Air Sampling Pump

20mL/min~1500mL/min

Accuracy: ±5%FS

IP54, ABS wholly sealed housing

MTMK5883

Used For

Temperature control and detection in heat distribution pipelines, oil storage tanks and industrial automation fields; it can meet the temperature measurement and control requirements of various fields including petroleum, chemical industry, metallurgy, po

Leave a MessageThe MTMK5883 temperature transmitting controller is an intelligent digital temperature measurement and control instrument that integrates temperature measurement, display control, and transmitting output.

The switch can directly measure the surface temperature of various liquids, gaseous media, and solids within the range of -200℃~ 500℃, and output control signals. It employs a temperature sensor known for its exceptional precision and reliability for measurement purposes. The signal is processed by high-precision, low-temperature drift amplification, and converted into a microprocessor digital signal by a high-precision A/D converter. The two-way switch is controlled by the signal after arithmetic processing, then achieves the real-time measurement and control of the on-site temperature system and linear correction. The digital temperature controller is flexible to use, simple to operate, easy to debug, safe and reliable.

Features

• Small meter head, easy to install

• Digital instrument, easy to debug

• Measurement, transmitting, and control in one product

• High precision, high stability, high reliability

• Linear compensation

• Flexible and convenient on-site configuration

It is widely used in thermal pipelines, oil tank inspections, industrial automation control and inspection, etc. It can meet the temperature measurement and control requirements of various fields.

Image:

The MTMK5883 temperature transmitting controller is an intelligent digital temperature measurement and control instrument that integrates temperature measurement, display control, and transmitting output.

The switch can directly measure the surface temperature of various liquids, gaseous media, and solids within the range of -200℃~ 500℃, and output control signals. It employs a temperature sensor known for its exceptional precision and reliability for measurement purposes. The signal is processed by high-precision, low-temperature drift amplification, and converted into a microprocessor digital signal by a high-precision A/D converter. The two-way switch is controlled by the signal after arithmetic processing, then achieves the real-time measurement and control of the on-site temperature system and linear correction. The digital temperature controller is flexible to use, simple to operate, easy to debug, safe and reliable.

Features

• Small meter head, easy to install

• Digital instrument, easy to debug

• Measurement, transmitting, and control in one product

• High precision, high stability, high reliability

• Linear compensation

• Flexible and convenient on-site configuration

It is widely used in thermal pipelines, oil tank inspections, industrial automation control and inspection, etc. It can meet the temperature measurement and control requirements of various fields.

