Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MLM

Used For

For large storage tank level measurement with high range

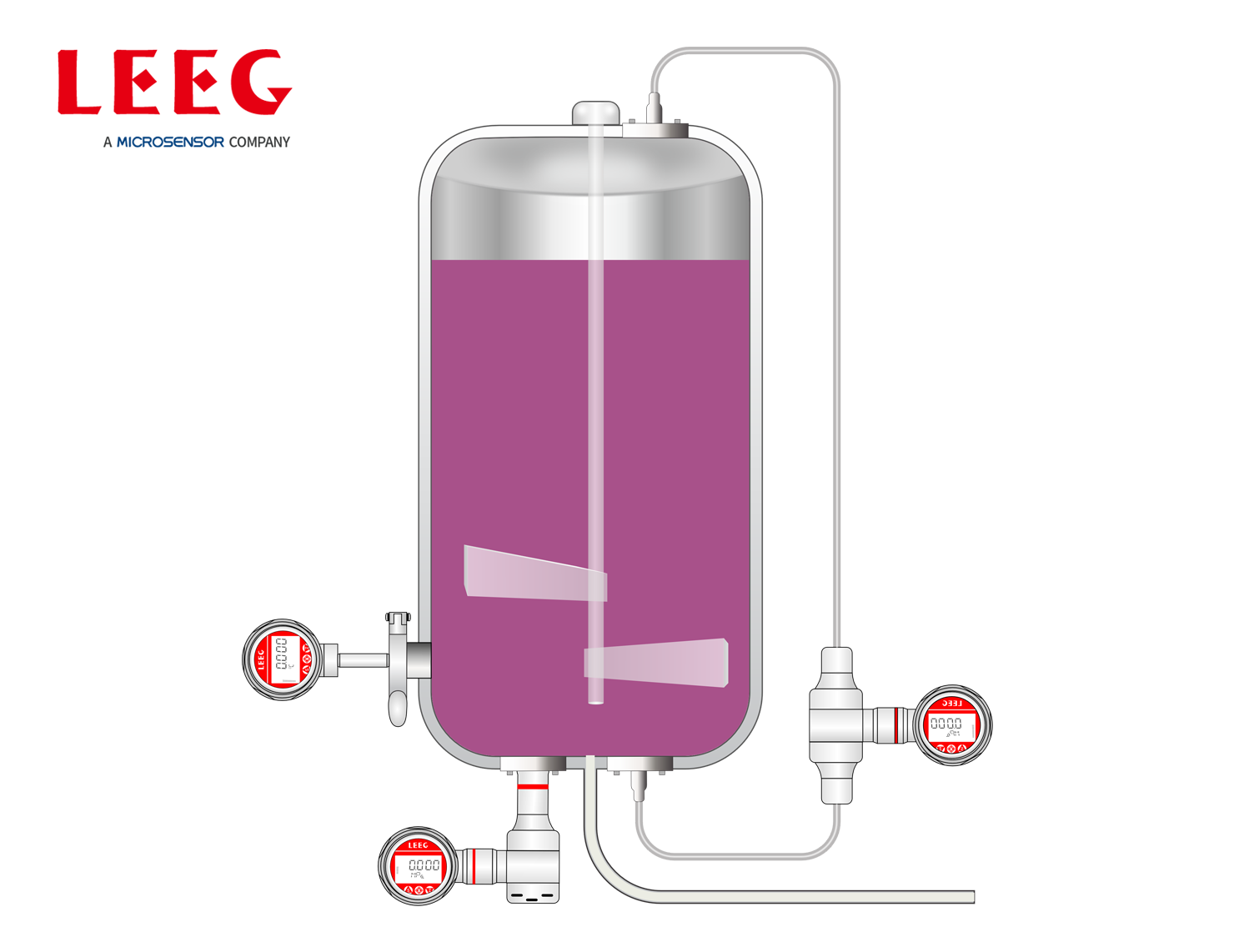

Leave a MessageFeatured with high accuracy and stability, the new generation of MLM series magnetostrictive level transmitter can measure the level at multiple positions and temperature points simultaneously.

With strong anti-pollution ability, it is suitable for harsh industrial environments. It can be widely used in the liquid level measurement and controlof various liquids tanks in the area of petroleum, hydraulics, pharmaceutical, food,beverage.

Image:

Featured with high accuracy and stability, the new generation of MLM series magnetostrictive level transmitter can measure the level at multiple positions and temperature points simultaneously.

