Flushing Ring

Flushing ring: 316 SS

Flange diameter: DN25~DN100, 1-in~4-in

MPM426W

Used For

Petroleum Industry, Chemical Engineering, Power Plant, Urban Water Supply and Drainage, Hydrological Exploration

Leave a MessageMPM426W general submersible level transmitter is widely used in industrial automation and process control. Well-performing pressure components ensure accurate level monitoring. A variety of output signals facilitate integration with various control systems. MPM426W can be used for level measurement of various liquid and solid media, including water, oil, chemical solutions, etc. Ensure production efficiency and safety in chemical industry, food processing, environmental protection and other industries.

Feature

• High precision, small size, easy to use

• Removable design for easy cleaning

• Certificated with CE, RoHS and CCS

Specification

• Measurement Range: 0m~1m...200mH2O

• Overpressure: ≤2 times FS

• Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

• Application Temperature: -20°C ~ 80°C

• Protection Rating: IP68

Image:

MPM426W general submersible level transmitter is widely used in industrial automation and process control. Well-performing pressure components ensure accurate level monitoring. A variety of output signals facilitate integration with various control systems. MPM426W can be used for level measurement of various liquid and solid media, including water, oil, chemical solutions, etc. Ensure production efficiency and safety in chemical industry, food processing, environmental protection and other industries.

Feature

• High precision, small size, easy to use

• Removable design for easy cleaning

• Certificated with CE, RoHS and CCS

Specification

• Measurement Range: 0m~1m...200mH2O

• Overpressure: ≤2 times FS

• Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS

• Application Temperature: -20°C ~ 80°C

• Protection Rating: IP68

Range:-1bar...0~0.2bar…1000bar

Accuracy: 0.5%FS

Output: 4~20mADC, 2-wire

High-level electromagnetic compatibility

Support reverse polarity, transient overcurrent and over-voltage protection

LCD / LED display

CE approved

Measuring range: -50~400℃

Output signal: 4~20mA、Modbus-RTU/RS485 and others

Reference accuracy: ±0.5% upper range limit

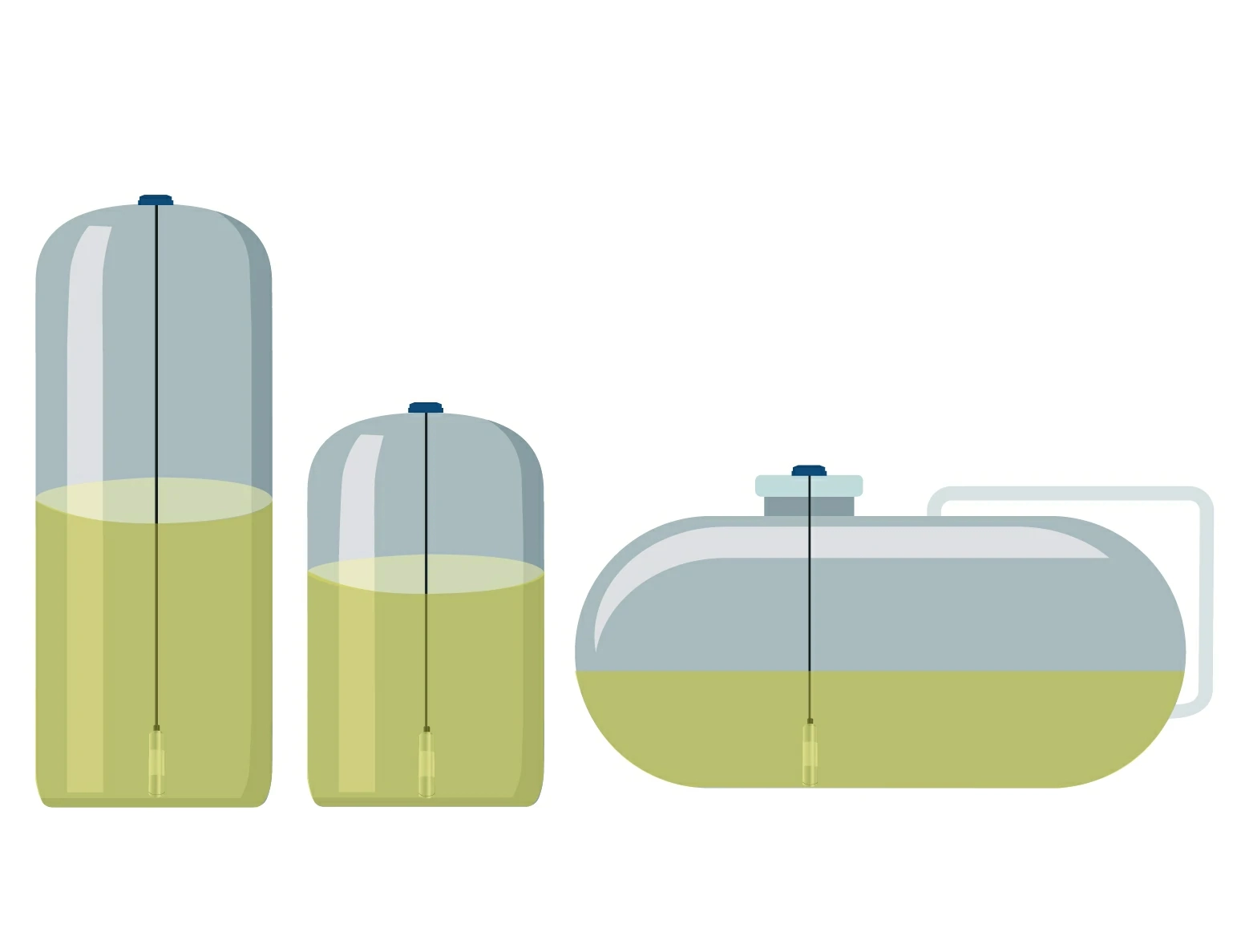

Oil is a high-quality energy and chemical raw material. That is, the "blood of industry". There are various challenges due to different environmental climates and storage conditions all over the world, as well as various unforeseen situations in the process of monitoring of oil tanks.

more info...

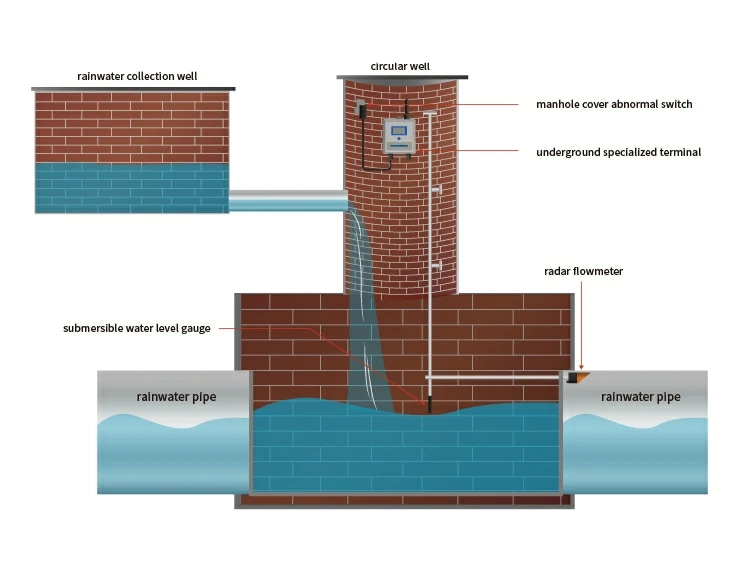

Sump wells are important facilities for convenient daily inspection, prevention, and dredging of drainage pipe blockages. By deploying monitoring instruments at the bottom of the well, a comparison of drainage volume and rainfall is made, allowing for the prediction of flooding points and drainage times under real-time changing drainage conditions. When the water level data exceeds the preset warning value, a timely alarm is given, effectively preventing urban flooding.

more info...

