Hydrogen Pressure Sensor

Gold plated

SS316L

Gauge, sealed gauge, absolute

MPM4150

Used For

Pump and Sompressor, Refrigerating System, Automatic Testing System, Equipment Matching, Pneumatic System

Leave a MessageThe MPM4150 4-20mA pressure transmitter is designed for the pump and compressor industry. Fully automatic production line ensures stable and reliable products. The product adopts an all-stainless steel structure and is equipped with ceramic pressure-sensitive components inside. The measuring range is 0bar ~ 7bar...35bar. The MPM4150 ceramic pressure sensor is perfect for pressure measurement in hydraulic applications.

Features

• Compact size, Cost efficient

• Various media measurements

• Impact and shock resistance

• Customized OEM available

Specification

• Pressure range: 0bar ~ 7bar…35bar

• Overload: 1.5×FS

• Supply range: 8V ~ 28V DC

• Signal output: 4mA ~ 20mA DC (Two-wire)

• Operation temp.: -20℃ ~85℃

• Non-linearity: ±0.5%

• Storage temp.: -20℃ ~105℃

• Stability: ≤±0.5%FS/Year

• Relative Humidity: 0%~90%

• Shock: 10g, 55Hz~2000Hz

• Vibration: 100g, 11ms

• Insulation resistance: 10MΩ@500VDC

• Protection: IP65

• Media Compatibility: Al2O3 Viton, Stainless Ste304

Image:

The MPM4150 4-20mA pressure transmitter is designed for the pump and compressor industry. Fully automatic production line ensures stable and reliable products. The product adopts an all-stainless steel structure and is equipped with ceramic pressure-sensitive components inside. The measuring range is 0bar ~ 7bar...35bar. The MPM4150 ceramic pressure sensor is perfect for pressure measurement in hydraulic applications.

Features

• Compact size, Cost efficient

• Various media measurements

• Impact and shock resistance

• Customized OEM available

Specification

• Pressure range: 0bar ~ 7bar…35bar

• Overload: 1.5×FS

• Supply range: 8V ~ 28V DC

• Signal output: 4mA ~ 20mA DC (Two-wire)

• Operation temp.: -20℃ ~85℃

• Non-linearity: ±0.5%

• Storage temp.: -20℃ ~105℃

• Stability: ≤±0.5%FS/Year

• Relative Humidity: 0%~90%

• Shock: 10g, 55Hz~2000Hz

• Vibration: 100g, 11ms

• Insulation resistance: 10MΩ@500VDC

• Protection: IP65

• Media Compatibility: Al2O3 Viton, Stainless Ste304

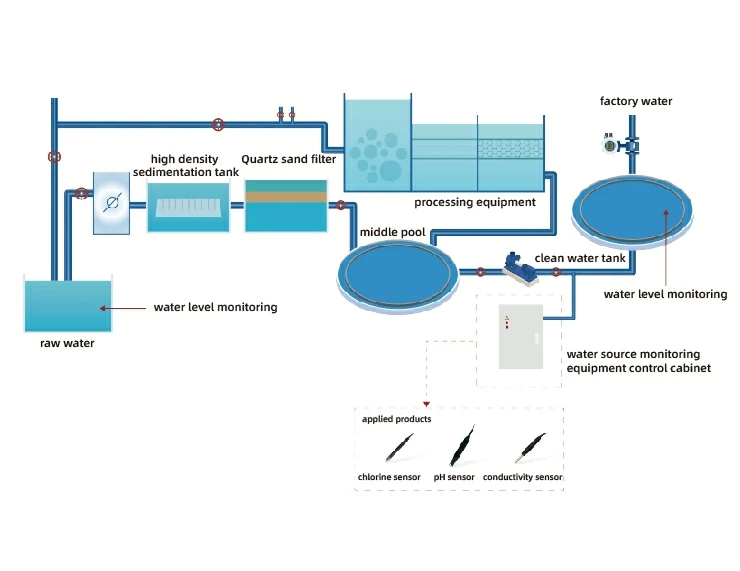

Pressure, flow, and level measuring instruments are deployed in water tanks, pipelines, and water inlets/outlets. This helps to manage the macro-control of production data in the water plant. Measuring instruments ensure smooth operation and normal production.

more info...

