Differential Pressure Transmitter

Output: mV

Accuracy: 0.25%FS

Max. static pressure 20MPa

MFE600

Used For

The MFE600 electromagnetic flowmeter is suitable for flow measurement of conductive liquids like wasted water etc. It has a flange type fitting, DN10 to DN1400, for use in petroleum, chemical, metallurgy, water supply, and drainage.

Leave a MessageMFE600 intelligent electromagnetic flowmeter is a volume flux measurement instrument. Ranging from DN6 to DN1400, the electromagnetic flow meter is CE marked, outputs analog 4mA ~ 20mA DC and digital HART, RS485. MicroSensor has a 35m high water tower as a voltage regulator for actual flow calibration. Professional electromagnetic flowmeter production lines ensure mass production and long-term high quality.

Image:

MFE600 intelligent electromagnetic flowmeter is a volume flux measurement instrument. Ranging from DN6 to DN1400, the electromagnetic flow meter is CE marked, outputs analog 4mA ~ 20mA DC and digital HART, RS485. MicroSensor has a 35m high water tower as a voltage regulator for actual flow calibration. Professional electromagnetic flowmeter production lines ensure mass production and long-term high quality.

Volume flux measurement

RS485/RS232 communication protocol

MDM7000-GP-T Accuracy:±0.1%、±0.2% URL

MDM7000-AP-T Accuracy:±0.1%、±0.2% URL

MDM7000-GP-T Range:0.4bar~100bar

MDM7000-AP-T Range:0.4bar~10bar

DNV, ABS, KR, NK, and RS approved for installation on vessels

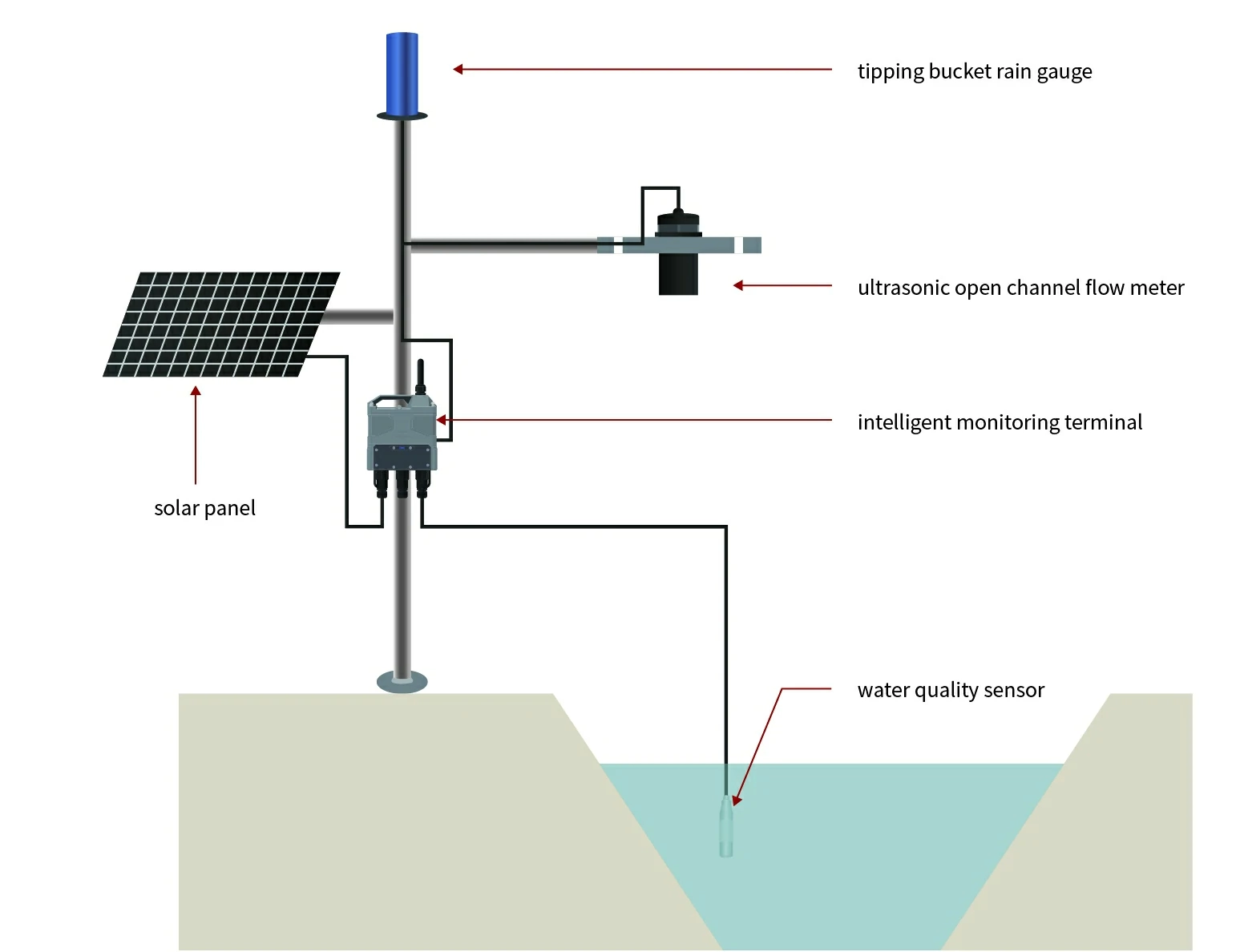

Monitor level and flow data within the river channel. Issue a warning when the water level is about to exceed the river warning line. Additionally, water quality sensor can be installed to report data such as pH value and turbidity to the relevant department's monitoring center when these values exceed normal levels. This monitors water quality, protects the river water environments, and provides data support for the supervision of illegal discharge and leakage.

more info...

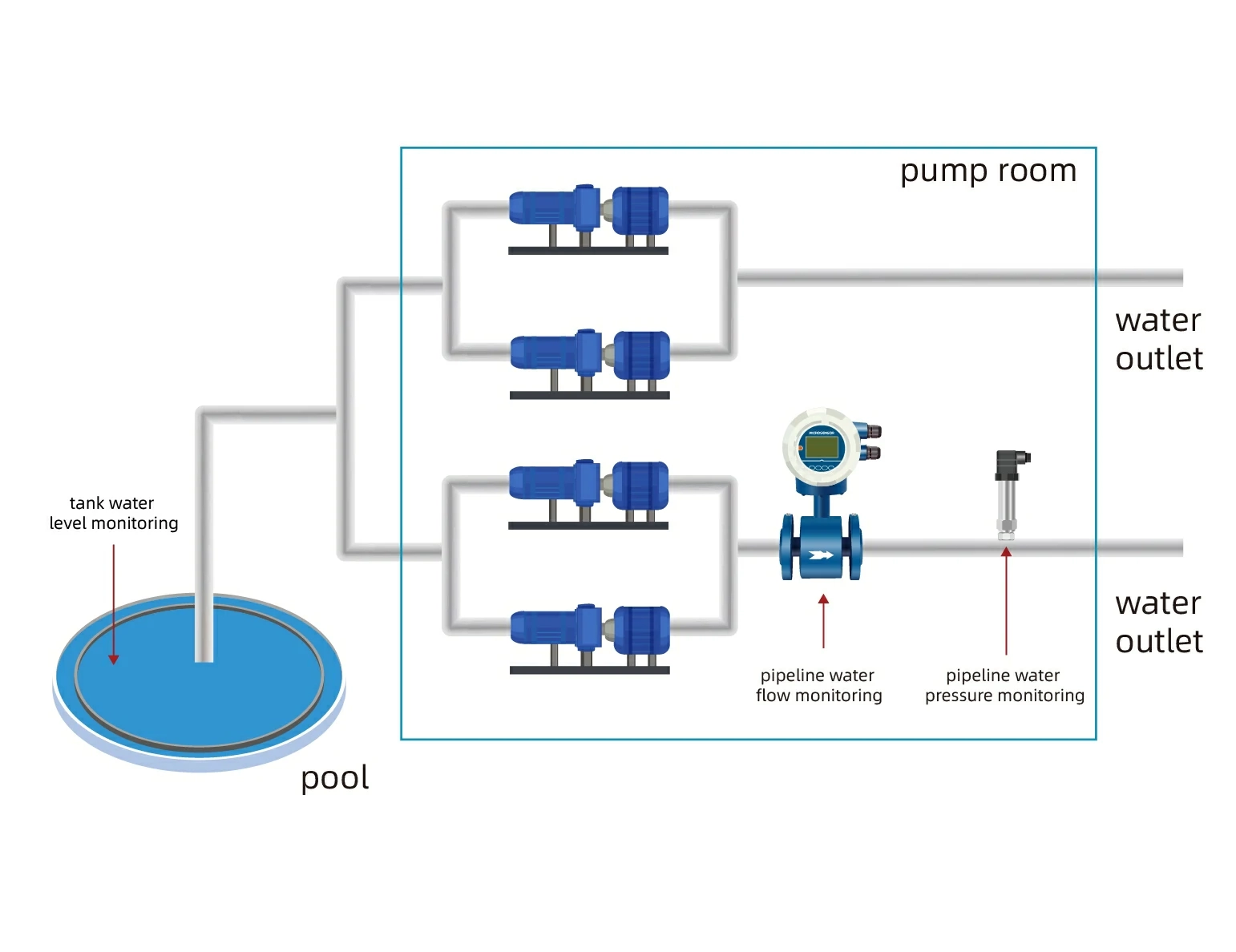

Water storage tank level, pipeline pressure, and flow within the pumping station can transmit status data to the platform via wireless networks. When anomalies are detected, the platform timely alarms. The staff handles fault information immediately. It ensures the normal operation of the water supply system.

more info...