Range: 0~250mbar to 0~250bar

Accuracy:±0.25%FS, ±0.5%FS

Output: 4mA~20mA DC, 0/1V~5/10V DC, 0.5V~4.5V DC

Low Power Consumption

Range: -1bar…0bar ~ 0.1bar…1000bar

Digital temperature compensation and non-linearity modulation

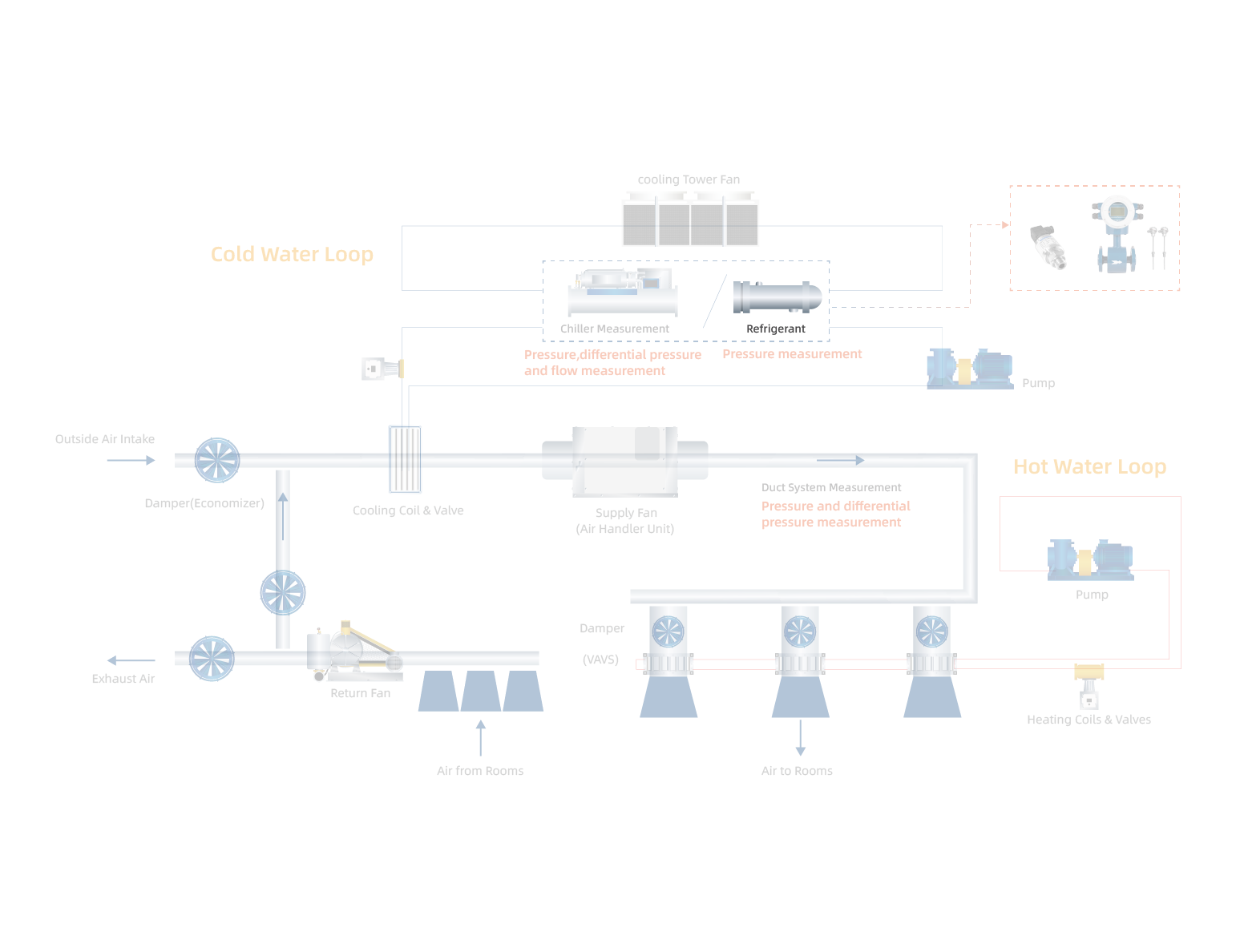

In HVAC systems, measuring the pressure of refrigerants is critical. Pressure transmitters monitor the refrigerant's pressure to ensure it operates within safe limits, preventing leaks and system failures. Accurate pressure measurement enhances system efficiency, ensures optimal cooling performance, and maintains safety by detecting potential issues early

more info...

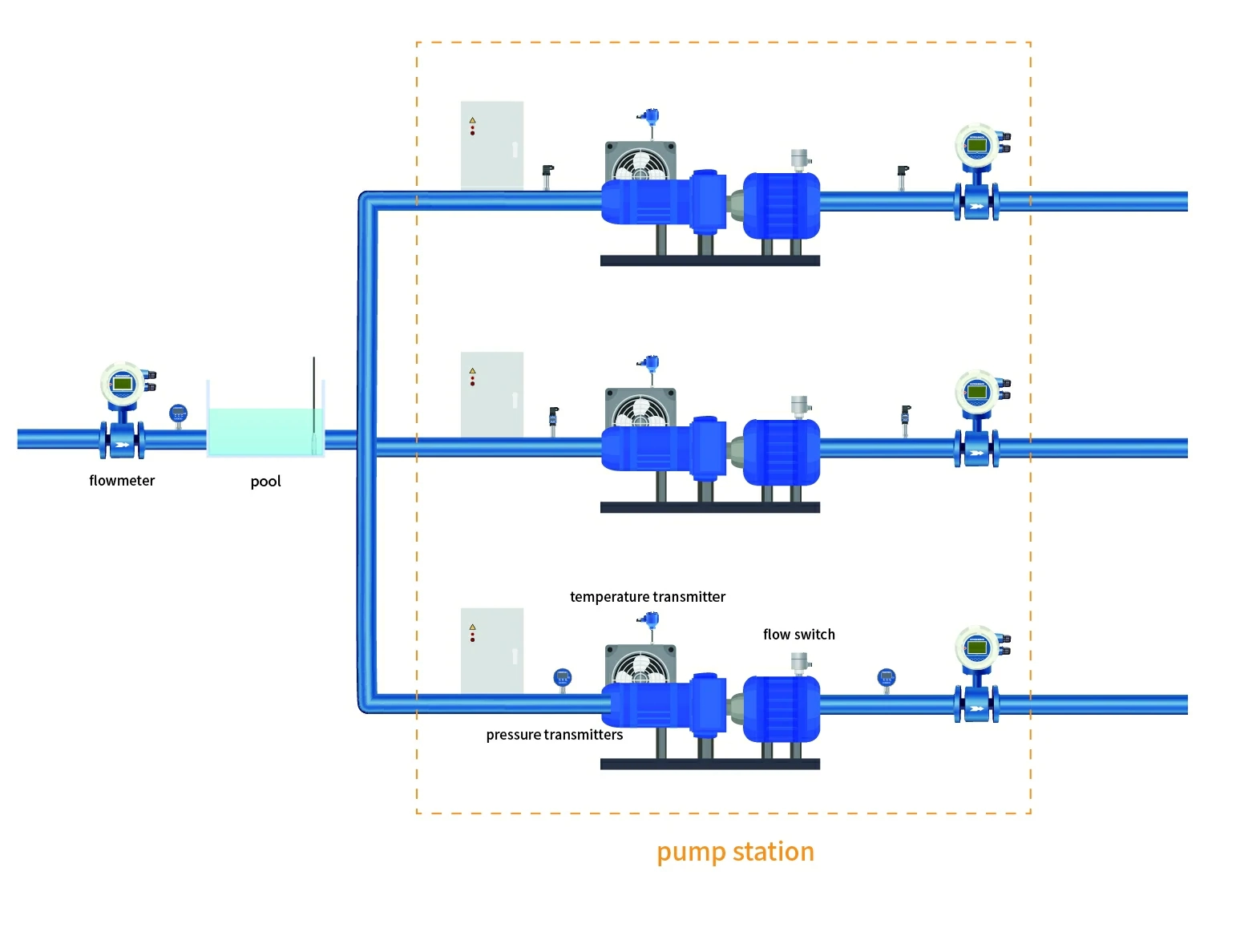

Irrigation and drainage pumping stations solve the problem of gravitational water diversion in irrigation areas, enabling cross-basin water transfer. MicroSensor provides real-time pressure and flow monitoring for inlet and outlet pipelines of these pumping stations, contributing to the accurate measurement of information-based irrigation areas and high-standard farmland construction.

more info...

