Differential Pressure Transmitter

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

MPM4891

Used For

Mechanical Manufacturing, Petroleum and Petrochemical Industry, Energy and water treatment

Leave a MessageMPM4891 Water Pressure Transmitter is a 2-wire current output pressure transmitter with digital display function. The built-in display screen facilitates on-site viewing of output values. The product can realize manual clearing function in 5 seconds. MPM4891 has stable performance and is widely used for fluid pressure measurement in industrial automation control and other industries.

Micro Senor’s water pressure sensors are cost-effective yet high-accurate and long-term stable. Contact us if you need pressure sensors for water level measurement.

Feature

• For water level measurement

• Digital display function pressure measurement

• Manual clear function

• Meet special customer measurement requirements

Image:

MPM4891 Water Pressure Transmitter is a 2-wire current output pressure transmitter with digital display function. The built-in display screen facilitates on-site viewing of output values. The product can realize manual clearing function in 5 seconds. MPM4891 has stable performance and is widely used for fluid pressure measurement in industrial automation control and other industries.

Micro Senor’s water pressure sensors are cost-effective yet high-accurate and long-term stable. Contact us if you need pressure sensors for water level measurement.

Feature

• For water level measurement

• Digital display function pressure measurement

• Manual clear function

• Meet special customer measurement requirements

0bar~0.35bar...35bar

Accuracy: ±0.5%FS

4~20mA DC 0/1~5V DC 0~10/20mA DC

-1bar...0mbar~100bar…1000bar

General / Flush Diaphragm

CE, RoHS, ATEX approved

DNV and ABS certifications for installation on the ship

Range:-1bar...0~0.1bar…1000bar

Accuracy: ±0.15%FS (Typ.)

RS485/HART Protocol

DNV approved for ship use

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

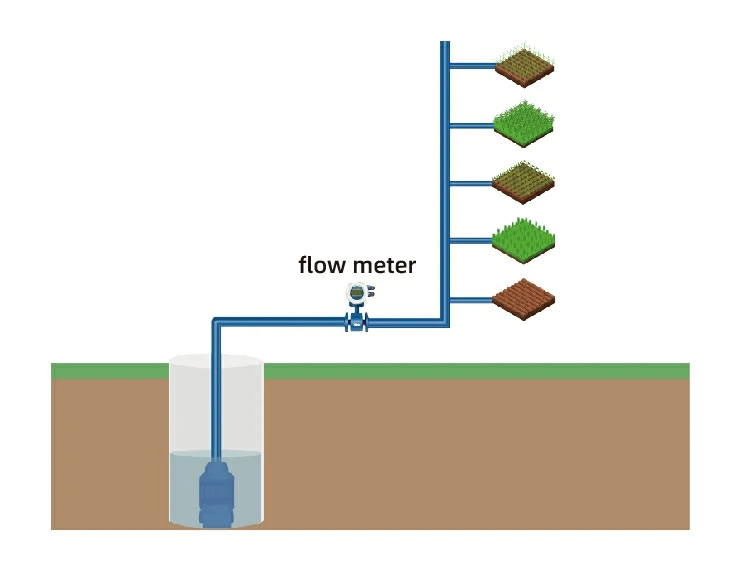

Pipelines are the most common water transportation and irrigation facilities. During transportation, pipelines effectively reduce evaporation and leakage of water resources. Monitoring instruments measure accurately discharge flow. It is a crucial action of rational water resource allocation and reasonable water fee collection.

more info...

