Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.5%FS

DNV approved for installation on all vessels

ATEX Certificated

MPM5589

Used For

Water Treatment, Water Supply and Sewage

Leave a MessageThe MPM5589 level switch is a highly intelligent level controller that comes with switch signal, analog, or Modbus output options. It offers an adjustable measuring range of 25% to 100% FS and boasts a body and display that can be rotated for easy viewing in different installation positions. This instrument gathers level measuring, local display, and control into an easy-to-use system. It adopts an advanced, industrial-grade MCU as its core. The high-quality pressure sensor allows for quick response, excellent electromagnetic compatibility, and high accuracy. Its separated construction of probe and display makes installation and data-reading a breeze, and users can set liquid density to measure media level of different densities by simply pressing a few keys.

Feature

• Measuring the level of oil and liquid

• Easy installation and data-reading

• 25~100% FS tunable measurement range

• Functions of delay, range drift

Specifications

• Range: 1mH2O, 3mH2O, 5mH2O

• Range Drift: 25%FS~100%FS

• Accuracy: <2%FS

• Hysteresis: ±0.1%FS

• Power supply: 12V~30VDC

• Thermal error: ±0.02%FS/℃ (Zero/FS)

Image:

The MPM5589 level switch is a highly intelligent level controller that comes with switch signal, analog, or Modbus output options. It offers an adjustable measuring range of 25% to 100% FS and boasts a body and display that can be rotated for easy viewing in different installation positions. This instrument gathers level measuring, local display, and control into an easy-to-use system. It adopts an advanced, industrial-grade MCU as its core. The high-quality pressure sensor allows for quick response, excellent electromagnetic compatibility, and high accuracy. Its separated construction of probe and display makes installation and data-reading a breeze, and users can set liquid density to measure media level of different densities by simply pressing a few keys.

Feature

• Measuring the level of oil and liquid

• Easy installation and data-reading

• 25~100% FS tunable measurement range

• Functions of delay, range drift

Specifications

• Range: 1mH2O, 3mH2O, 5mH2O

• Range Drift: 25%FS~100%FS

• Accuracy: <2%FS

• Hysteresis: ±0.1%FS

• Power supply: 12V~30VDC

• Thermal error: ±0.02%FS/℃ (Zero/FS)

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.5%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Fully welded structure, FFKM sealing ring and various cables like PUR, PFA optional

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Magnetic end cap for mobile tanks measurement and NPT1/4 male thread connection for side mounting of tank bottom

Low power consumption

ABS, DNV approved for ship use

Accurate monitoring and control of pressure, level, temperature, and flow are essential in the chemical industry to ensure product quality and production safety. In-depth monitoring solutions from Micro Sensor offer an extensive range of cutting-edge sensors and smart control instruments that can precisely and in real-time monitor these crucial specifications. Data integration and analytics are also used to optimize the production process.

more info...

Inkjet printers are common equipment in the packaging and printing industry. Utilizing continuous inkjet technology, real-time pressure monitoring and early warning are necessary to ensure continuous and stable ink ejection, guaranteeing print quality.

more info...

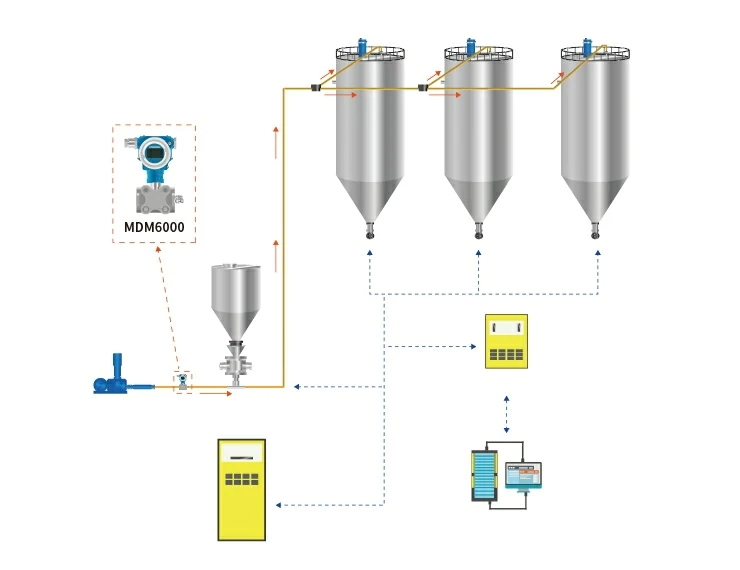

The production of positive and negative electrode materials for lithium cell requires the transmission of powdered materials. The sealed pipelines realize pneumatic transmission of solid powder or particles. However, blockages can occur in the container when conveying materials with large particle sizes, high viscosity, or poor flow ability. Installed pressure transmitters solve this problem. An abnormal pressure alarm will be triggered to identify the location. This facilitates timely repair of the blockage, ensuring normal production and operation.

more info...