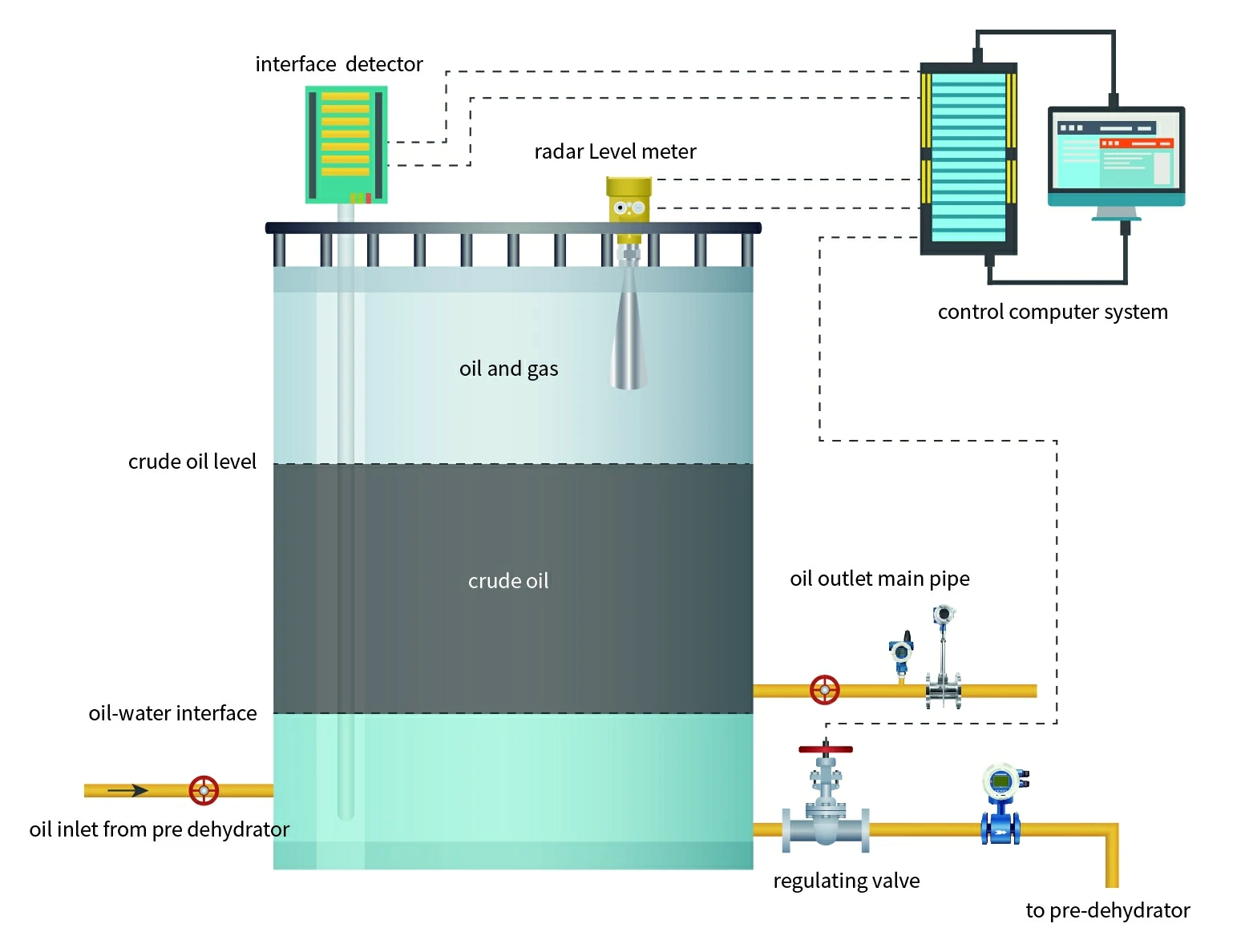

There are a large number of application scenarios of oil, gas, water and other fluid medias in industrial production, which are often stored in tanks of various sizes. Instruments can be installed to monitor the liquid level and pressure changes in the tanks, and automation management can be achieved through platforms and networks.

more info...