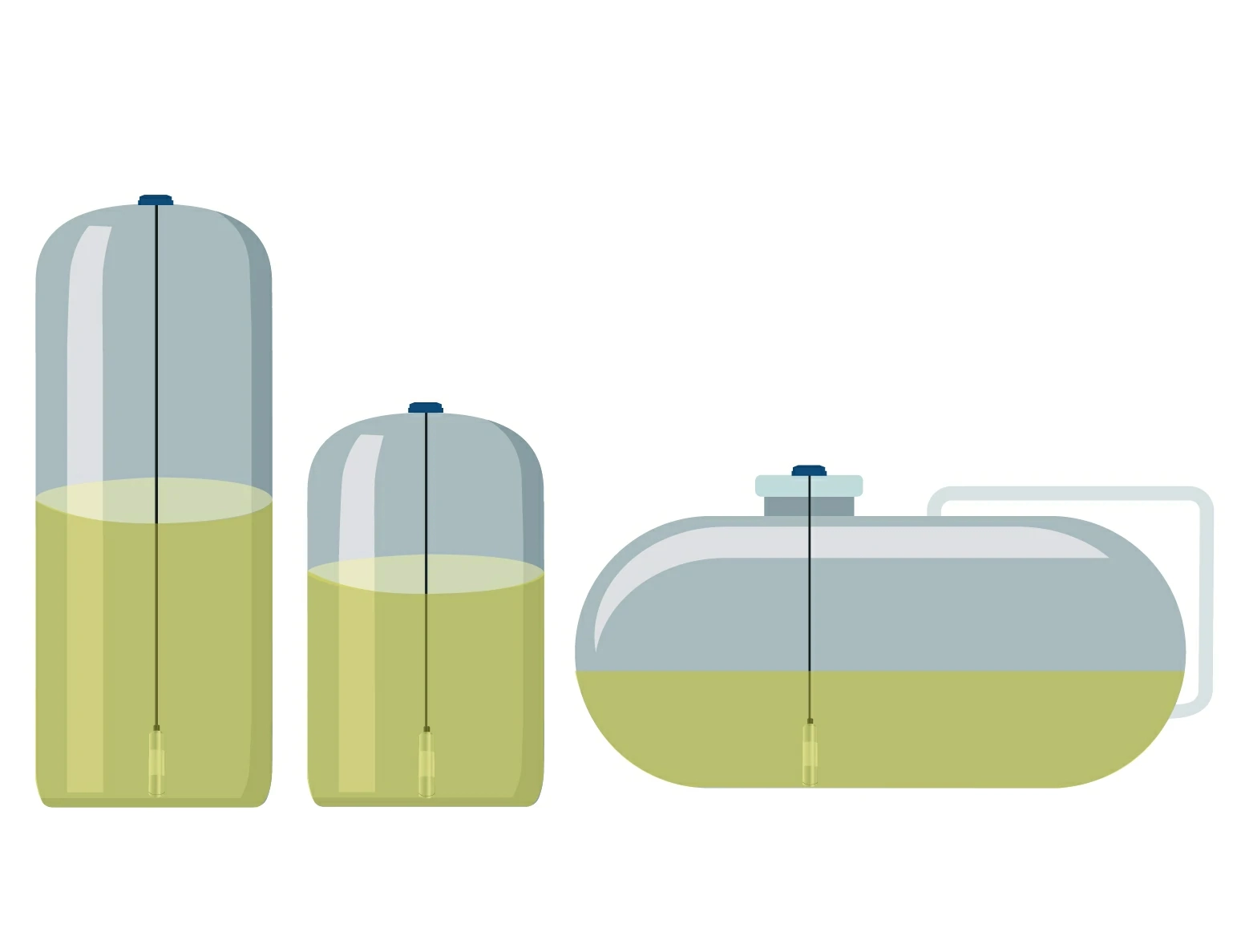

Oil is a high-quality energy and chemical raw material. That is, the "blood of industry". There are various challenges due to different environmental climates and storage conditions all over the world, as well as various unforeseen situations in the process of monitoring of oil tanks.

more info...

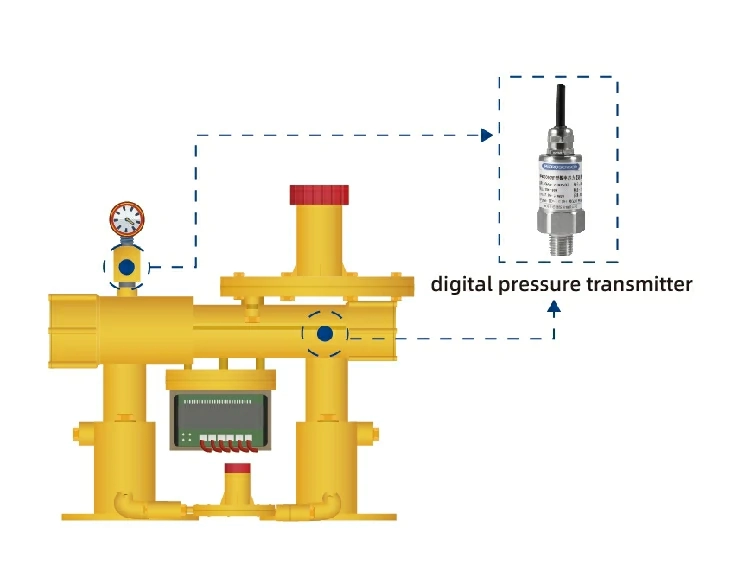

The main function of the gas regulator is to adjust the higher gas inlet pressure to the set lower gas outlet pressure. With a series of changes in gas consumption and inlet pressure, the gas regulator will automatically keep the outlet pressure value within a certain range and play a stabilising role. The pressure transmitter is the core component of the regulator.

more info...

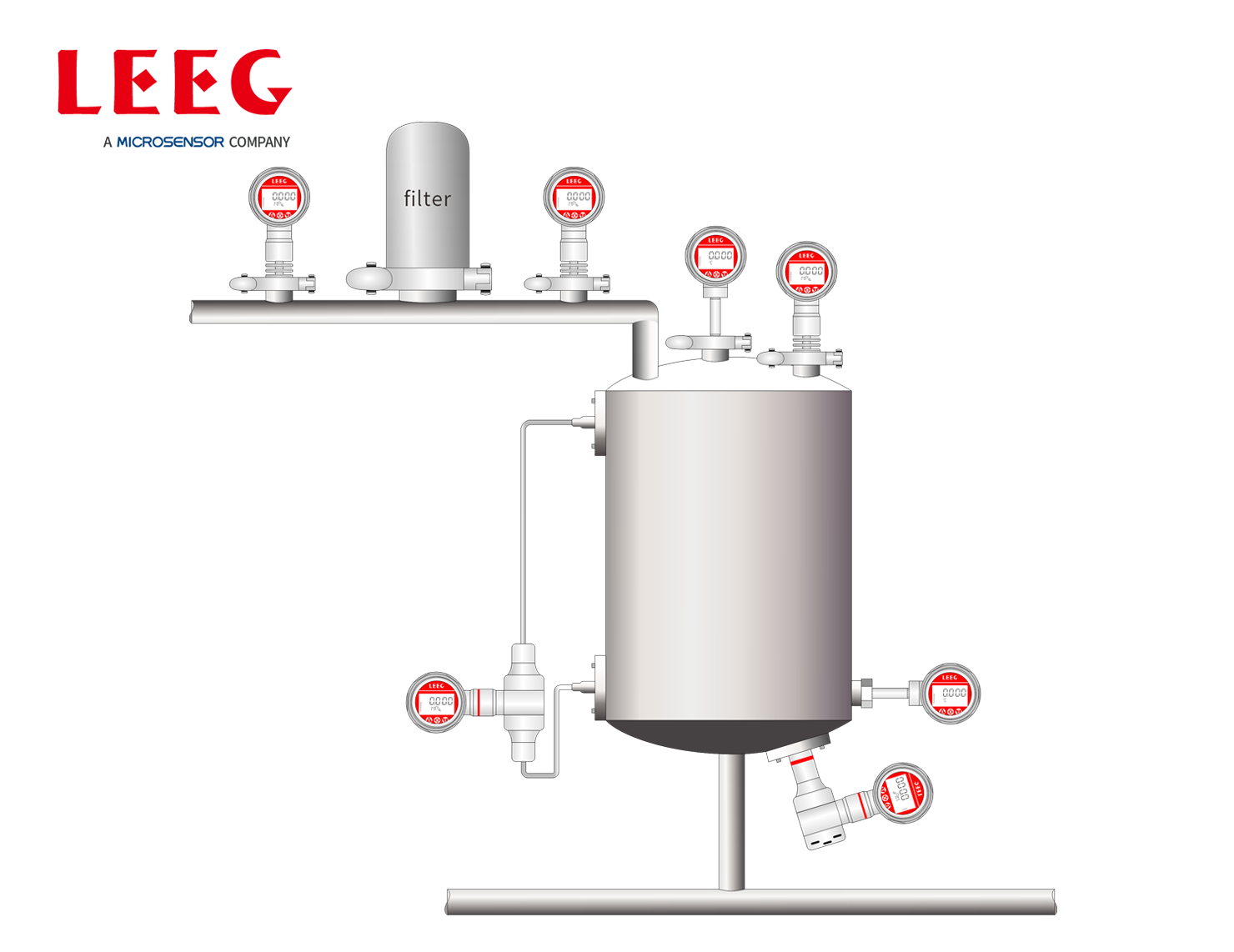

In the pharmaceutical industry, reaction kettles are mainly used to synthesize drugs and their active ingredients, as well as to prepare pharmaceutical intermediates. They are equipped with precise heating and cooling systems that can adjust the reaction temperature as needed to optimize the reaction rate and yield. Besides, the rc can maintain a stable pressure environment.

more info...