Differential Pressure Transmitter

Output: mV

Accuracy: 0.25%FS

Max. static pressure 20MPa

MDM492

Used For

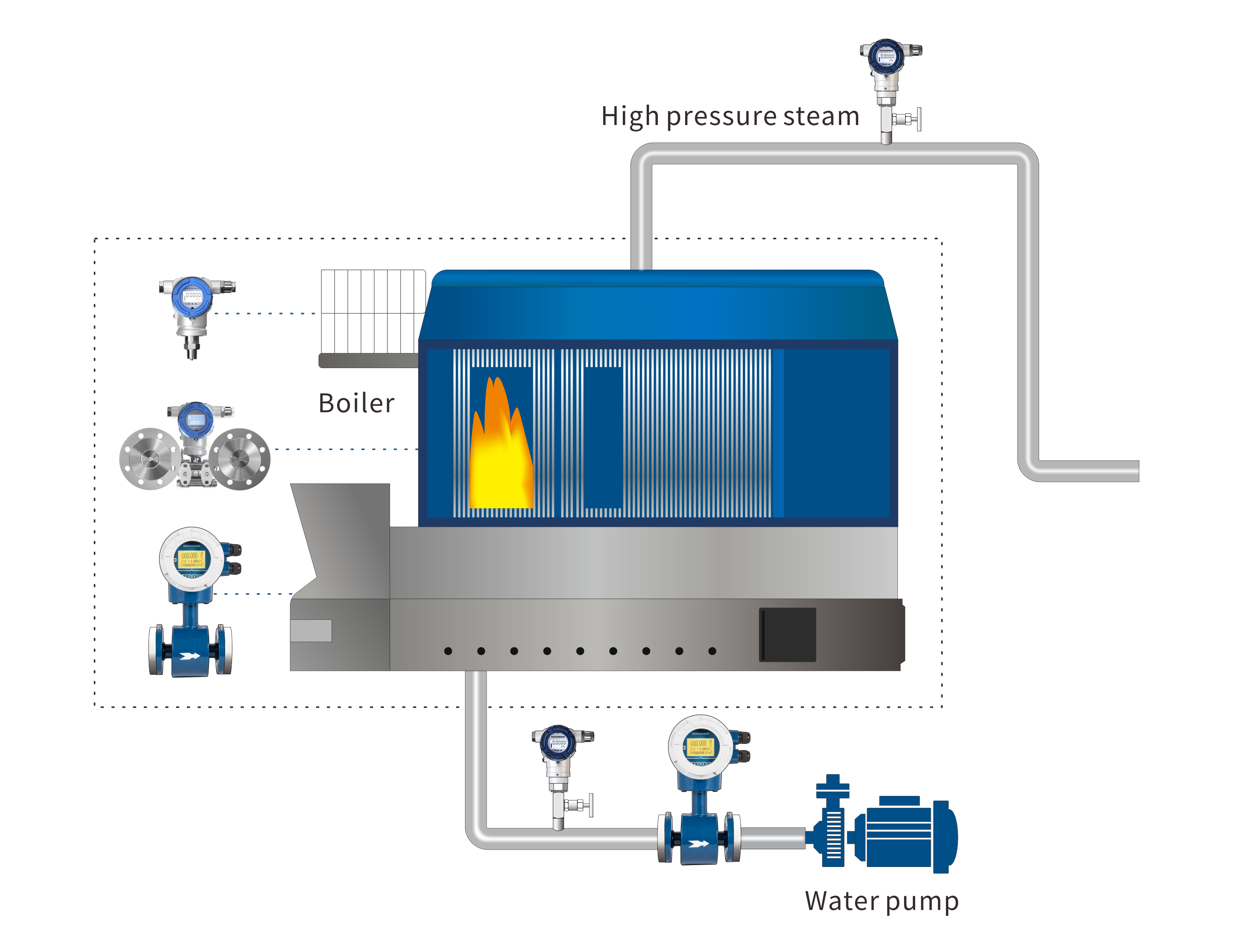

Boiler, Conventional Engine

Leave a MessageMDM492 differential pressure transmitter is specially used for measuring micro differential pressure in boiler, conventional engine applications (gas or non-conductive liquid). It is based on piezoresistive measurement principle and has 3 main pressure ranges, but within these ranges, others could be also achieved by enlarging or shrinking standard pressure range (overpressure unavailable). Combined with a high-performance circuit, this low pressure transmitter outputs a 4-20mA analog signal, which enables a direct connection to the control or monitoring system. The compact design makes it easy for site installation.