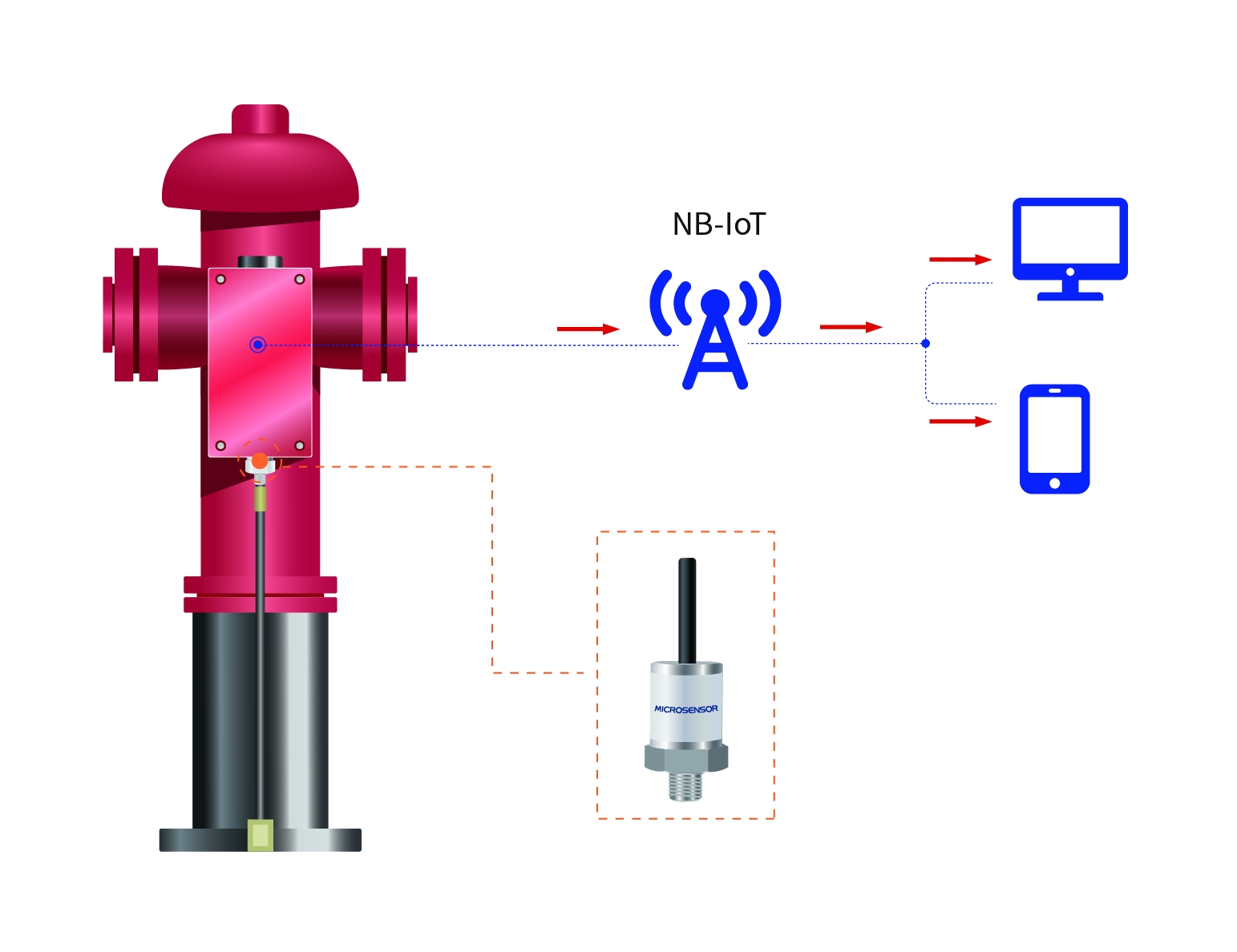

The micro-fused pressure transmitters can be used in hydrants to monitor the internal pressure of hydrants in real time, and send the data to the cloud platform for statistical analysis through wireless monitoring terminals and wireless networks. When an error occurs, it can locate the fault position and sends the alarm in time.

more info...