Submersible Level Transmitter

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM426WS

Used For

Metallurgical Industry, Power Plant, Mines, Oil and Gas in Deep Well, Hydrological Exploration

Leave a MessageThe MPM426WS deep water level transmitter is dedicated to measuring oil and gas in deep wells and can be used in harsh environments such as monitoring mine water levels from 350mWC to 2000mWC up to a maximum measurement depth of 2000 metres. In order to improve the sealing performance, the product adopts a special rubber ring bi-directional sealing technology, and the sealing and locking wires are treated separately. For complete sealing and insulation, the cavity is filled with a high vacuum, water and mineral oil resistant sealing silicone material. The product has standard 4~20mA temperature and pressure signal output, and adopts automatic production line to ensure quality, stability and reliability.

Features

• Range: 0mH2O ~ 350mH2O…2000mH2O

• Accuracy: ±0.5%FS (pressure); ±2℃ (temperature)

• Reversed-polarity protection

• Suitable for deepwater level and temperature measurement

Specifications

• Range:

0mH2O ~ 350mH2O…2000mH2O

-20℃ …0℃ ~ 10℃ …80℃;

• Overpressure: ≤2 times FS or 2200mH2O (minimum value is valid)

• Pressure type: sealed gauge, absolute

• Accuracy: ±0.5%FS (pressure); ±2℃ (temperature)

• Zero Thermal Drift: ≤ ±0.02% FS/℃

Image:

The MPM426WS deep water level transmitter is dedicated to measuring oil and gas in deep wells and can be used in harsh environments such as monitoring mine water levels from 350mWC to 2000mWC up to a maximum measurement depth of 2000 metres. In order to improve the sealing performance, the product adopts a special rubber ring bi-directional sealing technology, and the sealing and locking wires are treated separately. For complete sealing and insulation, the cavity is filled with a high vacuum, water and mineral oil resistant sealing silicone material. The product has standard 4~20mA temperature and pressure signal output, and adopts automatic production line to ensure quality, stability and reliability.

Features

• Range: 0mH2O ~ 350mH2O…2000mH2O

• Accuracy: ±0.5%FS (pressure); ±2℃ (temperature)

• Reversed-polarity protection

• Suitable for deepwater level and temperature measurement

Specifications

• Range:

0mH2O ~ 350mH2O…2000mH2O

-20℃ …0℃ ~ 10℃ …80℃;

• Overpressure: ≤2 times FS or 2200mH2O (minimum value is valid)

• Pressure type: sealed gauge, absolute

• Accuracy: ±0.5%FS (pressure); ±2℃ (temperature)

• Zero Thermal Drift: ≤ ±0.02% FS/℃

Φ26mm

0m~1m…200m H2O

Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

DNV approved for installation on all vessels

ATEX Certificated

Contactless Level Measurement

Measuring range: 0m~70m

Measured media: Solid, Liquid

Level / Pressure Measurement: 0mH2O~2mH2O…200mH2O / 0mbar~200mbar...350bar

Output mode: 4mA~20mA, 1V~5V, 0.5V~4.5V...RS485-Modbus, etc.