With strong anti-pollution ability, it is suitable for harsh industrial environments. It can be widely used in the liquid level measurement and controlof various liquids tanks in the area of petroleum, hydraulics, pharmaceutical, food,beverage.

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

In beverage storage tanks, the role of the liquid level transmitter is to monitor the material inventory in real time by measuring the liquid level height of milk or beverages in the tank; the temperature transmitter measures the temperature of the material in the tank to ensure that it is within the appropriate storage and processing temperature range, preventing deterioration due to excessively high temperature or affecting the taste of the product due to excessively low temperature.

more info...

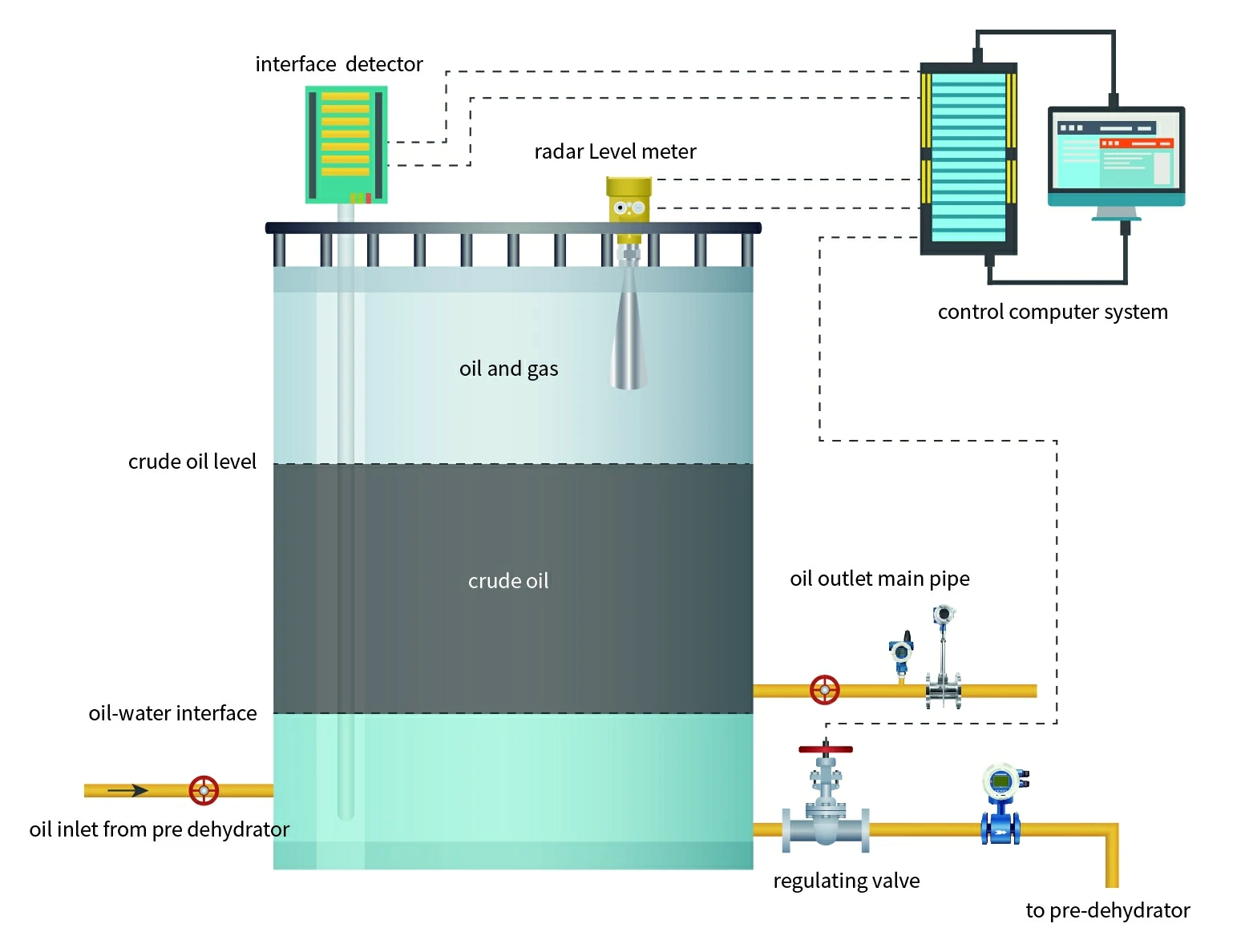

There are a large number of application scenarios of oil, gas, water and other fluid medias in industrial production, which are often stored in tanks of various sizes. Instruments can be installed to monitor the liquid level and pressure changes in the tanks, and automation management can be achieved through platforms and networks.

more info...