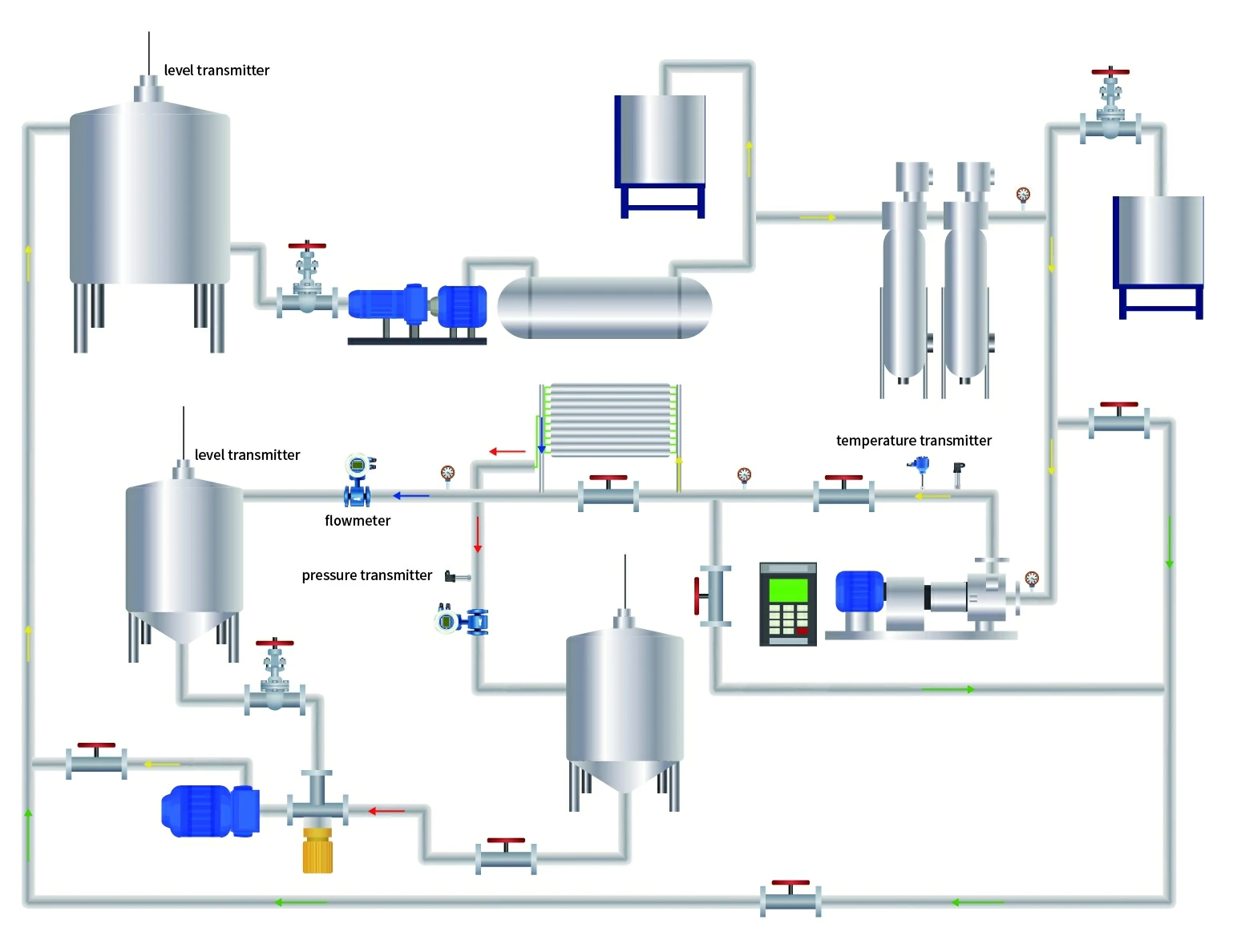

There is a shortage of freshwater resources in coastal or nearshore areas. Desalination is an important solution to water shortages in these areas. During the seawater desalination process, data such as flow rate and liquid level need to be monitored. Monitoring of these data ensures that the system is operating properly.

more info...

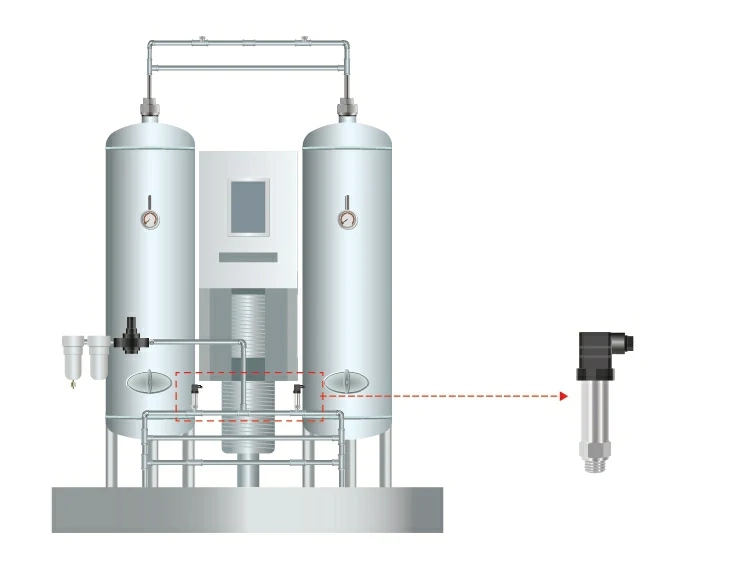

Nitrogen/oxygen generators are widely utilized in electronic equipment, medical devices, air conditioning refrigeration, and food & beverage industries. Pressure transmitters, being vital components of nitrogen/oxygen generators. They monitor the pressure within the container and throughout the variable pressure adsorption process.

more info...