Low power consumption

ABS, DNV approved for ship use

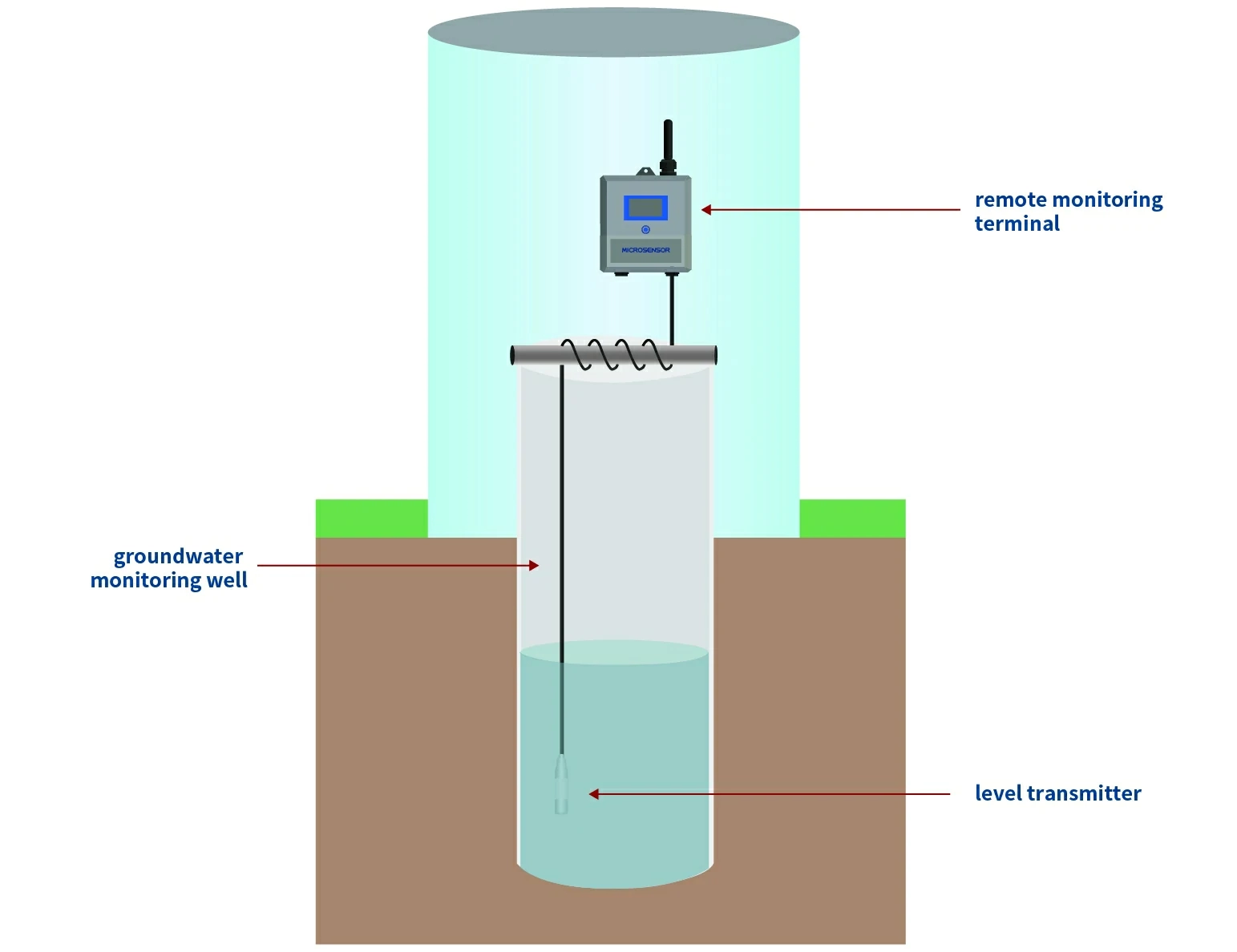

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...

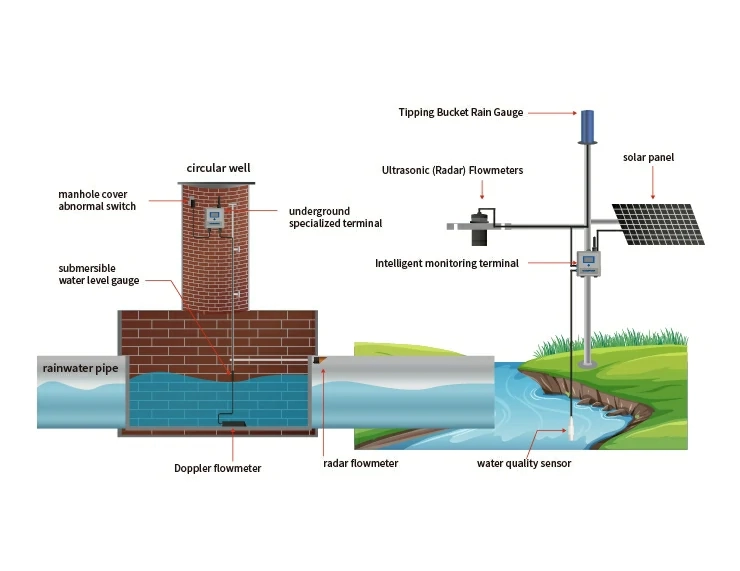

Pressure, level, and flow measurements at the rainwater outlet ensure stable drainage. Monitoring instruments help detection and early warning of pipe burst incidents in time.

more info...

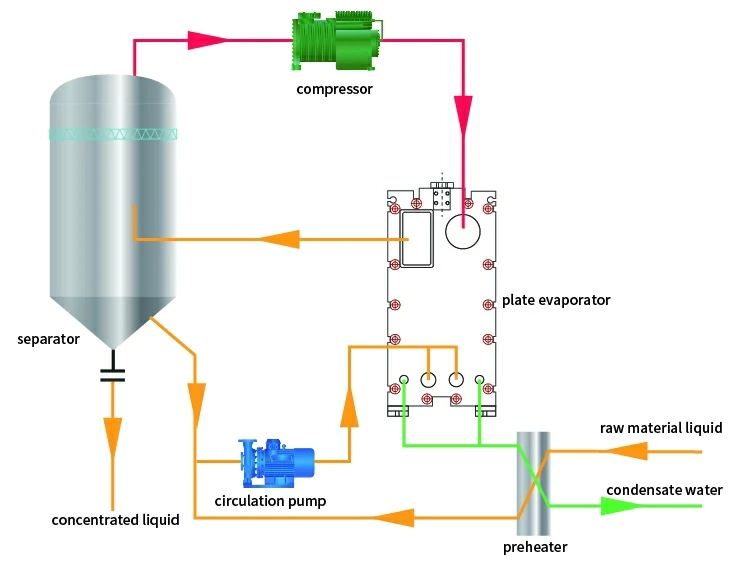

The MVR evaporation equipment requires the use of intelligent pressure transmitters to monitor the liquid level in the separator for feed control. It also monitors the liquid level in the condensate tank, providing timely water replenishment for the condenser, allowing it to condense rapidly. Concurrently, the liquid level height of the raw material tank and the mother liquor tank is monitored. When the liquid level is depleted, raw liquid is added to maintain the normal progress of the process. Intelligent temperature transmitters are used to monitor the steam temperature in the heater, continuously heating the raw liquid for the separation of the solution and the solute. It also monitors the temperature of the separator cavity for efficient separation of the solute and solvent. Flowmeters are used to calculate the volume of the raw material liquid in the feed pump, accumulating the flow.

more info...

During machine downtime or product changes, the press rolls are cleaned and coated with a specialist solution to protect against adhesions and deposits, hence avoiding paper difficulties. The 50°C coating mixture is pushed through the machine. To maintain automated functioning, the tank's level and filter status must be continuously monitored.

more info...