Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM416WK

Used For

Hydrostatic Level Measurement in Chemical-Industry, City Water Treatment and Management

Leave a MessageMPM416WK is flange mounted Armoured Level Transmitter. The sensing element is fixed in the armoured tube for stable measurement. Fully sealed stainless steel structure ensure that it is immersed in the liquid to measure the level. With explosion-proof certification, it is suitable for hazardous environments.

Feature

• Liquid static pressure depth measurement

• Certificated with ship-use product and Explosion-proof

• Measurement Pressure range: 1~4mH2O

• Operation temp.: -30℃ ~80℃

• Overpressure: 1.5times FS

• Power supply: 15~28VDC

Specifications

• Pressure range: 1, 2, 3, 4mH2O

• Overpressure: 1.5times FS

• Power supply: 15~28VDC n (Intrinsic safe version is supplied through safe barrier)

Image:

MPM416WK is flange mounted Armoured Level Transmitter. The sensing element is fixed in the armoured tube for stable measurement. Fully sealed stainless steel structure ensure that it is immersed in the liquid to measure the level. With explosion-proof certification, it is suitable for hazardous environments.

Feature

• Liquid static pressure depth measurement

• Certificated with ship-use product and Explosion-proof

• Measurement Pressure range: 1~4mH2O

• Operation temp.: -30℃ ~80℃

• Overpressure: 1.5times FS

• Power supply: 15~28VDC

Specifications

• Pressure range: 1, 2, 3, 4mH2O

• Overpressure: 1.5times FS

• Power supply: 15~28VDC n (Intrinsic safe version is supplied through safe barrier)

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

Perfect coffee needs pressure. Water and steam pressure monitoring of the coffee machine ensures safe and high-quality coffee production. Accurately measuring pressure is required during the coffee bean extraction, hot water delivery, and cleaning of coffee machines.

more info...

The liquid preparation tank is required to prepare various solvents and basic materials for subsequent production, regardless of whether it is to prepare injections, solutions, or detergents, and it needs to proportion different types of purified water, injection water, sucrose solutions, and suspensions. By measuring the liquid level, the filling and dispensing processes are controlled, and pressure measurement is required for the inlet pipelines of different solutions to prevent tank overflow or empty running through measurement.

more info...

Pressure transmitters, temperature tranmitters and electromagnetic flowmeters are installed in the marine water circulation cooling system to ensure the heat exchange efficiency of the central cooler. By optimizing seawater flow control, energy saving effects are maximized and stable operation of the cooling system is ensured.

more info...

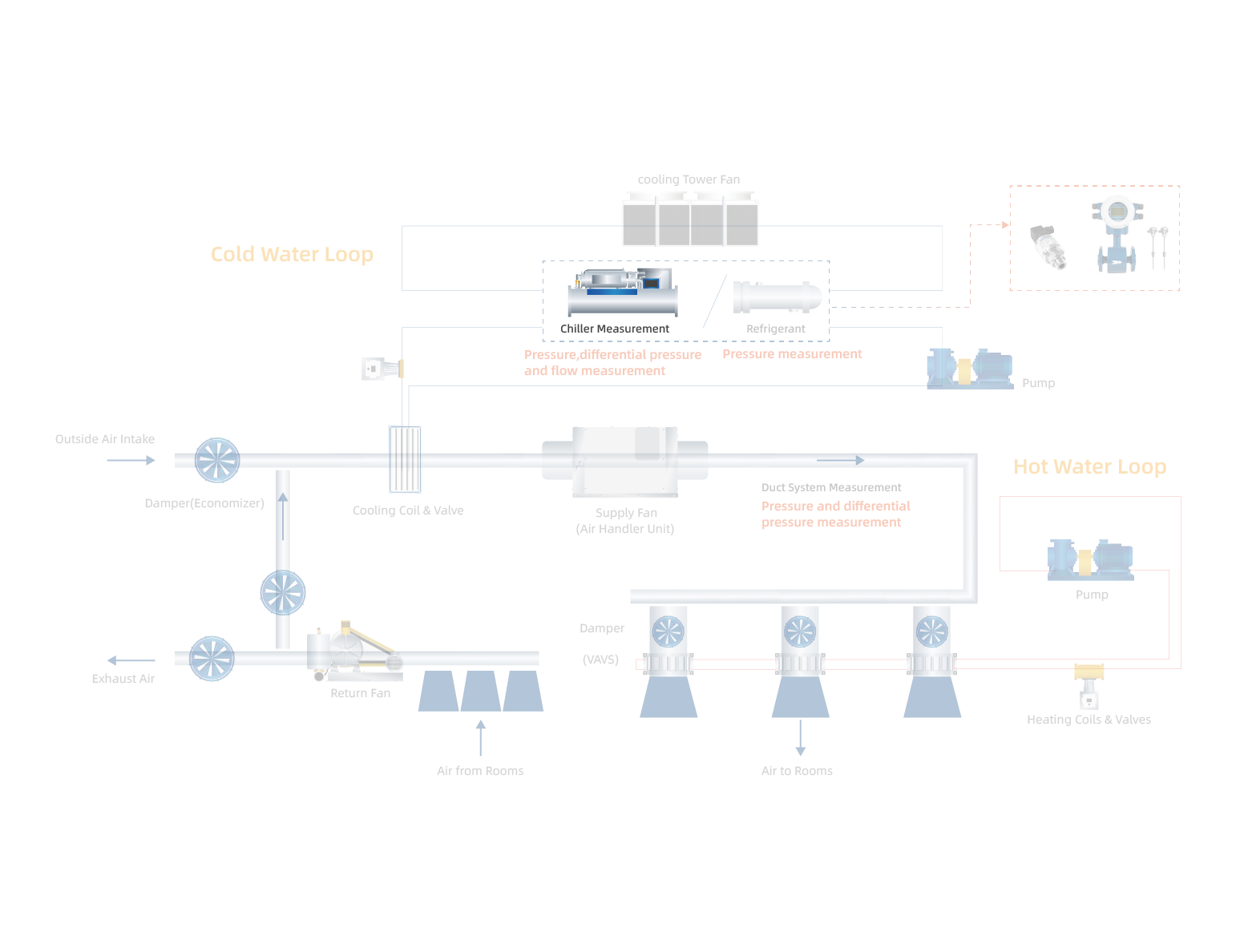

In the HVAC chiller systems, measuring heat and pressure is vital for optimal performance. Pressure transmitters ensure the refrigerant operates within safe limits, while flow meters and temperature sensors calculate heat exchange efficiency. Accurate measurements enhance system reliability, and efficiency, and prevent potential failures.

more info...