Pressure transmitters, level transmitters, and mass flow meters are installed in fuel tanks to provide real-time monitoring of fuel levels and pressure. Users can track current location and fuel consumption, access historical vessel data, calculate voyage distance and total fuel usage, and analyze operational efficiency.

more info...

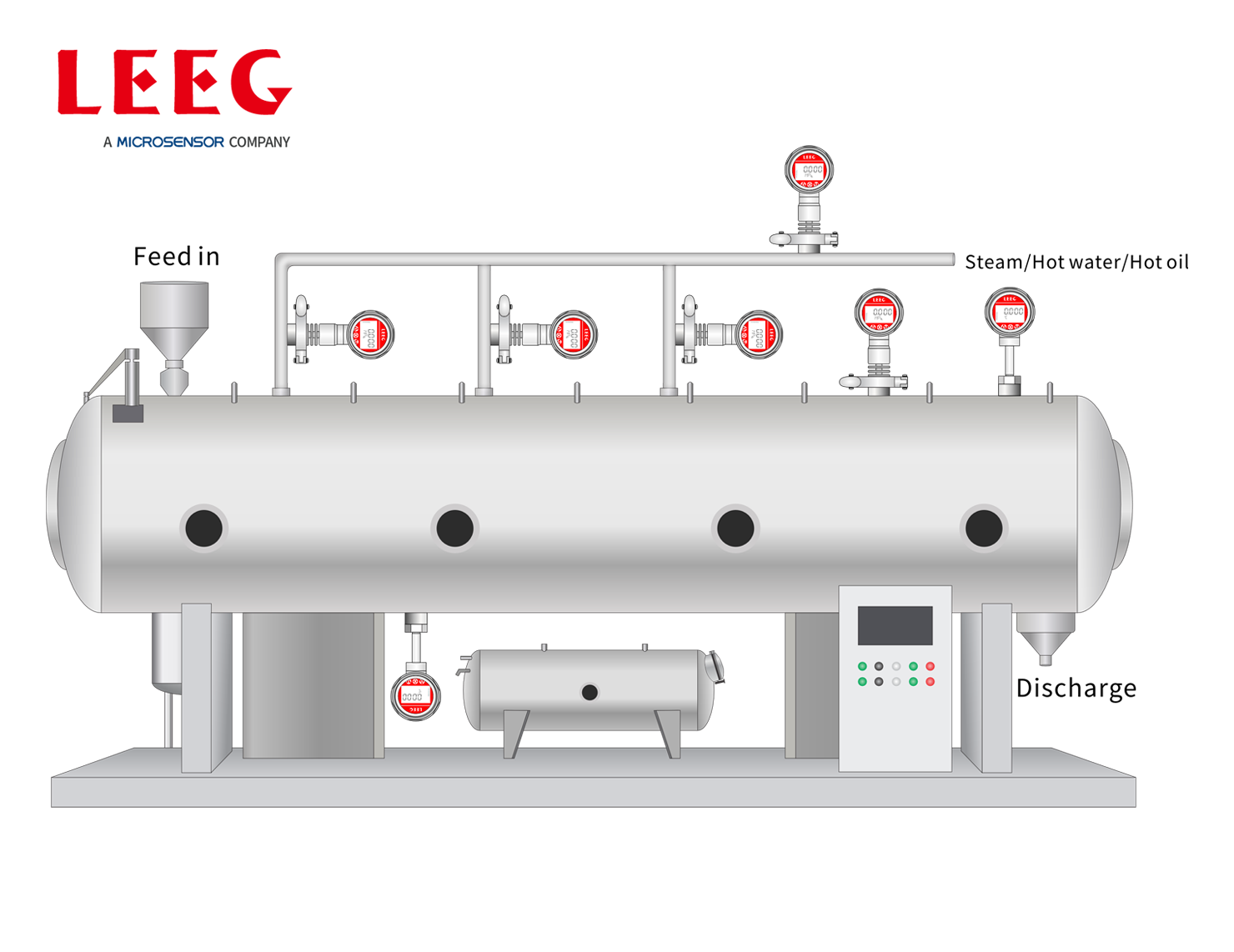

Dryers are often used to dry medicines or extract active ingredients from traditional Chinese medicines, which are easily decomposed in high temperature environments. Temperature measurement is required in the heating area, cooling area and material outlet of the dryer, and pressure transmitters are used to measure the pressure of air or gas to help adjust the air flow speed and fan operation status, or measure the pressure of steam, hot water, and hot oil pipelines.

more info...