Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

MPM316W

Used For

Measurement Fluid Level of Drinking Water, Underground Water, Seawater, Lake and Water Tanks

Leave a MessageThe MPM316W submersible level sensor is the perfect solution for measuring and monitoring of level. The air guide tube inside the cable connects the sensor back pressure cavity with the atmosphere at the cable outlet, which ensures the accuracy of the measurement. It is zero and full span temperature compensated under -10℃ ~70℃, guaranteeing use in different temperature environments. The sealed structure and IP68 protection feature are to be submerged underwater for long-term measurement and to ensure a long life. The Level sensor can be applied to water treatment, water, or oil tanks.

Features

• Piezoresistive pressure sensor

• Throw-in type with IP68 protection

• Constant current supply

• Compensation test process

Specification

• Pressure range: 0~1m…200m H2O

• Overpressure: 1.5 times FS

• Power supply: 1.5mADC

• Zero output: <±2mVDC

• FS output: ≥70mVDC or ≥25mVDC(range<2mH2O)

• Accuracy: ±0.1%FS(min.), ±0.25%FS(typ.), ±0.5%FS(max.)

• Long-term stability: ±0.3%FS/year

• Compensation temp.: 0℃ ~50℃

• Operation temp.: -10℃ ~70℃

Image:

The MPM316W submersible level sensor is the perfect solution for measuring and monitoring of level. The air guide tube inside the cable connects the sensor back pressure cavity with the atmosphere at the cable outlet, which ensures the accuracy of the measurement. It is zero and full span temperature compensated under -10℃ ~70℃, guaranteeing use in different temperature environments. The sealed structure and IP68 protection feature are to be submerged underwater for long-term measurement and to ensure a long life. The Level sensor can be applied to water treatment, water, or oil tanks.

Features

• Piezoresistive pressure sensor

• Throw-in type with IP68 protection

• Constant current supply

• Compensation test process

Specification

• Pressure range: 0~1m…200m H2O

• Overpressure: 1.5 times FS

• Power supply: 1.5mADC

• Zero output: <±2mVDC

• FS output: ≥70mVDC or ≥25mVDC(range<2mH2O)

• Accuracy: ±0.1%FS(min.), ±0.25%FS(typ.), ±0.5%FS(max.)

• Long-term stability: ±0.3%FS/year

• Compensation temp.: 0℃ ~50℃

• Operation temp.: -10℃ ~70℃

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

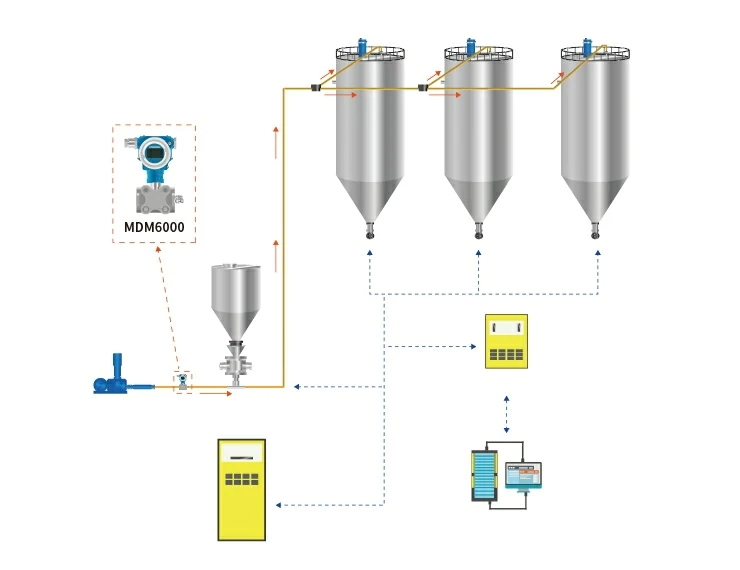

The production of positive and negative electrode materials for lithium cell requires the transmission of powdered materials. The sealed pipelines realize pneumatic transmission of solid powder or particles. However, blockages can occur in the container when conveying materials with large particle sizes, high viscosity, or poor flow ability. Installed pressure transmitters solve this problem. An abnormal pressure alarm will be triggered to identify the location. This facilitates timely repair of the blockage, ensuring normal production and operation.

more info...

