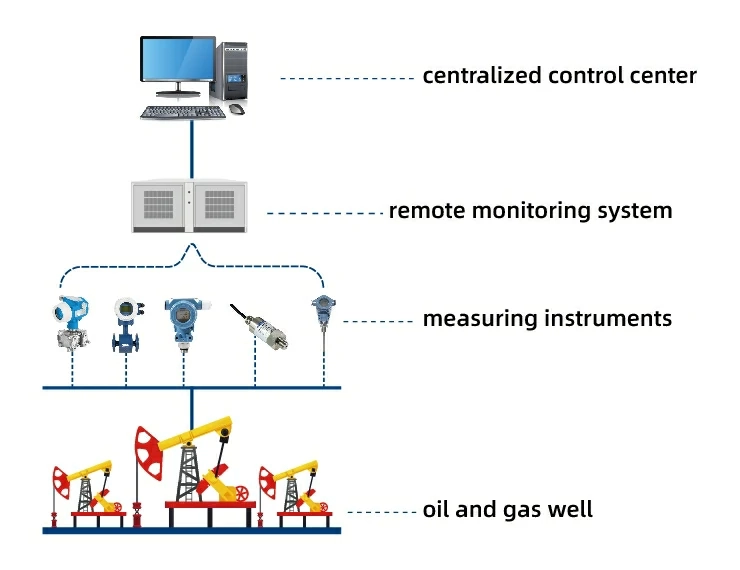

Oil and Gas Wells Remote Monitoring

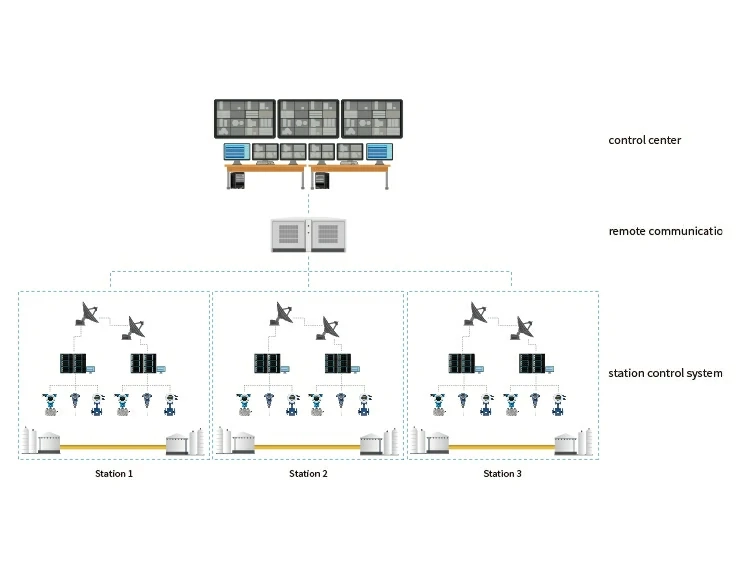

To accurately obtain information about fluid properties, oil layer depth, and other parameters during exploration and extraction, it is necessary to measure formation pressure, fluid density, temperature, and other factors. These data can be remotely transmitted to an online dispatch platform, connected with other oil and gas wells, and integrated into a dedicated IoT network for the oil field. This enables automatic data collection and remote control of oil well production, achieving unified scheduling and intelligent management of oil well production.

more info...

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD