Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM4811

Used For

Petroleum Industry, Chemical Engineering, Power Plant, Urban Water Supply and Drainage

Leave a MessageMPM4811 IP68 Submersible Level Transmitter adopts stainless steel housing with good sealing, which can be used in liquid environment. Installed with high accuracy and high stability pressure sensor and reliable signal processing circuit, with temperature and liquid level dual output function. Measuring range is liquid level to 200mH2O depth, temperature range is -20 to 70C. support 4~20mA dual output, with level and temperature dual standard output.

Features

• Reversed-polarity protection

• Automatic production line for quality guarantee, stable and reliable

Specifications

• Range: 0mH2O ~ 1mH2O…200mH2O, -20℃ ...0℃ ~ 10℃ ...70℃

• Overpressure: ≤2 times FS

• Pressure Type: gauge, absolute

• Accuracy: ±1%FS (0mH2O ~ 1mH2O < X < 2mH2O), ±0.5%FS (2mH2O ≤ X < 200mH2O)

Image:

MPM4811 IP68 Submersible Level Transmitter adopts stainless steel housing with good sealing, which can be used in liquid environment. Installed with high accuracy and high stability pressure sensor and reliable signal processing circuit, with temperature and liquid level dual output function. Measuring range is liquid level to 200mH2O depth, temperature range is -20 to 70C. support 4~20mA dual output, with level and temperature dual standard output.

Features

• Reversed-polarity protection

• Automatic production line for quality guarantee, stable and reliable

Specifications

• Range: 0mH2O ~ 1mH2O…200mH2O, -20℃ ...0℃ ~ 10℃ ...70℃

• Overpressure: ≤2 times FS

• Pressure Type: gauge, absolute

• Accuracy: ±1%FS (0mH2O ~ 1mH2O < X < 2mH2O), ±0.5%FS (2mH2O ≤ X < 200mH2O)

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

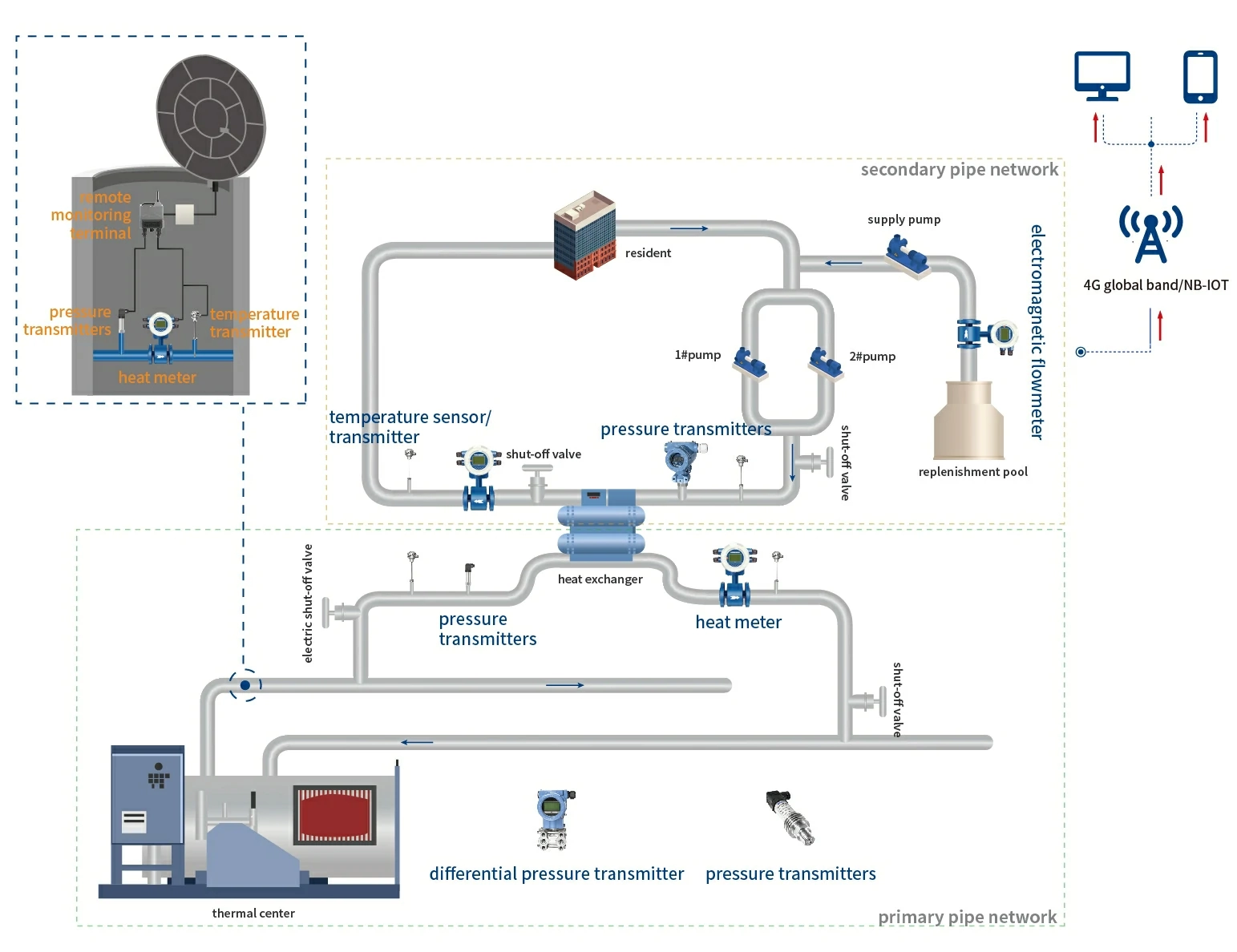

Electromagnetic flowmeters, ultrasonic flowmeters, level transmitters, pressure transmitters are installed in the heat exchange station heating system to obtain real-time data on pipeline flow, heat, temperature, and pressure, ensuring the normal operation of the heat exchange station.

more info...

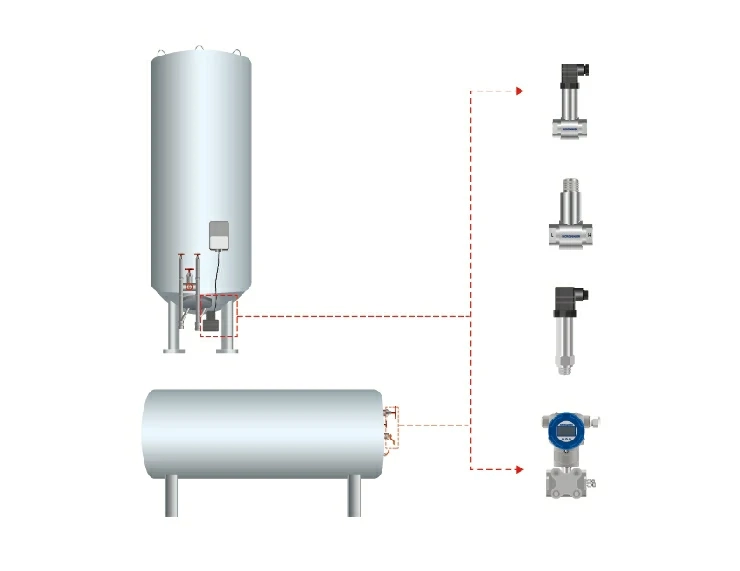

Pressure transmitters are used not only to measure the pressure inside the tank but also to measure the absolute pressure of the tank body and the pressure before and after the cryogenic pump, ensuring the safe operation of the system. Differential pressure measurement is the most common and reliable method for measuring the liquid level of cryogenic high-pressure bulk storage tanks.

more info...

