Digital Pressure Transmitter

Range:0.07Bar~1000Bar

Accuracy: ± 0.25%FS

General use structure

MPM4780W

Used For

Tanks Level Measurement, Water Treatment, Oil&Gas Industy

Leave a MessageMPM4780W Intelligent Level Transmitter is a high stability measurement product with integrated design. MPM4780W is a standard digital output, intelligent HART, RS485 and ModBus protocol optional. The product has good output consistency and replaceability. MPM4780W has a permanent waterproof IP68 rating for continuous submersion in a water borehole to measure water depth. It allows easy integration with other devices connected to the same monitoring hardware.

The level Transmitter can be used in fields that require high fluid measurement accuracy. For storage tank liquid level measurement, MPM4780W submersible liquid level gauge will be more convenient and accurate. Custom-design is available.

Feature

• Highly integrated, high stability, high accuracy

• RS485, MODBUS protocol output

• Compact size, small size, light weight

Specification

• Range: 0m~3.5m…200mH2O

• Over pressure: 1.5 times FS / 1100bar (min. value is valid)

• Pressure type: Gauge/ Absolute/ Sealed gauge

• Power Supply: 9V~28V DC

• Output signal: RS485 Interface(MODBUS-RTU protocol)

• Accuracy: ±0.5%FS

• Thermal drift: ±0.04%FS/℃ (≤1bar); ±0.03%FS/℃ (>1bar)

• Measurement Error: ±2℃ (For “temperature & pressure type” only)

• Application Temp.: -10℃ ~70℃

• Insulation: 100V, 100M

• Stability: ±0.3%FS/YEAR

• Shock: 20g, 25Hz~2000Hz

• Impact: 100g, 11ms

• Protection: IP68

Image:

MPM4780W Intelligent Level Transmitter is a high stability measurement product with integrated design. MPM4780W is a standard digital output, intelligent HART, RS485 and ModBus protocol optional. The product has good output consistency and replaceability. MPM4780W has a permanent waterproof IP68 rating for continuous submersion in a water borehole to measure water depth. It allows easy integration with other devices connected to the same monitoring hardware.

The level Transmitter can be used in fields that require high fluid measurement accuracy. For storage tank liquid level measurement, MPM4780W submersible liquid level gauge will be more convenient and accurate. Custom-design is available.

Feature

• Highly integrated, high stability, high accuracy

• RS485, MODBUS protocol output

• Compact size, small size, light weight

Specification

• Range: 0m~3.5m…200mH2O

• Over pressure: 1.5 times FS / 1100bar (min. value is valid)

• Pressure type: Gauge/ Absolute/ Sealed gauge

• Power Supply: 9V~28V DC

• Output signal: RS485 Interface(MODBUS-RTU protocol)

• Accuracy: ±0.5%FS

• Thermal drift: ±0.04%FS/℃ (≤1bar); ±0.03%FS/℃ (>1bar)

• Measurement Error: ±2℃ (For “temperature & pressure type” only)

