Economical Pressure Transmitter

Range:0bar~250bar…600bar

Accuracy: ±0.5%FS

CE, RoHS

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM5581

Used For

Industrial Automation, Fire and Safety Systems, Hydraulic and Pneumatic Systems, Cooling Systems, Monitoring of Machinery and Equipment

Leave a MessageMPM5581 is a pressure switch that provides different types of output signals for various application scenarios. The liquid pressure switch measuring range is adjustable as 25%~100%FS. The MPM5581 pressure switch offers a wide range of functions, including time delay setting, and range drift setting, as well as features such as zeroing, base point, and peak value display. Its unique design and construction allow for diverse mounting. The product is equipped with a clear and easy-to-read OLED display.

Feature

• Various output configurations available for different applications

• The switch has a delay setting

• Provides manual clearing, base point, and peak display functions

• Display for visualization

Specifications

• Range: (bar) 1, 3.5, 7, 16, 35, 70,100, 250, 400, 600

• Pressure Type: Gauge, Absolute

• Accuracy: ±0.5%FS

• Hysteresis: ±0.2%FS

• Thermal error: ±0.02%FS/°C (Zero/FS)

• Long Time Stability: ±0.3%FS/year

• Outputs: 2 switches+current output: 2×PNP +0mA/4mA~20mADC

Image:

MPM5581 is a pressure switch that provides different types of output signals for various application scenarios. The liquid pressure switch measuring range is adjustable as 25%~100%FS. The MPM5581 pressure switch offers a wide range of functions, including time delay setting, and range drift setting, as well as features such as zeroing, base point, and peak value display. Its unique design and construction allow for diverse mounting. The product is equipped with a clear and easy-to-read OLED display.

Feature

• Various output configurations available for different applications

• The switch has a delay setting

• Provides manual clearing, base point, and peak display functions

• Display for visualization

Specifications

• Range: (bar) 1, 3.5, 7, 16, 35, 70,100, 250, 400, 600

• Pressure Type: Gauge, Absolute

• Accuracy: ±0.5%FS

• Hysteresis: ±0.2%FS

• Thermal error: ±0.02%FS/°C (Zero/FS)

• Long Time Stability: ±0.3%FS/year

• Outputs: 2 switches+current output: 2×PNP +0mA/4mA~20mADC

1, 2, 5, 10, 20, 50, 100, 200mH2O

Accuracy: ±0.25%FS (Typ.)

General Level Measurement

Widely used in the medical and pharmaceutical industry for oxygen measurement

All-welded design

Fully digital temperature compensation calibration

Adapted to breathable membranes

MDM7000-GP-T Accuracy:±0.1%、±0.2%URL

MDM7000-AP-T Accuracy:±0.1%、±0.2%URL

MDM7000-GP-T Range:0.4bar~100bar

MDM7000-AP-T Range:0.4bar~10bar

DNV, ABS, KR, NK, and RS approved for installation on vessels

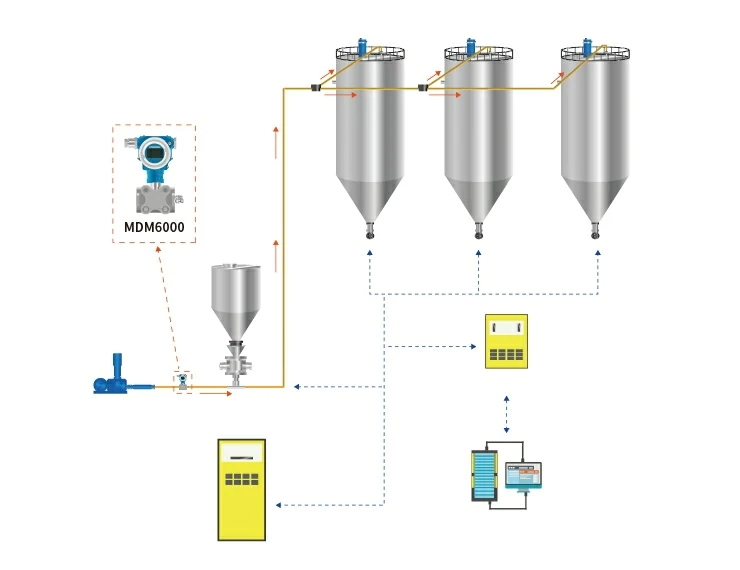

The production of positive and negative electrode materials for lithium cell requires the transmission of powdered materials. The sealed pipelines realize pneumatic transmission of solid powder or particles. However, blockages can occur in the container when conveying materials with large particle sizes, high viscosity, or poor flow ability. Installed pressure transmitters solve this problem. An abnormal pressure alarm will be triggered to identify the location. This facilitates timely repair of the blockage, ensuring normal production and operation.

more info...