Feature

• Differential pressure measurement

• Small size, easy installation

• Suitable for non-conductive, non-corrosive liquid or gas

Specifications

• Pressure range: 0~1kPa 0~2.5kPa 0~7kPa

• Overpressure: 3kPa 7.5kPa 21kPa

• Static pressure: 300kPa 300kPa 300kPa

• Accuracy: ≤1%FS

• Long-term stability: ≤10Pa/year ≤25Pa/year ≤70Pa/year

• Media temp.: -10℃ ~85℃

• Storage temp.: -40℃ ~125℃

• Compensation temp. : 0℃ ~70℃

Image:

MDM492 differential pressure transmitter is specially used for measuring micro differential pressure in boiler, conventional engine applications (gas or non-conductive liquid). It is based on piezoresistive measurement principle and has 3 main pressure ranges, but within these ranges, others could be also achieved by enlarging or shrinking standard pressure range (overpressure unavailable). Combined with a high-performance circuit, this low pressure transmitter outputs a 4-20mA analog signal, which enables a direct connection to the control or monitoring system. The compact design makes it easy for site installation.

Feature

• Differential pressure measurement

• Small size, easy installation

• Suitable for non-conductive, non-corrosive liquid or gas

Specifications

• Pressure range: 0~1kPa 0~2.5kPa 0~7kPa

• Overpressure: 3kPa 7.5kPa 21kPa

• Static pressure: 300kPa 300kPa 300kPa

• Accuracy: ≤1%FS

• Long-term stability: ≤10Pa/year ≤25Pa/year ≤70Pa/year

• Media temp.: -10℃ ~85℃

• Storage temp.: -40℃ ~125℃

• Compensation temp. : 0℃ ~70℃

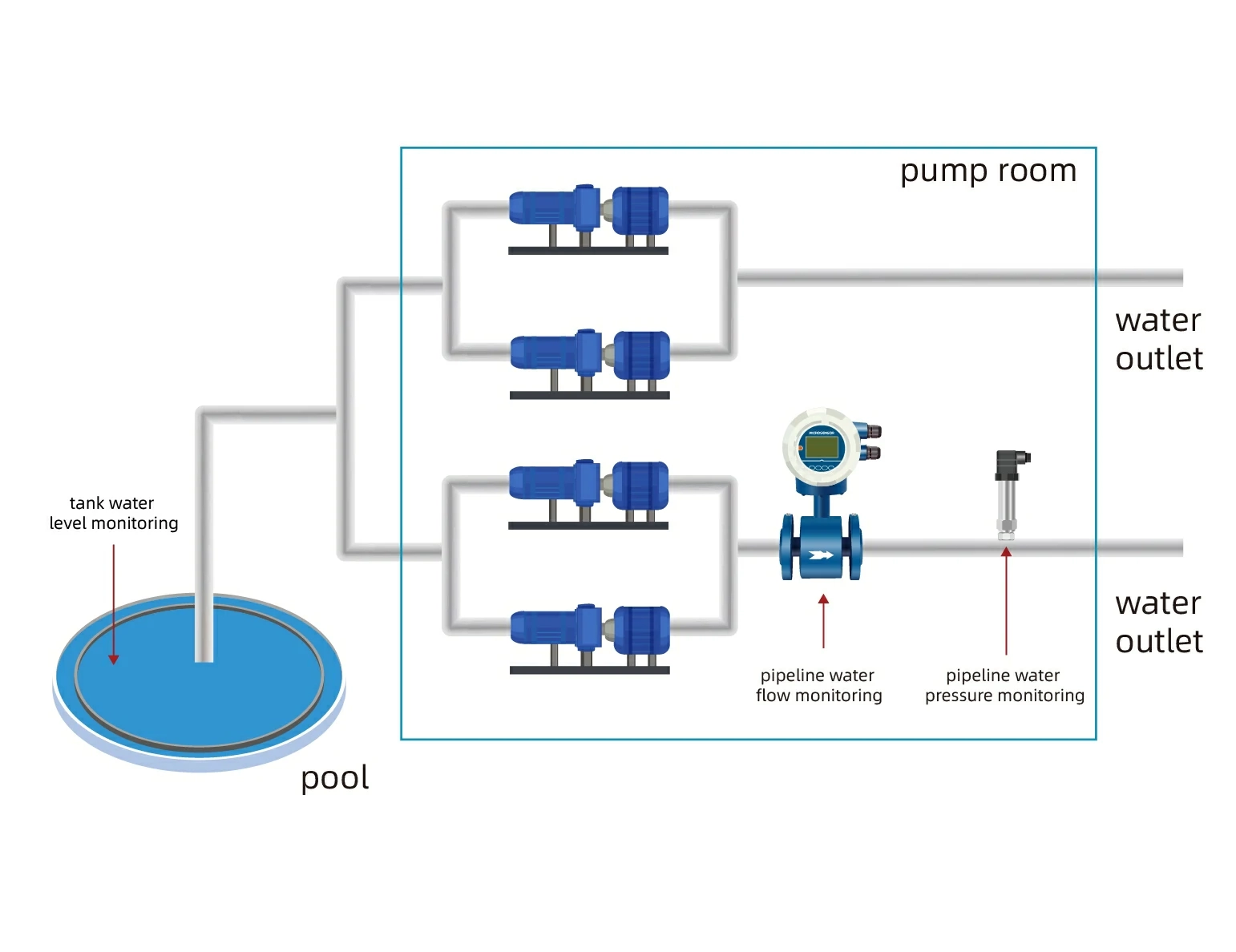

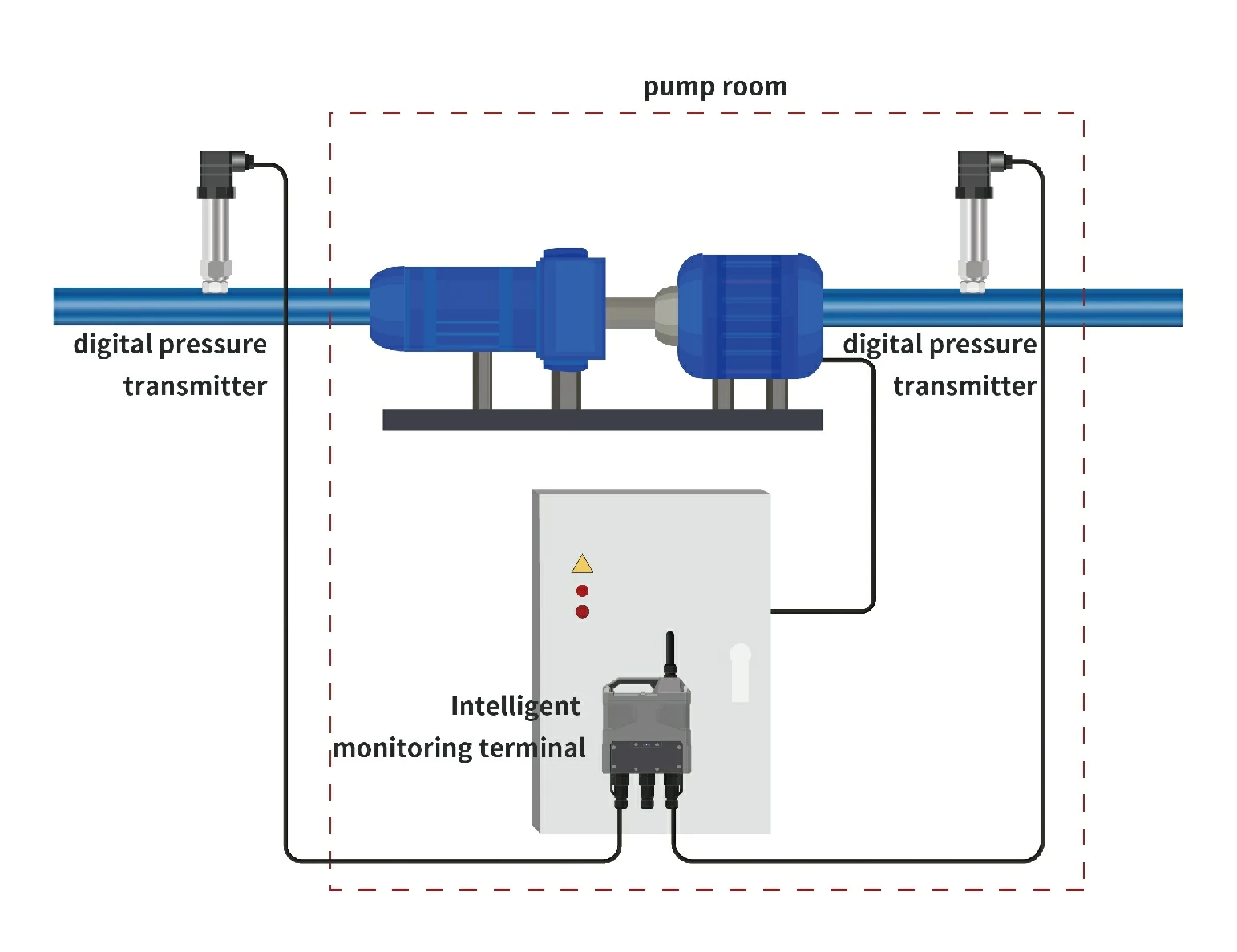

Water storage tank level, pipeline pressure, and flow within the pumping station can transmit status data to the platform via wireless networks. When anomalies are detected, the platform timely alarms. The staff handles fault information immediately. It ensures the normal operation of the water supply system.

more info...