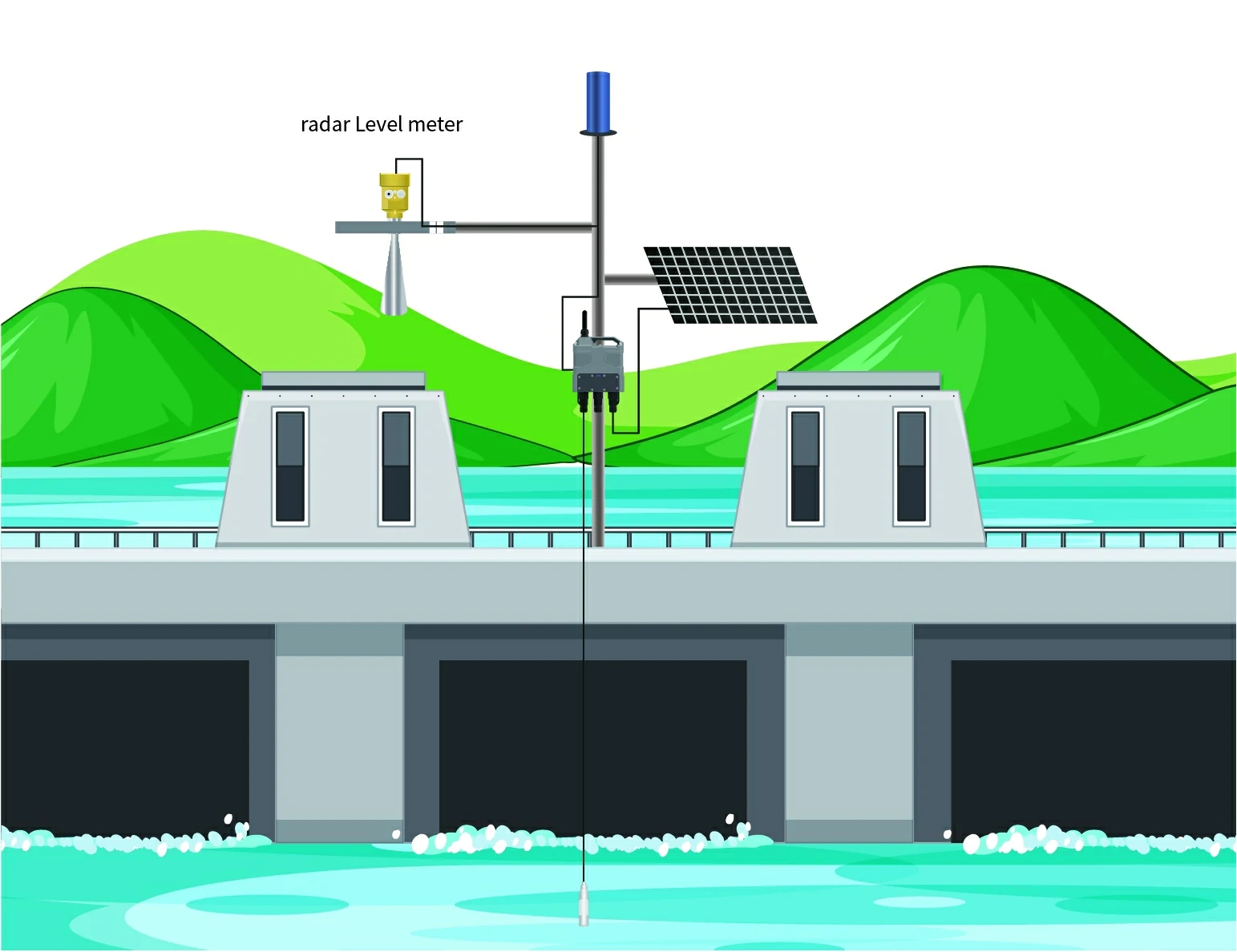

Real-time collection of reservoir water level, rainfall, and other information at dam monitoring points. Based on the changes in water level and the maximum capacity of the dam, calculations are made, and warnings and alarms are issued when the water level rises above the alert value.

more info...

