Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4706

Used For

Underground Water Conservancy, Hydrology, Water Resources, Petroleum and Petrochemical

Leave a MessageMPM4706 digital level transmitter enables liquid level and temperature measurement, which communicates based on the RS485 interface. The level sensor has high precision, and automatic sleep mode. Power consumption as low as 10uA. It can be applied in various digital fields, and can ensure the high-efficiency and low-cost operation of the application system while performing precise measurements. MPM4706 liquid level sensor is applied to groundwater, hydrology, water conservancy, petroleum and petrochemical, coal, etc.

Features

• Level & Temperature Measurement

• Suitable for various digital application sites

• Average working current≤3mA, standby power consumption≤10uA

• Liquid level accuracy: ±0.25%

• Temperature accuracy: ±0.5°C

Specification

• Measured range: 0~3.5...200 mH2O

• Over pressure: 1.5 × FS

• Total accuracy: ±0.25%FS(-10℃~70℃)

• Temperature accuracy: ±0.5℃(20℃~80℃), ±0.75℃(-30℃~-20℃)

• Output: RS485

• Compensation temperature: -10℃~ 70℃

• Operation temperature: -10℃~ 70℃

• Long-term stability: ±0.25%FS/year

• Load: RS485 terminal can cascade up to 99 transmitters

Image:

MPM4706 digital level transmitter enables liquid level and temperature measurement, which communicates based on the RS485 interface. The level sensor has high precision, and automatic sleep mode. Power consumption as low as 10uA. It can be applied in various digital fields, and can ensure the high-efficiency and low-cost operation of the application system while performing precise measurements. MPM4706 liquid level sensor is applied to groundwater, hydrology, water conservancy, petroleum and petrochemical, coal, etc.

Features

• Level & Temperature Measurement

• Suitable for various digital application sites

• Average working current≤3mA, standby power consumption≤10uA

• Liquid level accuracy: ±0.25%

• Temperature accuracy: ±0.5°C

Specification

• Measured range: 0~3.5...200 mH2O

• Over pressure: 1.5 × FS

• Total accuracy: ±0.25%FS(-10℃~70℃)

• Temperature accuracy: ±0.5℃(20℃~80℃), ±0.75℃(-30℃~-20℃)

• Output: RS485

• Compensation temperature: -10℃~ 70℃

• Operation temperature: -10℃~ 70℃

• Long-term stability: ±0.25%FS/year

• Load: RS485 terminal can cascade up to 99 transmitters

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

Using shear and agitation to evenly distribute the fibers, the pulp tank in the papermaking process combines pulp and water. Following mixing, shearing, and temperature control, the processed slurry is released to feed the machinery used in the papermaking process downstream. The slurry can only enter the headbox for the subsequent step if the level is measured accurately.

more info...

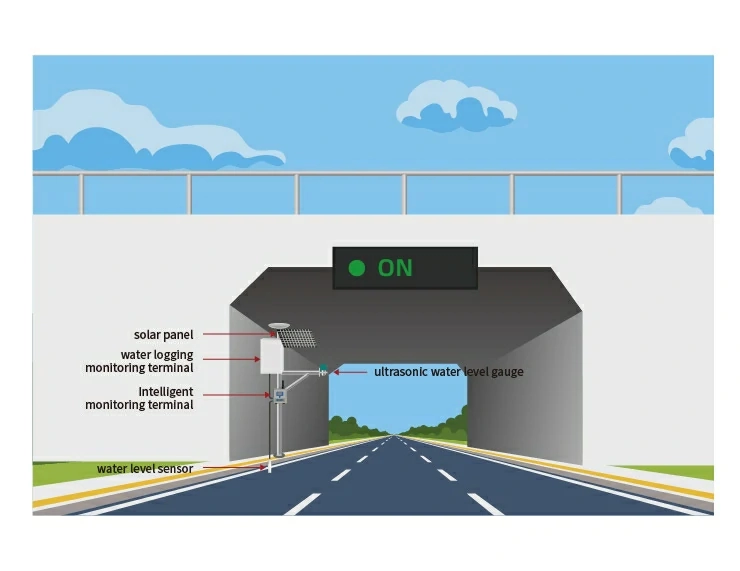

Real-time monitoring the low-ling areas, underpasses and bridge culverts. The current level and alarming messages are automatically displayed on the screen, such as “Passage”, “Allowing”, and “No entering”. The alarm will be triggered when the level is too high, aiming to ensure the personnel's safety.

more info...

The pulp undergoes high-temperature bleaching in a tower using peroxides, ozone, or oxygen to get the right white color. The tower usually stays empty while the large amount of bleached pulp is dumped via a screw conveyor.

more info...

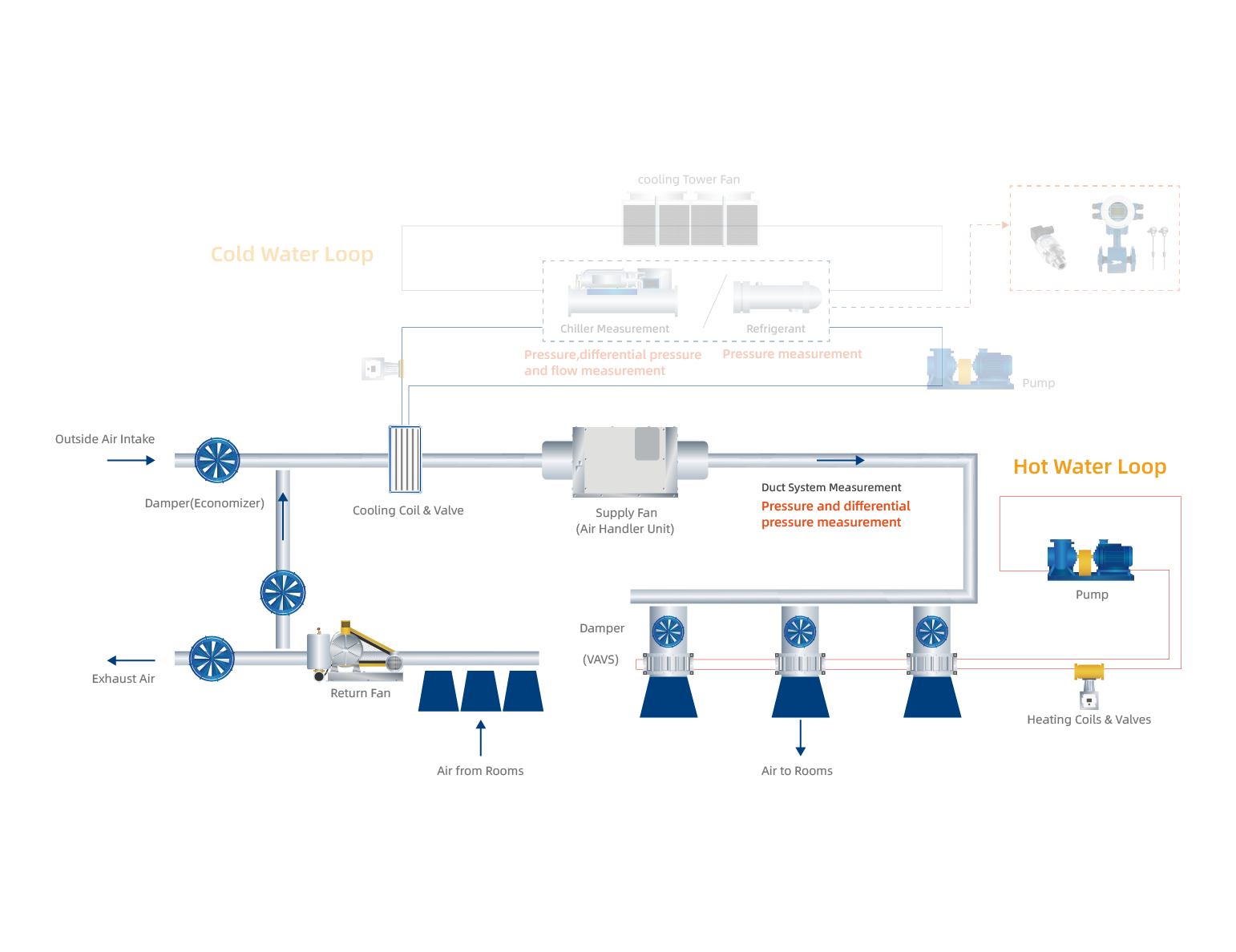

In HVAC duct systems, pressure measurement is crucial for maintaining optimal airflow. Pressure transmitters monitor air pressure to ensure efficient ventilation and proper air distribution. Accurate pressure data helps detect blockages, leaks, and maintain system balance, ensuring a comfortable and safe indoor environment.

more info...