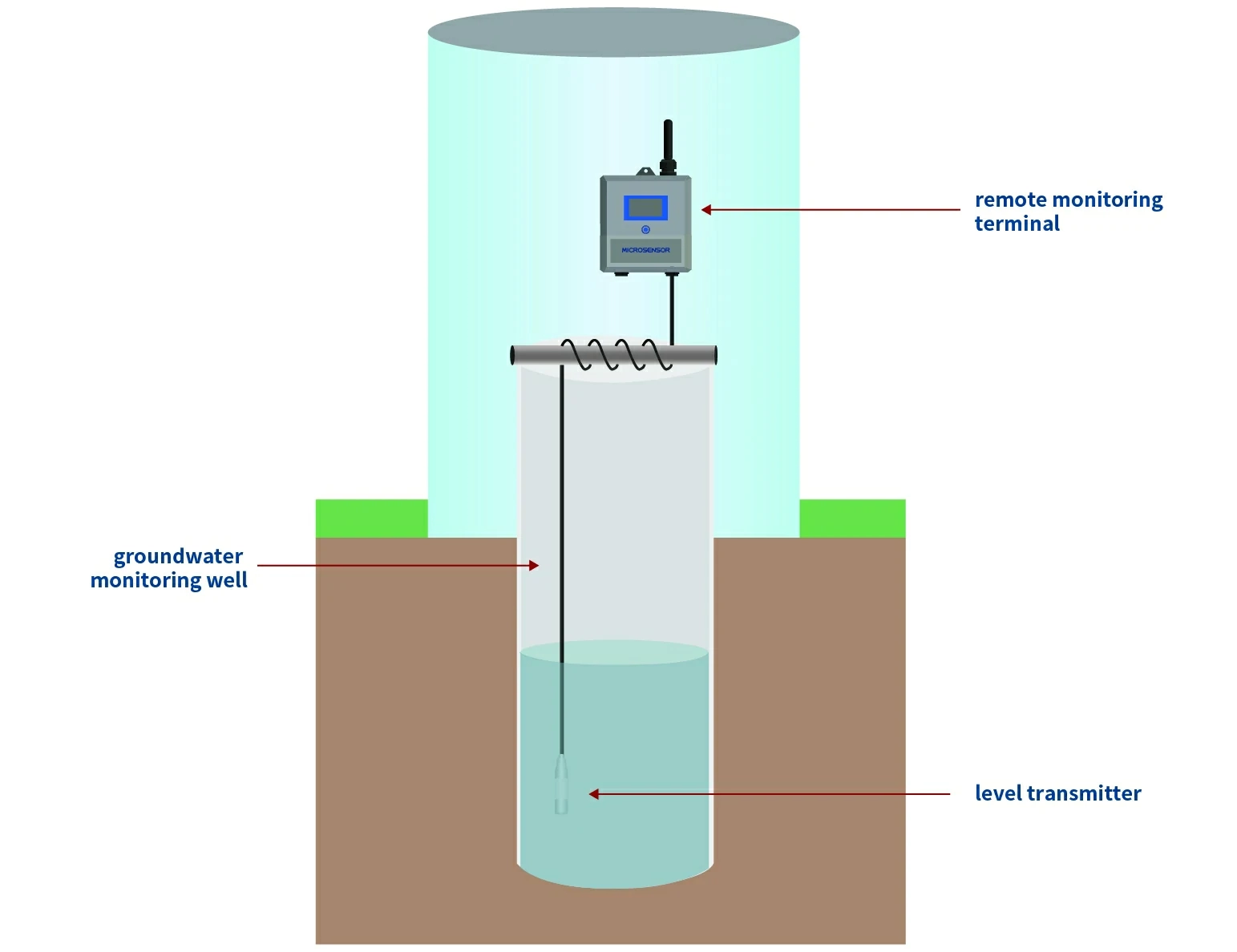

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...

