Digital RS485 HART Pressure Transmitter

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.15%FS (Typ.)

RS485/HART Protocol

DNV approved for ship use

MDM4760

Used For

Oil and Gas Industry, Power and Energy, Chemical Industry, Food and Beverage

Leave a MessageThe MDM4760 Differential Pressure Transmitter is an advanced digital smart transmitter with special wide-temperature LCD display as well as digital compensation function, compact size, indicator can be rotated 90 degrees clockwise or anticlockwise to provide different interfaces, which not only measures and displays the differential pressure in a timely manner, but also facilitates the user's installation and use, which makes it an ideal choice for accurate measurement of flow pressure.

Features

• Optional data display(max.and min. measure value, percentage and output current display);

• Special wider temperature LCD indicator(-30℃ ~80℃ );

• No power calibration,range shrinking, factory value restoring available;

• Battery power supply available

Specifications

• Measure Range: 0bar~0.35bar…35bar

• Total Accuracy: ±0.25%FS

• Stability: ±0.2%FS/YEAR

• Compensated Temp.: -10℃ ~70℃

• Working Temp.: -30℃ ~80℃

• Storage Temp.: -40℃ ~85℃

• Power Supply: 8V~28V DC or Battery supply

• Output signal: Standard analog 4mA~20mA DC,2-wire; digital RS485 interface

• Battery supply with RS485 output: digital RS485 interface

• RS485 interface: ASCII agreement or MODBUS RTU, BUS with 99 transmitters

• Display Range: -19999~19999 LCD Display

• Housing: stainless steel

• Diaphragm stainless steel: 316L

• O-Ring: Viton

Image:

The MDM4760 Differential Pressure Transmitter is an advanced digital smart transmitter with special wide-temperature LCD display as well as digital compensation function, compact size, indicator can be rotated 90 degrees clockwise or anticlockwise to provide different interfaces, which not only measures and displays the differential pressure in a timely manner, but also facilitates the user's installation and use, which makes it an ideal choice for accurate measurement of flow pressure.

Features

• Optional data display(max.and min. measure value, percentage and output current display);

• Special wider temperature LCD indicator(-30℃ ~80℃ );

• No power calibration,range shrinking, factory value restoring available;

• Battery power supply available

Specifications

• Measure Range: 0bar~0.35bar…35bar

• Total Accuracy: ±0.25%FS

• Stability: ±0.2%FS/YEAR

• Compensated Temp.: -10℃ ~70℃

• Working Temp.: -30℃ ~80℃

• Storage Temp.: -40℃ ~85℃

• Power Supply: 8V~28V DC or Battery supply

• Output signal: Standard analog 4mA~20mA DC,2-wire; digital RS485 interface

• Battery supply with RS485 output: digital RS485 interface

• RS485 interface: ASCII agreement or MODBUS RTU, BUS with 99 transmitters

• Display Range: -19999~19999 LCD Display

• Housing: stainless steel

• Diaphragm stainless steel: 316L

• O-Ring: Viton

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.15%FS (Typ.)