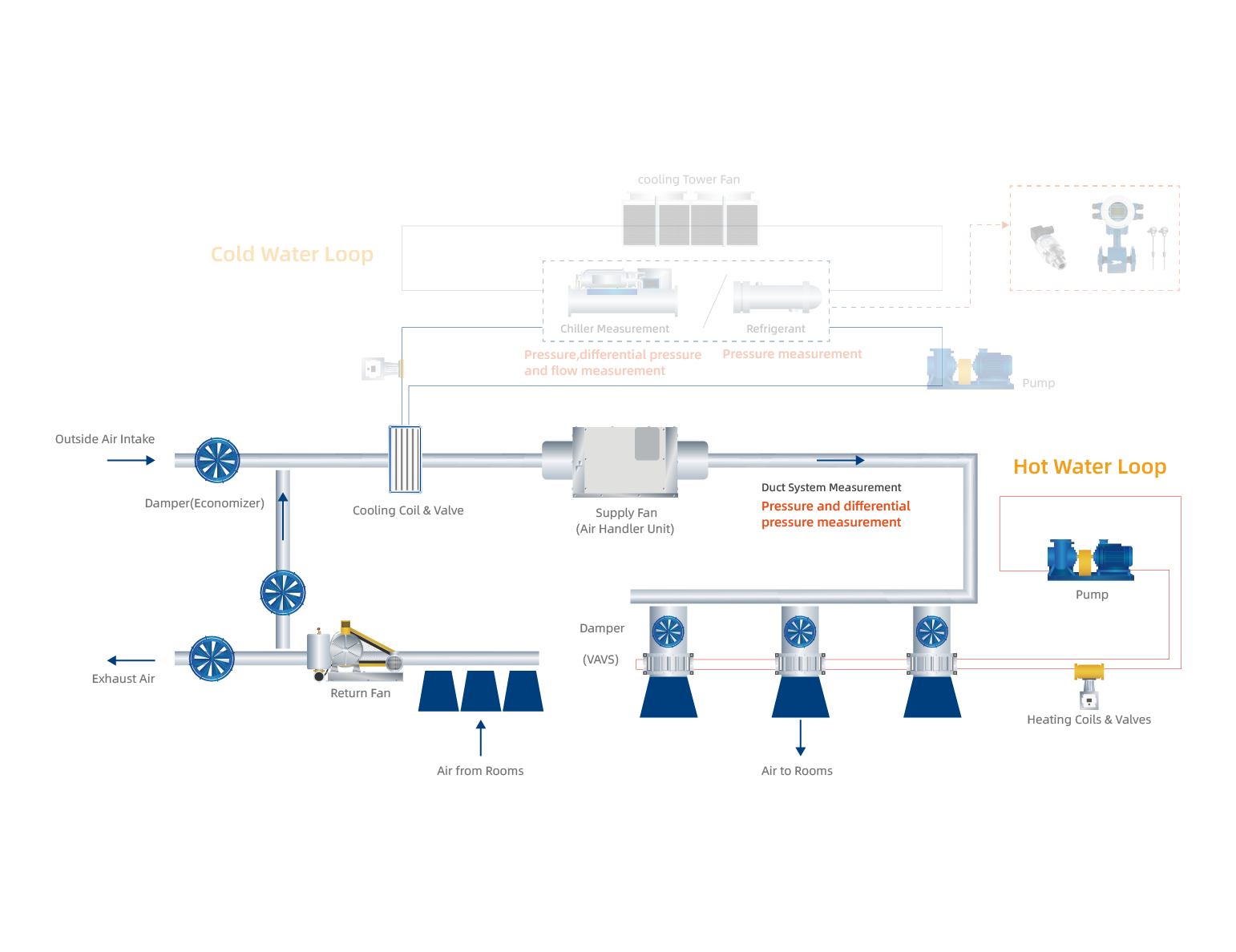

In HVAC duct systems, pressure measurement is crucial for maintaining optimal airflow. Pressure transmitters monitor air pressure to ensure efficient ventilation and proper air distribution. Accurate pressure data helps detect blockages, leaks, and maintain system balance, ensuring a comfortable and safe indoor environment.

more info...