• Application Temp.: -10℃ ~70℃

• Insulation: 100V, 100M

• Stability: ±0.3%FS/YEAR

• Shock: 20g, 25Hz~2000Hz

• Impact: 100g, 11ms

• Protection: IP68

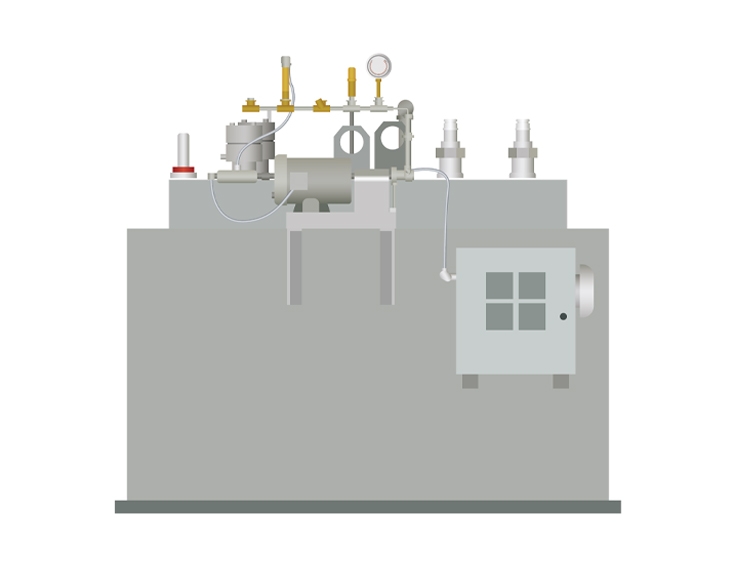

To ensure the fuel supply of the main engine, the separated heavy oil is first pumped to the settling tank, where the oil is heated and separated in the heating coil, and then purified by the oil separator before entering the daily tank through high-level overflow. The daily tank is directly connected to the main engine, boiler or other equipment, and the oil can be heated and used at any time.

more info...

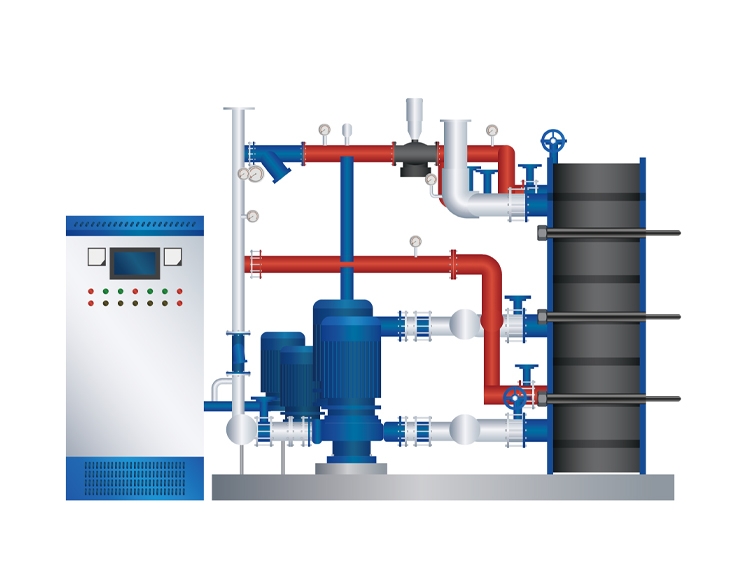

The marine temperature control system uses a refrigerant circulating between the condenser and evaporator to achieve cooling, heating, and dehumidification.

more info...