RS485/HART Protocol

DNV approved for ship use

High-level electromagnetic compatibility

Support reverse polarity, transient overcurrent and over-voltage protection

LCD / LED display

CE approved

Diameter: DN25 ~ DN400

Nominal pressure: 0.6MPa/1.6MPa/4.0MPa

Lining material: Neoprene, Polyurethane Rubber, F4, F46

Electrode material: 316L, Ti, HB/HC, Ta, WC, Pt

Structure type: separated type, integrated type

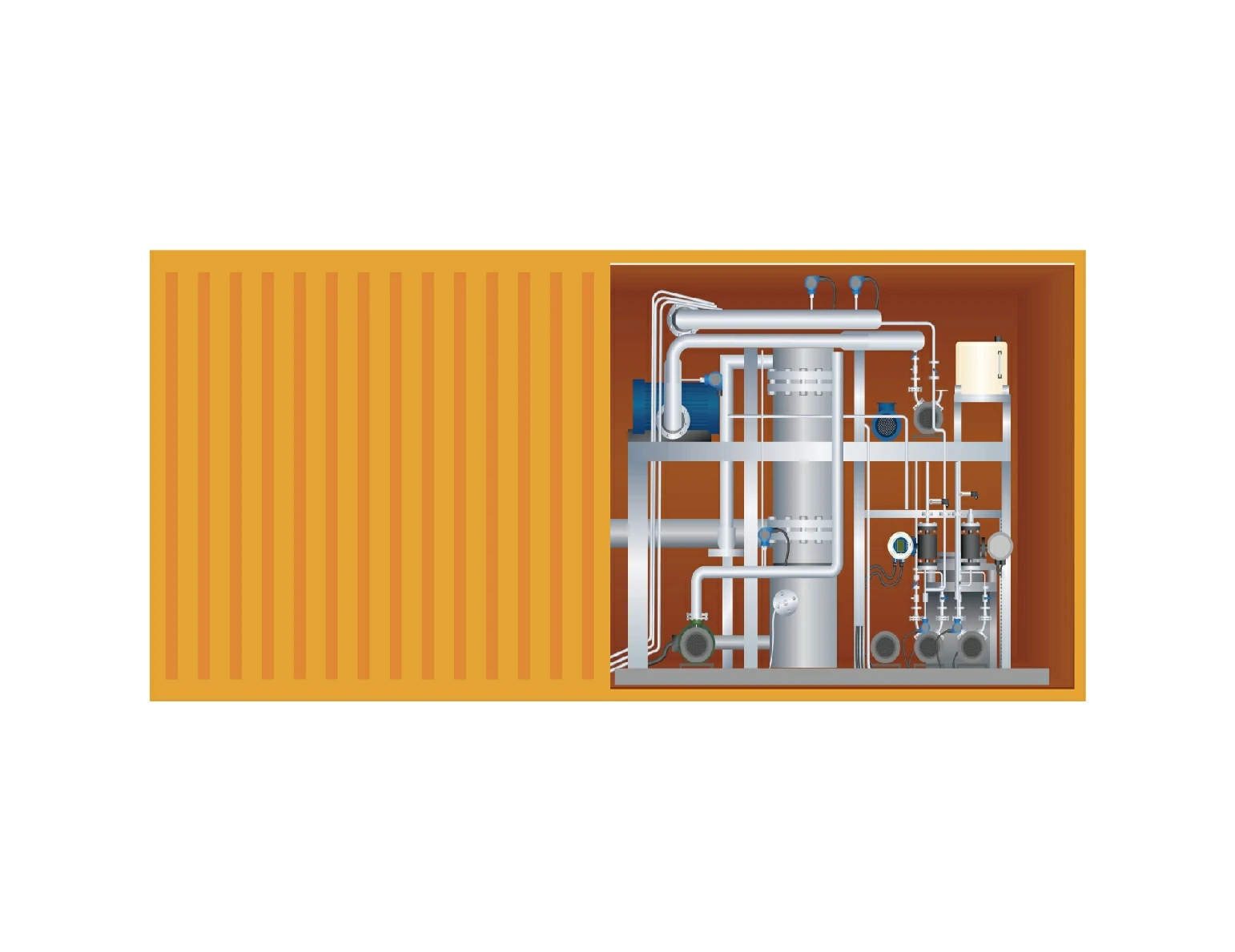

By monitoring the sewage flow, pipeline pressure and reservoir level, the efficiency of sewage treatment plant can be improved. At the same time, it can also facilitate operation and management, and achieve energy saving and automation control.

more info...