Various monitoring instruments are installed in the water storage tanks, pools, and pipelines of the water supply pump station to monitor the operation of the facilities in real-time. Through advanced cloud computing and big data technology, production data is integrated for timely alarms and early warnings.

more info...

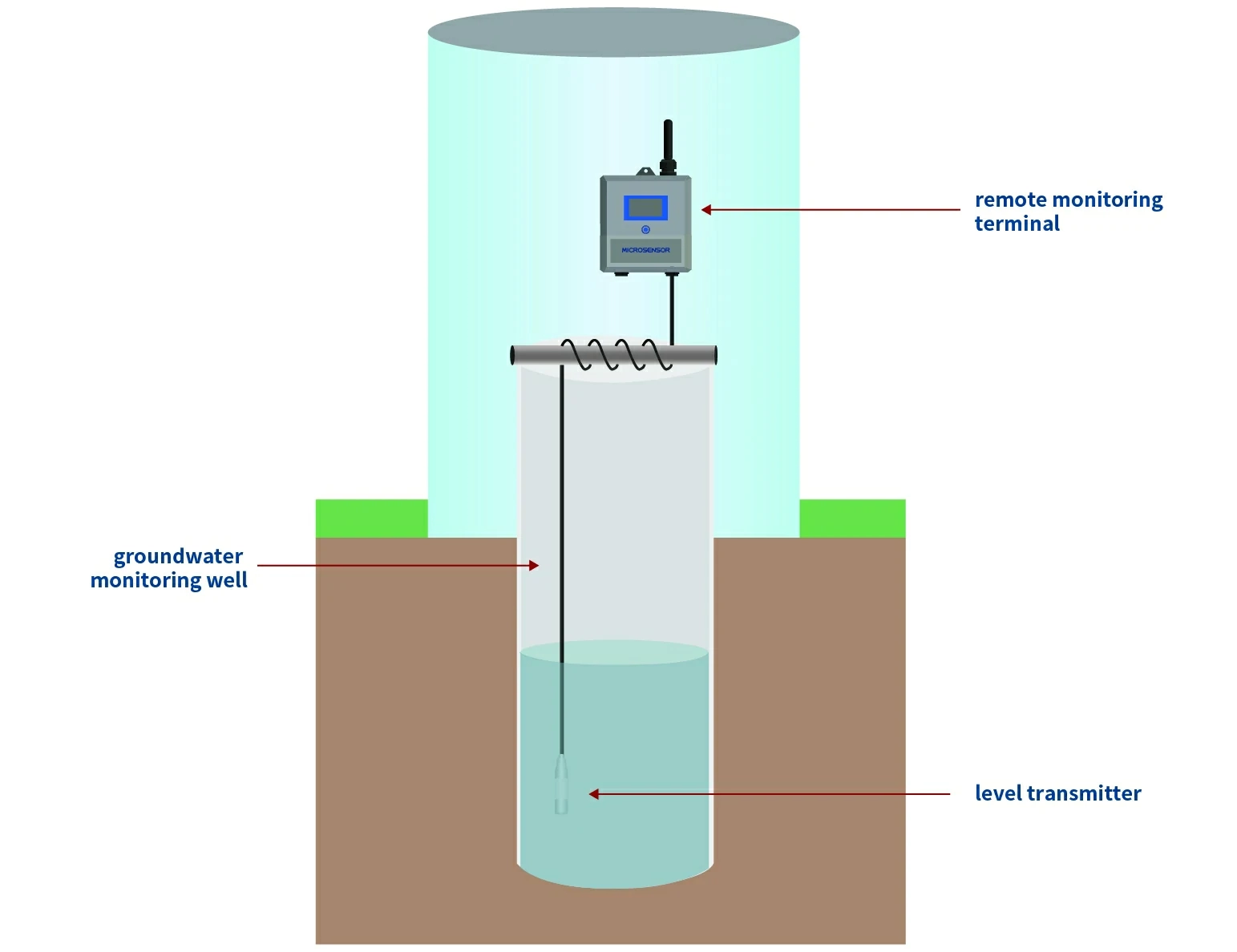

Real-time monitoring of groundwater monitoring wells in the water source area is conducted using monitoring instruments, obtaining data such as water level and flow, thus allowing timely understanding of groundwater resource extraction and usage, providing early warnings, and ensuring the rational use of water resources.

more info...

In the electric power industry, especially in power plants and transmission systems, it is very important to accurately monitor and control pressure, level, temperature and flow, because these specifications will directly affect the operating efficiency and safety of the system. Micro Sensor's monitoring instrumentation solutions integrate advanced sensor technology and intelligent control systems, which can provide accurate data and efficient control even in complex environments, and optimize the power production and transmission process.

more info...