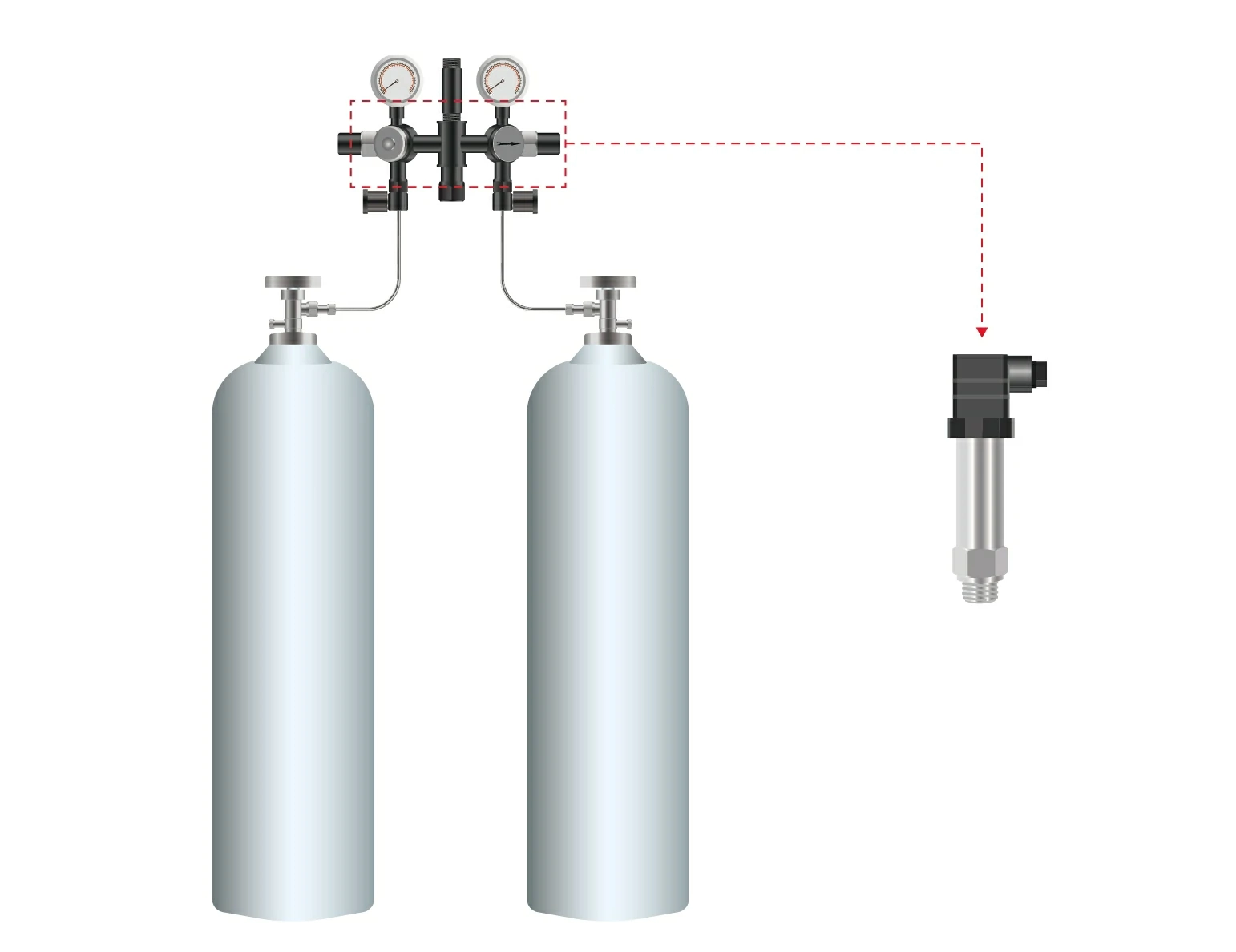

Pressure Transmitters are needed to monitor the pressure in the gas supply pipeline of the compressed gas cylinder to ensure safety.

more info...