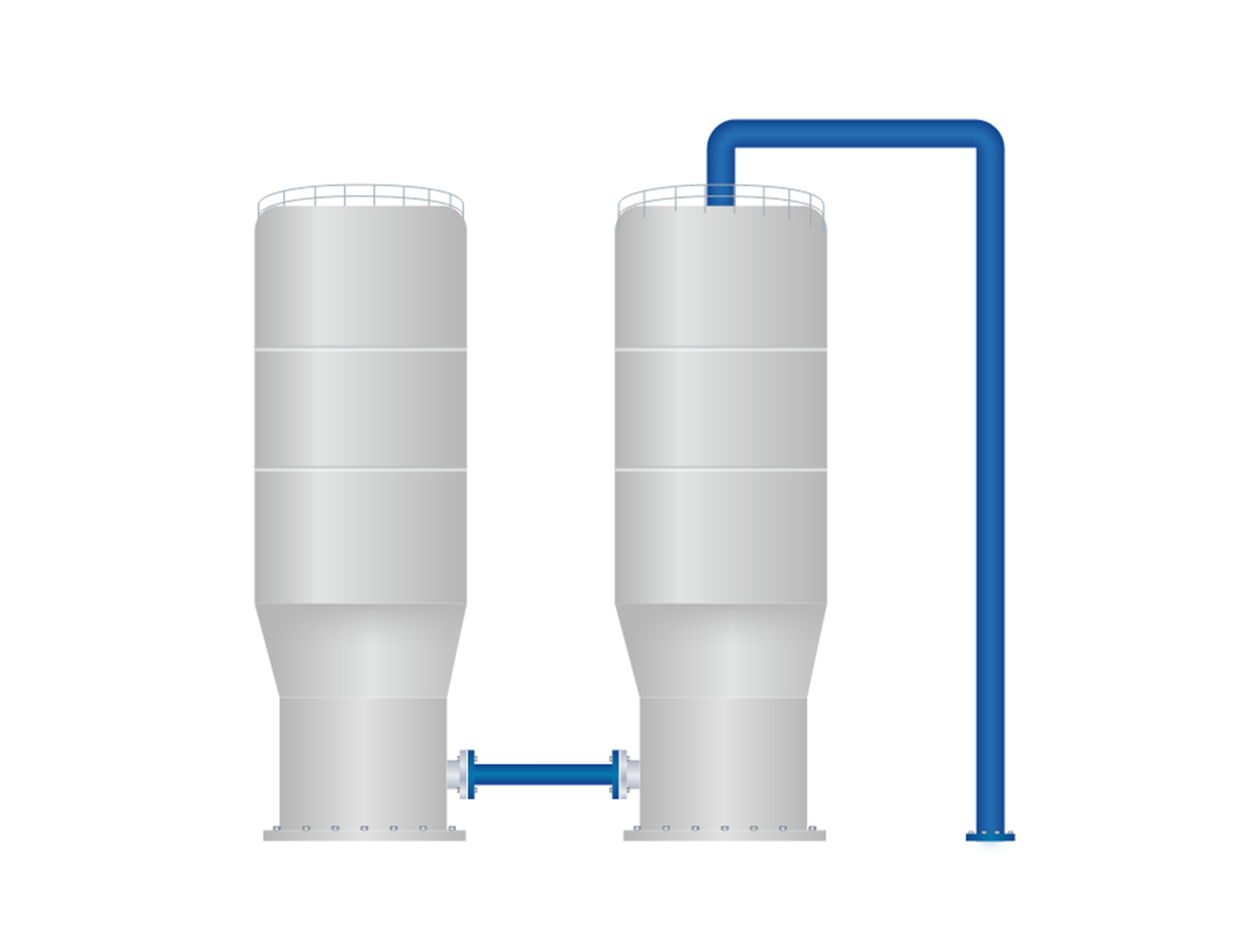

Large, high-capacity pulp storage towers with agitation homogenize the prepared pulp to guarantee continuous paper mill operation. Pump operation produces steam from the heated, agitated pulp, which also causes level oscillations.

more info...

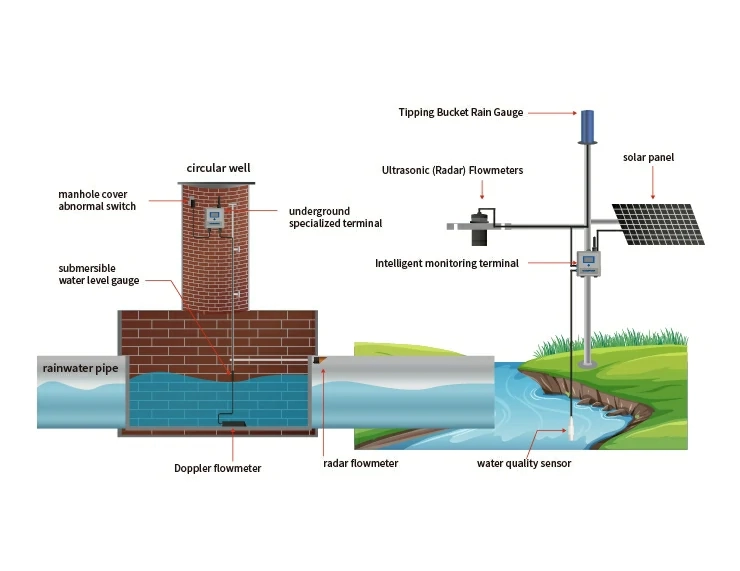

Pressure, level, and flow measurements at the rainwater outlet ensure stable drainage. Monitoring instruments help detection and early warning of pipe burst incidents in time.

more info...