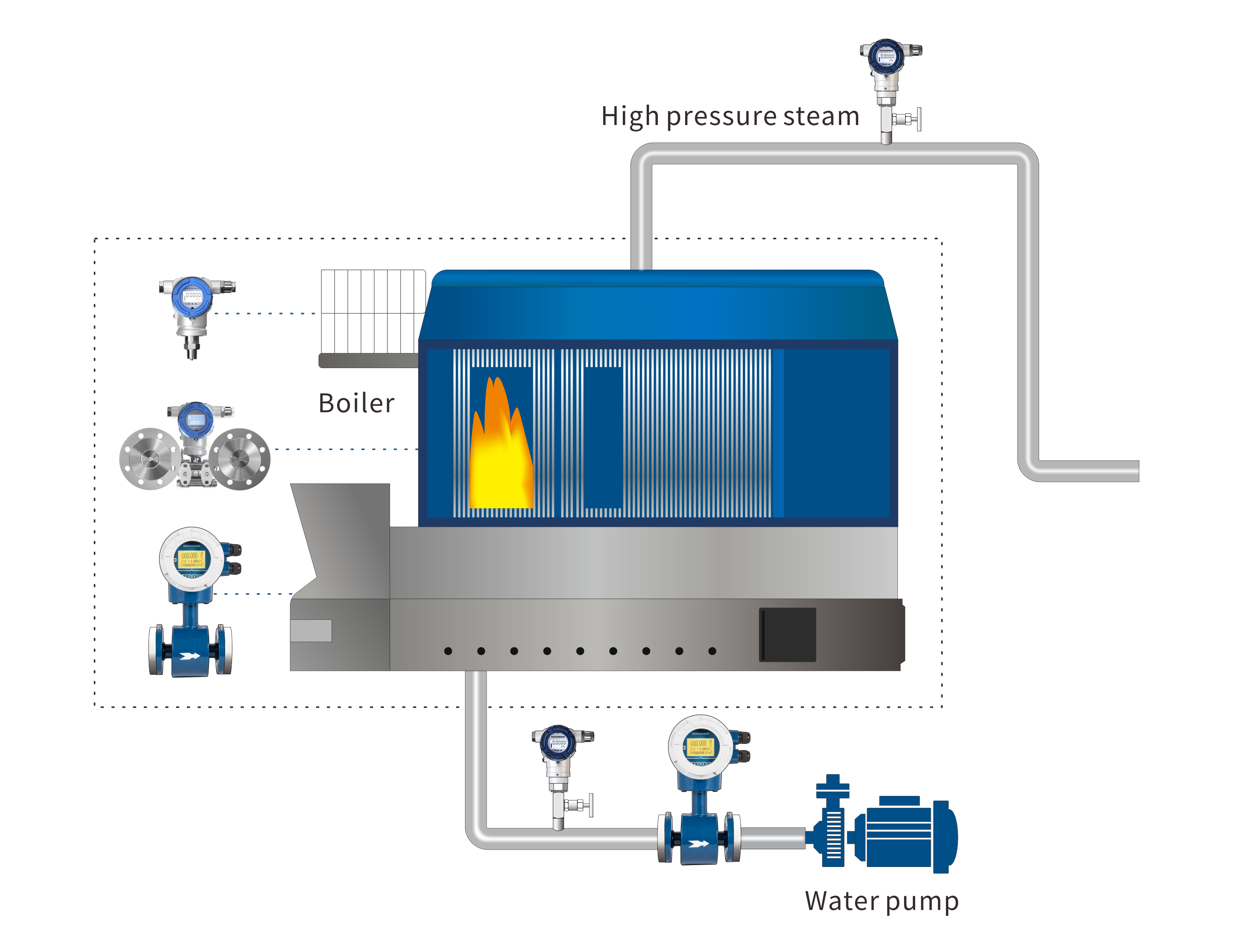

In the electric power industry, especially in power plants and transmission systems, it is very important to accurately monitor and control pressure, level, temperature and flow, because these specifications will directly affect the operating efficiency and safety of the system. Micro Sensor's monitoring instrumentation solutions integrate advanced sensor technology and intelligent control systems, which can provide accurate data and efficient control even in complex environments, and optimize the power production and transmission process.

more info...