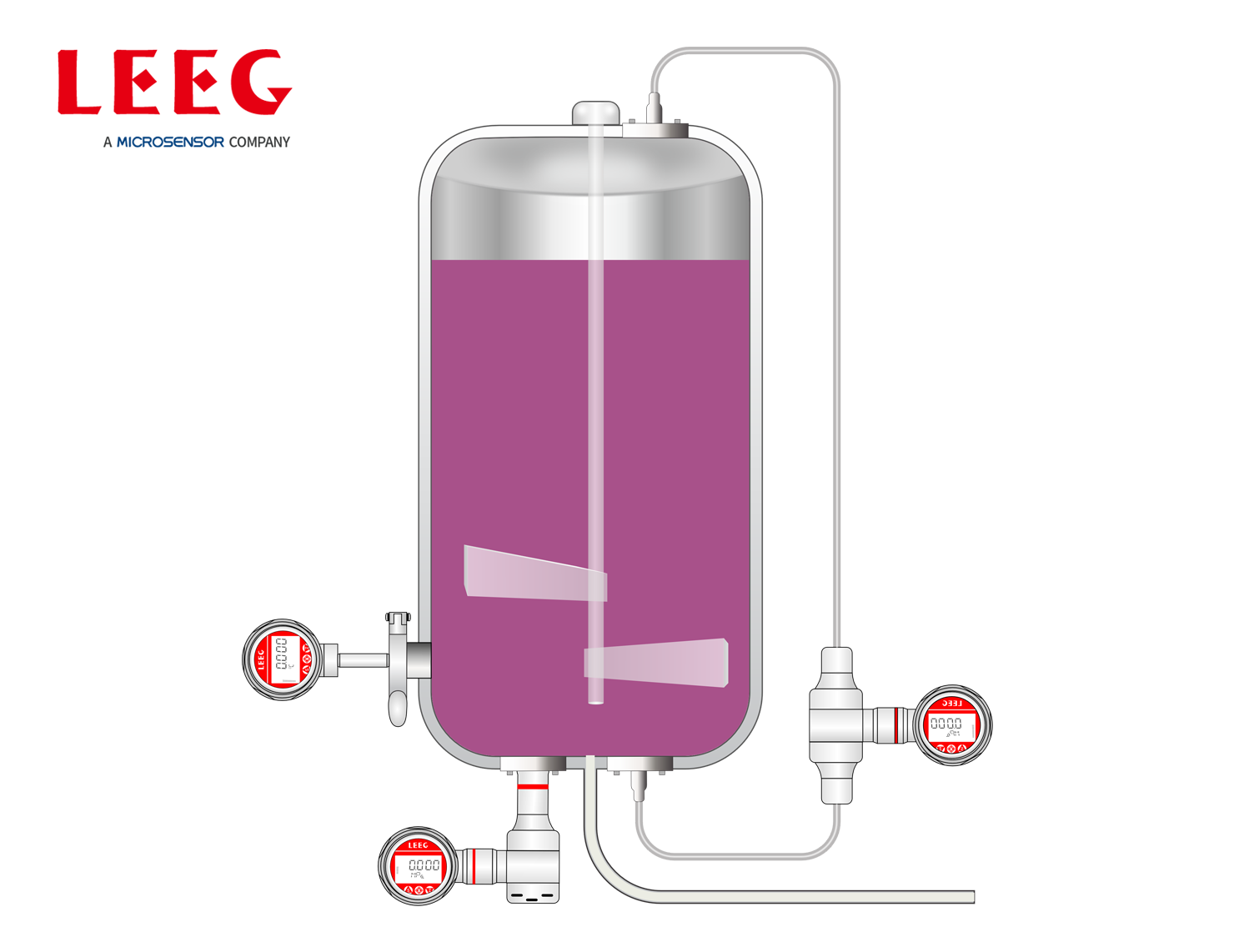

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...