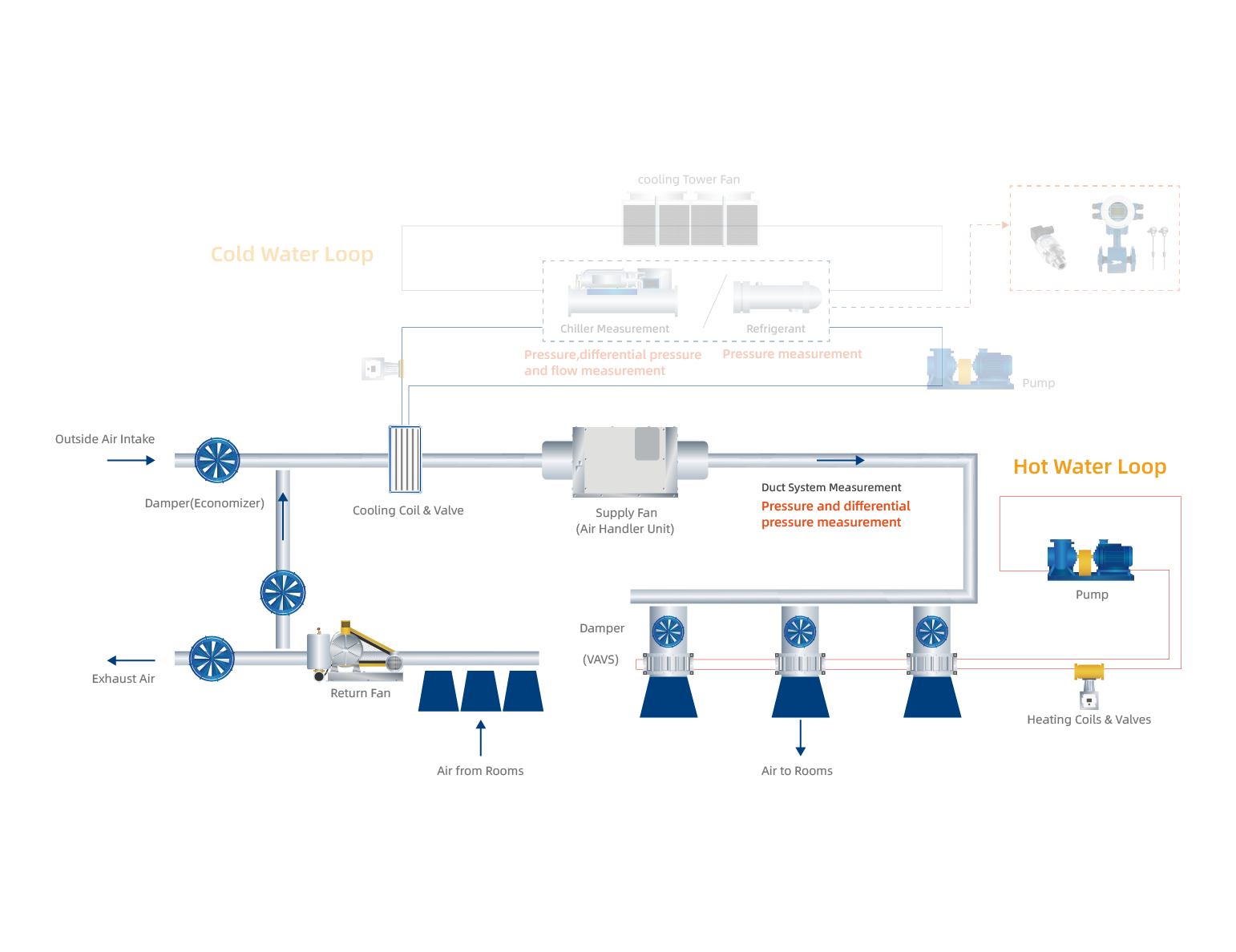

In HVAC duct systems, pressure measurement is crucial for maintaining optimal airflow. Pressure transmitters monitor air pressure to ensure efficient ventilation and proper air distribution. Accurate pressure data helps detect blockages, leaks, and maintain system balance, ensuring a comfortable and safe indoor environment.

more info...

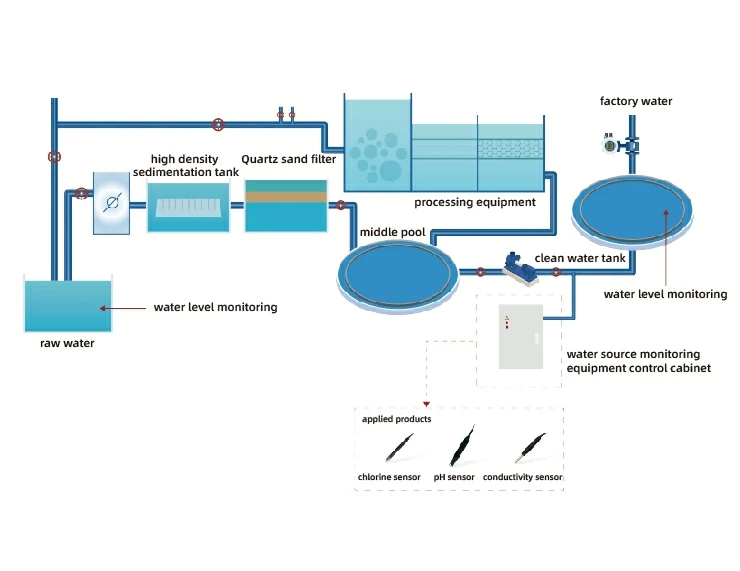

Pressure, flow, and level measuring instruments are deployed in water tanks, pipelines, and water inlets/outlets. This helps to manage the macro-control of production data in the water plant. Measuring instruments ensure smooth operation and normal production.

more info...