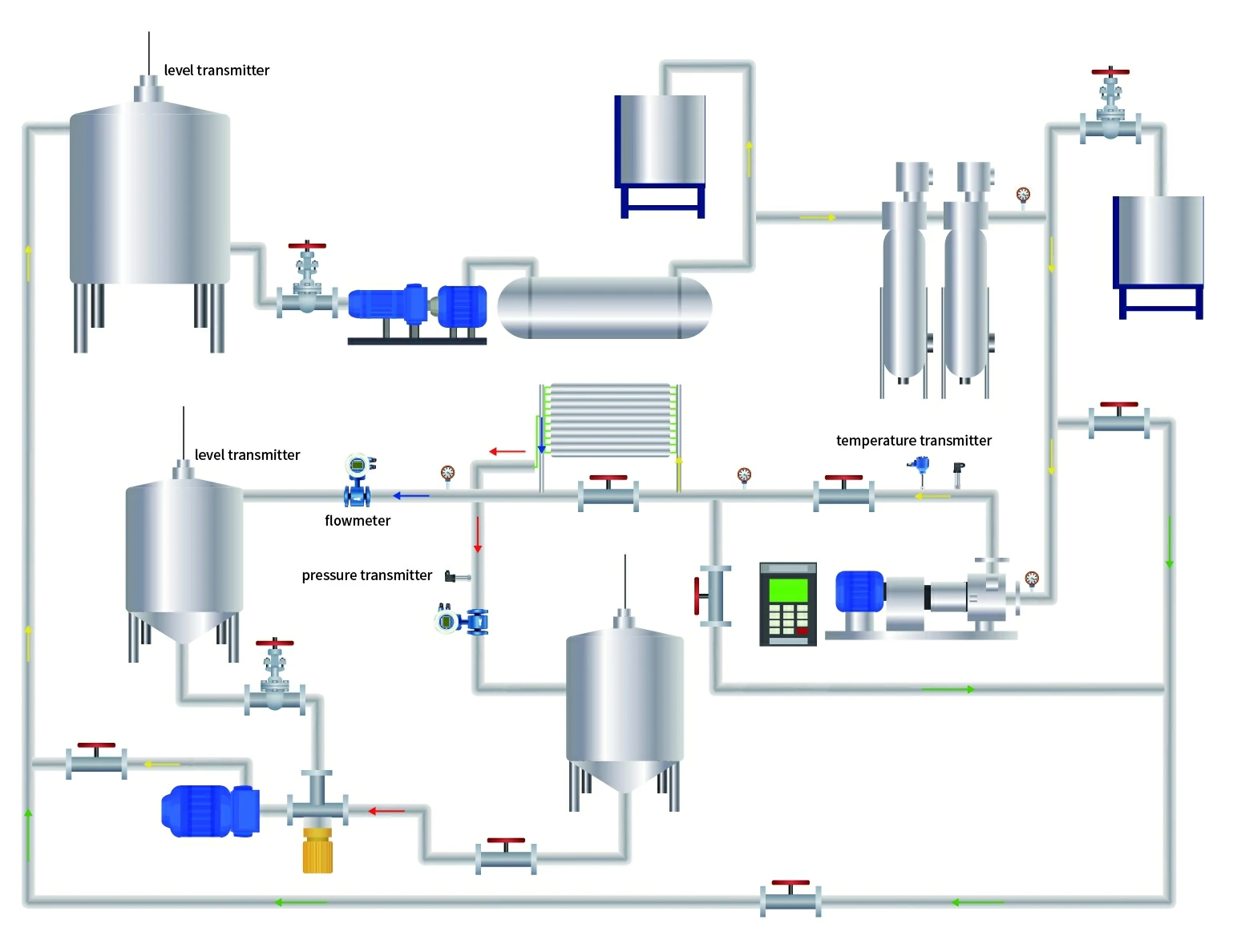

There is a shortage of freshwater resources in coastal or nearshore areas. Desalination is an important solution to water shortages in these areas. During the seawater desalination process, data such as flow rate and liquid level need to be monitored. Monitoring of these data ensures that the system is operating properly.

more info...