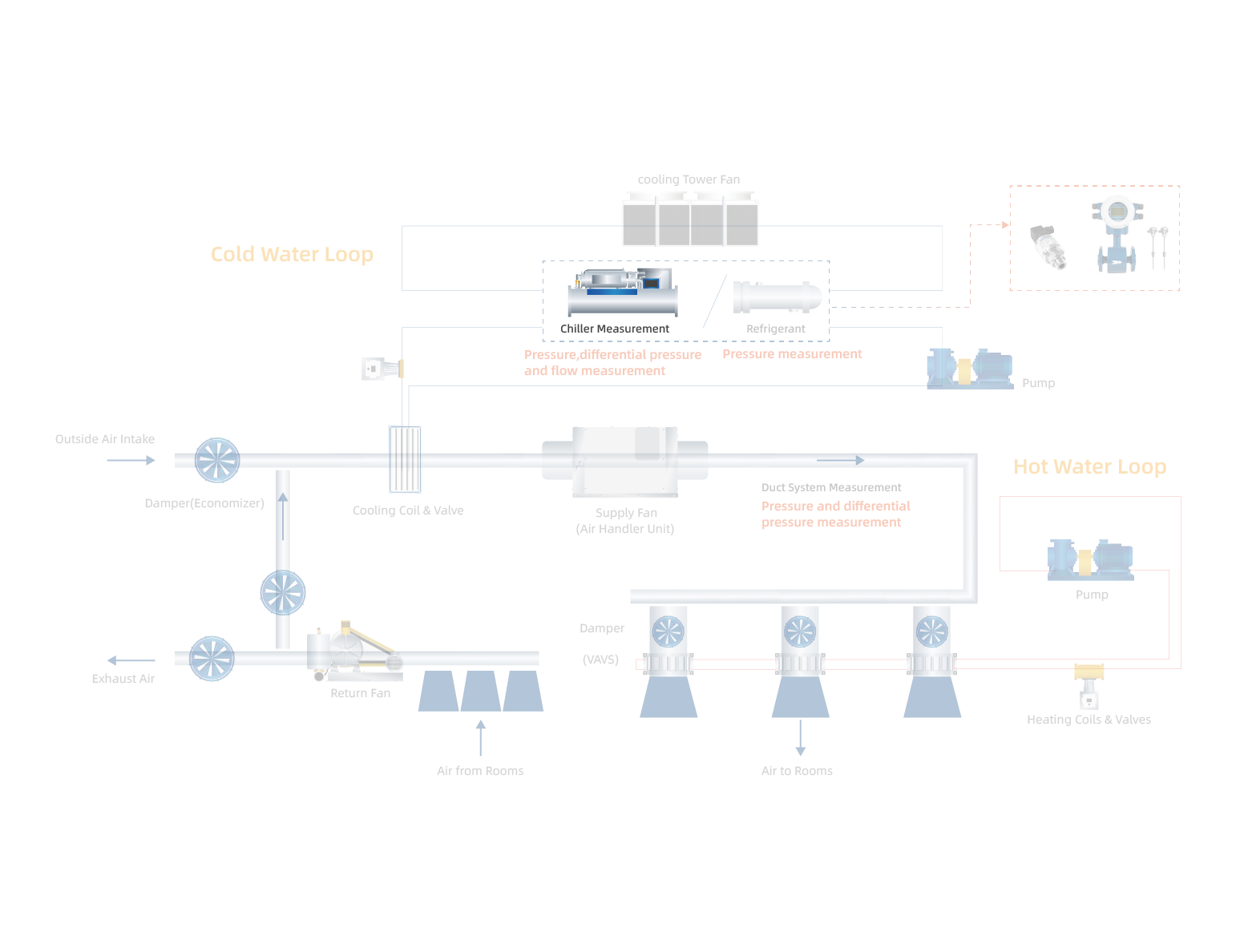

In the HVAC chiller systems, measuring heat and pressure is vital for optimal performance. Pressure transmitters ensure the refrigerant operates within safe limits, while flow meters and temperature sensors calculate heat exchange efficiency. Accurate measurements enhance system reliability, and efficiency, and prevent potential failures.

more info...

The pulp undergoes high-temperature bleaching in a tower using peroxides, ozone, or oxygen to get the right white color. The tower usually stays empty while the large amount of bleached pulp is dumped via a screw conveyor.

more info...