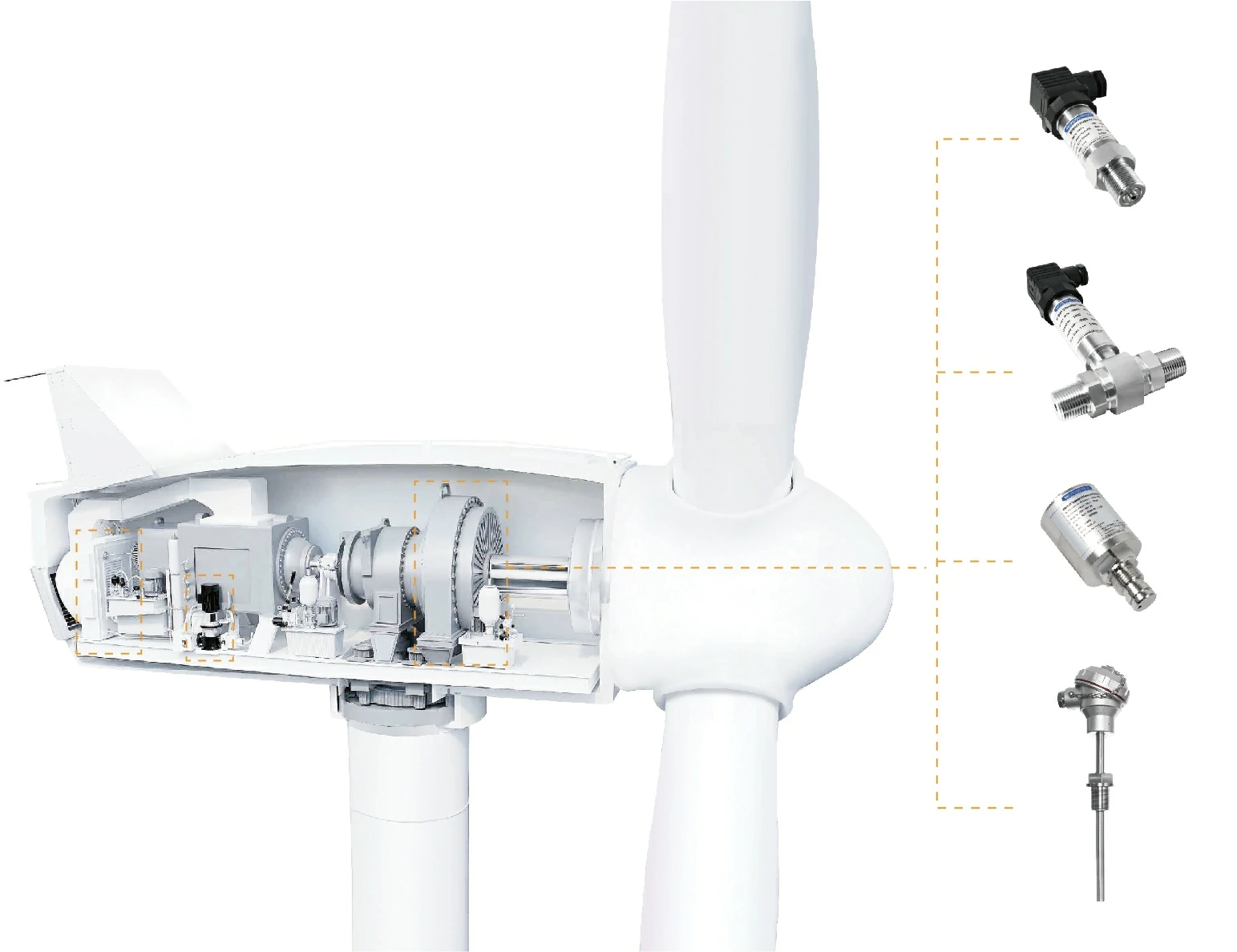

Wind turbine generators require a control system to optimize the direction of the turbine in accordance with the wind direction (yaw control) and adjust the angle of the blades (pitch control). This control system is completed by the cylinder system based on the hydraulic principle, in which the pressure sensor plays an important role.

more info...