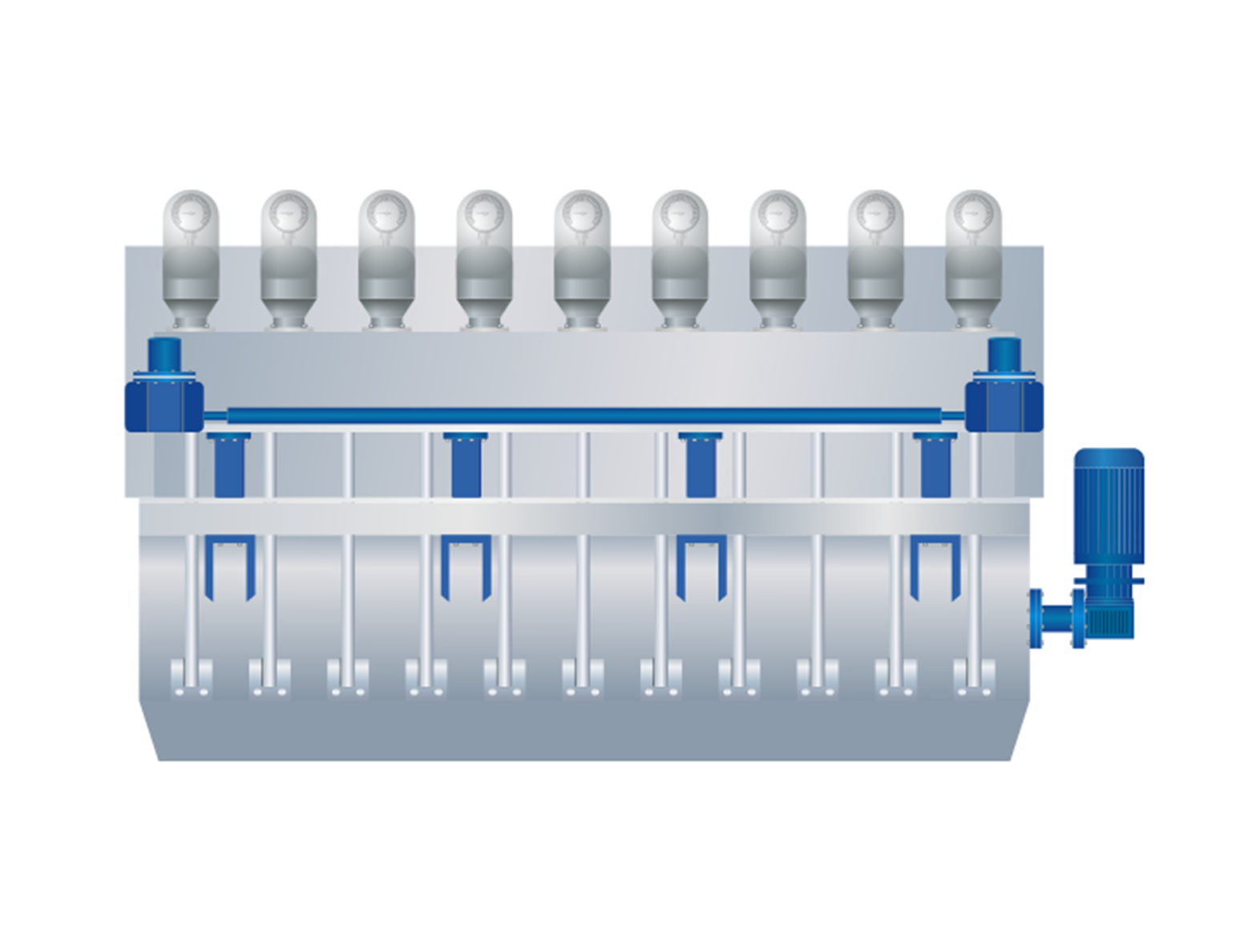

In the papermaking process, pulp is fed into the headbox of the paper machine. In the hydraulic headbox, pulp enters the weir pool via the conical distribution pipe and tube bundles, and is then sprayed onto the forming wire by the weir plate. Since the pulp jet velocity is controlled by adjusting the headbox slice pressure per the wire speed, accurate pressure measurement in the headbox is essential.

more info...

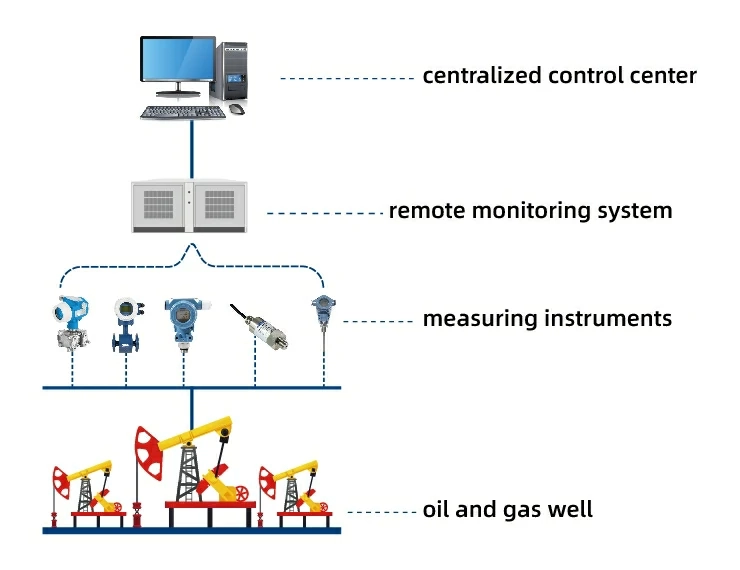

To accurately obtain information about fluid properties, oil layer depth, and other parameters during exploration and extraction, it is necessary to measure formation pressure, fluid density, temperature, and other factors. These data can be remotely transmitted to an online dispatch platform, connected with other oil and gas wells, and integrated into a dedicated IoT network for the oil field. This enables automatic data collection and remote control of oil well production, achieving unified scheduling and intelligent management of oil well production.

more info...