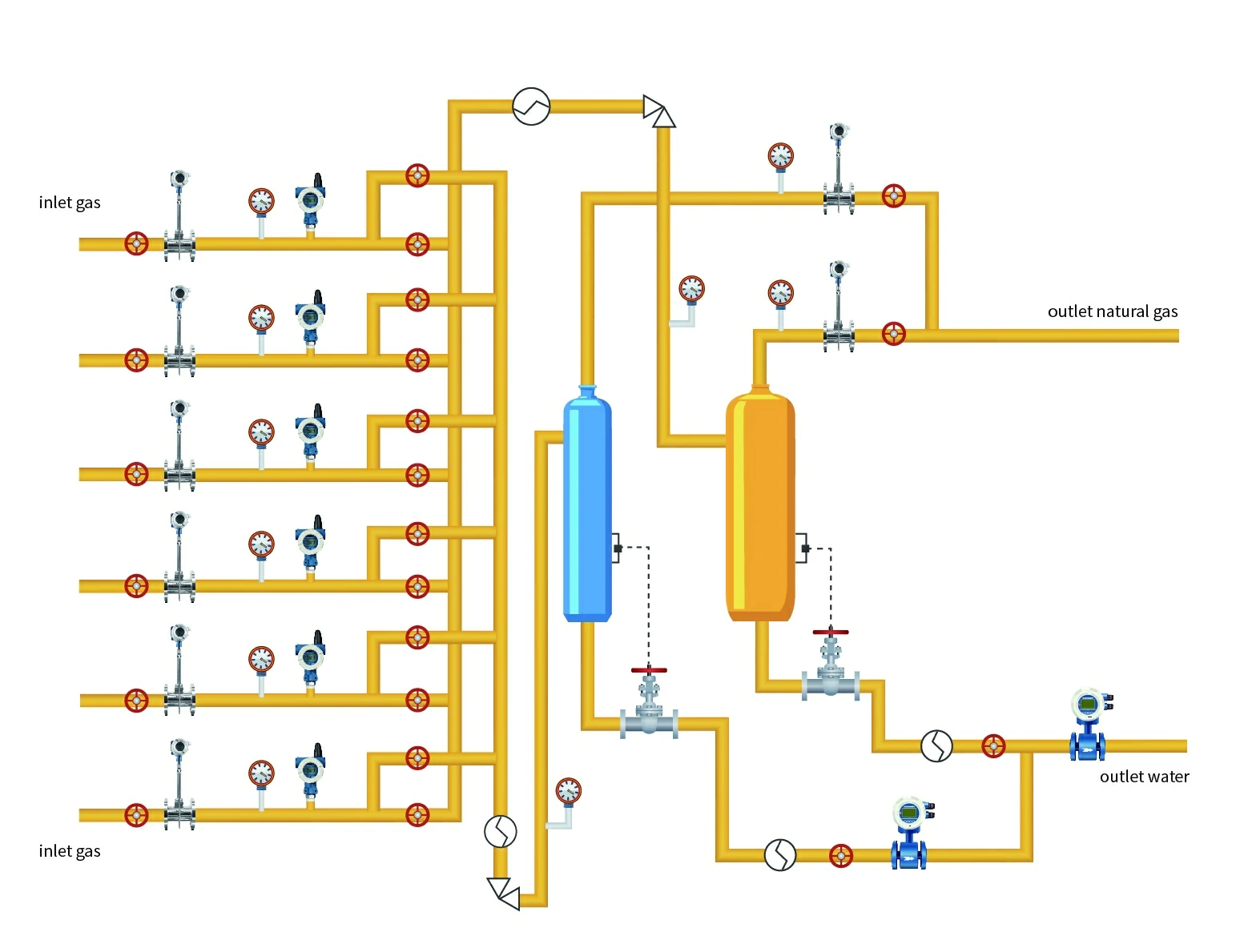

Gas gathering stations gather and process natural gas from multiple wells. Instruments in the pipeline monitor real-time data changes, such as gas or liquid flow. It helps control the water injection for the purpose of measuring and transporting oil and gas.

more info...