In beverage storage tanks, the role of the liquid level transmitter is to monitor the material inventory in real time by measuring the liquid level height of milk or beverages in the tank; the temperature transmitter measures the temperature of the material in the tank to ensure that it is within the appropriate storage and processing temperature range, preventing deterioration due to excessively high temperature or affecting the taste of the product due to excessively low temperature.

more info...

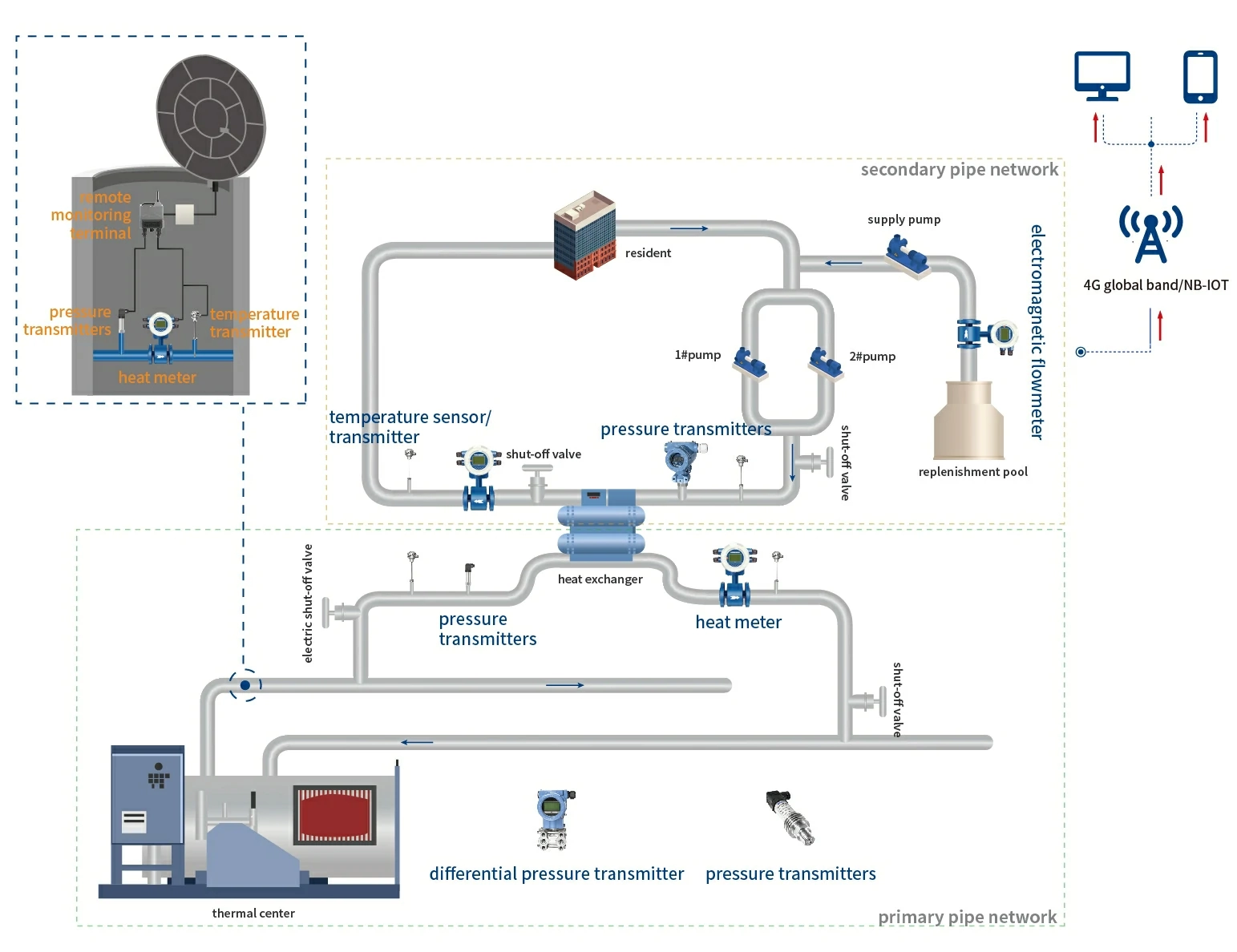

Electromagnetic flowmeters, ultrasonic flowmeters, level transmitters, pressure transmitters are installed in the heat exchange station heating system to obtain real-time data on pipeline flow, heat, temperature, and pressure, ensuring the normal operation of the heat exchange station.

more info...