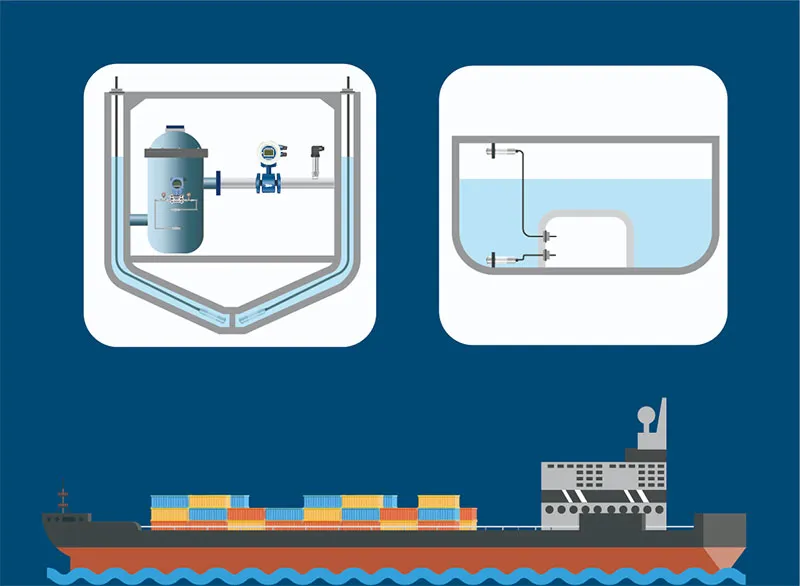

Ballast water is essential to the safe and efficient operation of shipping, the level measurement of ballast water in wing and double bottom tanks are used for the control of ship trim, draught, and list.

Meanwhile, the ballast water poses a serious ecological, economic, and health threat. And the BWMS is designed to solve this problem. There are various types of BWMS, and all of this kind of system requires to measure in-take water flow and system pressure for the controlling. Since these instrumentations are essential, reliability and stability are an absolute must.

Background

While the ship is on the voyage, the fuel, cargo, food, drinking water, etc. on the ship are in customized cabins. Ballast tanks are designed to accommodate ballast water for the purpose of adjusting the ship's trim, heel, draught, center of gravity, and stability. During the operation of the ship, the load and materials for living and fuel on the ship are changing which will change the original draught of the ship. The front and backload capacity changes will affect the navigation performance of the ship.

In order to timely adjust the ship stability caused by the changes in shipborne goods during the operation, the designers design the "ballast water tank", which is distributed in the double bottom tank, the forepeak tank, the tail tip tank, and the side tank or in a deep water tank.

The ship's ballast water system operates by using the pump to inhale or drain off the water in the cabin so that the ship maintains normal ballast and normal trim. For example, due to excessive unloading of cargo on the port side, it will lose ballast and the vessel may be tilted right. At this time, as long as the water is injected into the port side tank, the original ballast will be restored and the vessel is smoothed.

Pressure and Level Measurement

The purpose of the ship's ballast water tank level measurement or pressure measurement for ballast water is to adjust the ballast water timely according to the ship's operating conditions.

Apart from the power system piping necessary for the normal navigation of the main engine, the piping system of the ship power device also consists of the ballast water system, the bilge water system, and the water firefighting system for ensuring the safe operation of the ship.

All three systems use seawater as a medium to share one seawater main pipe. If necessary, the seawater main supply pump, firefighting pump or general service pump can be taken care of or shared with each other.

The ship's ballast water system consists of a ballast water pump, a ballast water pipeline, a ballast water tank, and a valve box. The timely and effective injection, drain off or transfer of ballast water in each ballast tank is to fulfill the purposes below:

(1) Maintain the proper displacement and draft depth of the ship to keep the vertical and horizontal balance of the hull;

(2) maintain a certain stability height of the hull;

(3) reduce the deformation of the hull and protect the hull from excessive bending moments from excessive shearing forces;

(4) reduce the vibration of the hull;

(5) Improve the airworthiness of the ship's empty space.

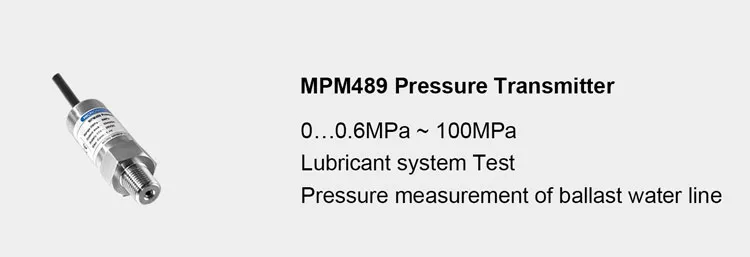

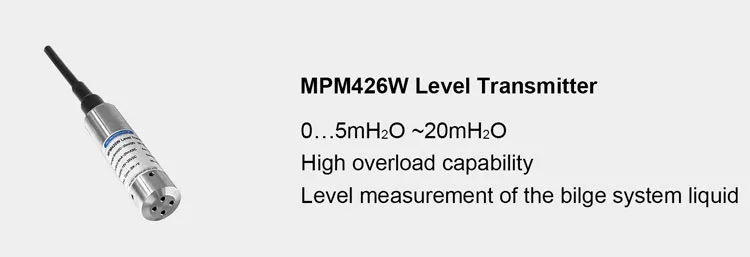

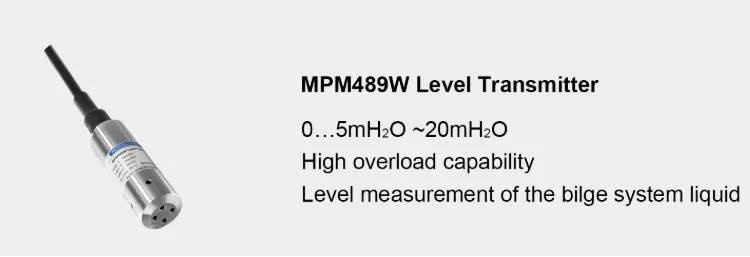

Applicable Products

Certificates

Micro Sensor has a large number of customers application examples in the marine industry. Our ship use pressure and level transmitters are certified by China Classification Society CCS and DNV.GL.

Contact us

The specific application of the transmitter in the marine industry needs to refer to the actual situation, our technical team will provide you with the best product solutions according to the site environment. Feel free to contact sales@microsensor.cn

Previous posts: Level Measurement for Chemical Tank on the Ship

Next chapter: Pressure Sensors Applied in Airborne Engines

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD