Anti-corrosive Pressure Sensor

Φ19mm

-1bar...0bar~1bar…700bar

Tantalum Diaphragm

New Product Change Notice (PCN) effective Jan 1, 2025. MICROSENSOR appreciate your understanding.

MPM280TS

Used For

Chemical Processing, Oil and Gas Production, Water Treatment

Leave a MessageMPM280TS Anti-corrosive Pressure Sensor is made of corrosion-resistant materials to resist the erosion of corrosive media. Tantalum isolated diagram plus SS316L shell housing. Viton O-rings for sealing. Both standard and customized mechanical and electrical configurations are available.

The anti-corrosive property of MPM280TS makes it ideal for use in a wide range of industrial applications, including chemical processing, oil and gas production, and water treatment. By providing accurate and reliable pressure measurements, even in corrosive environments, anti-corrosive pressure sensors help ensure safe and efficient operations, while reducing downtime and maintenance costs.

Specification

• Linearity: Typ. ±0.15 %FS

• Repeatability: Typ. ±0.05 %FS

• Hysteresis: Typ. ±0.05 %FS

• Zero output: Typ. ±1.0 mV DC

• Output/Span**: Min. 70 mV DC

• Zero thermal error: Typ. ±0.75 %FS, @25℃

• FS thermal error: Typ. ±0.75 %FS, @25℃

• Working Temp. Range: -40~125 ℃

• Long-term Stability: Typ. ±0.2% FS/Year

Image:

MPM280TS Anti-corrosive Pressure Sensor is made of corrosion-resistant materials to resist the erosion of corrosive media. Tantalum isolated diagram plus SS316L shell housing. Viton O-rings for sealing. Both standard and customized mechanical and electrical configurations are available.

The anti-corrosive property of MPM280TS makes it ideal for use in a wide range of industrial applications, including chemical processing, oil and gas production, and water treatment. By providing accurate and reliable pressure measurements, even in corrosive environments, anti-corrosive pressure sensors help ensure safe and efficient operations, while reducing downtime and maintenance costs.

Specification

• Linearity: Typ. ±0.15 %FS

• Repeatability: Typ. ±0.05 %FS

• Hysteresis: Typ. ±0.05 %FS

• Zero output: Typ. ±1.0 mV DC

• Output/Span**: Min. 70 mV DC

• Zero thermal error: Typ. ±0.75 %FS, @25℃

• FS thermal error: Typ. ±0.75 %FS, @25℃

• Working Temp. Range: -40~125 ℃

• Long-term Stability: Typ. ±0.2% FS/Year

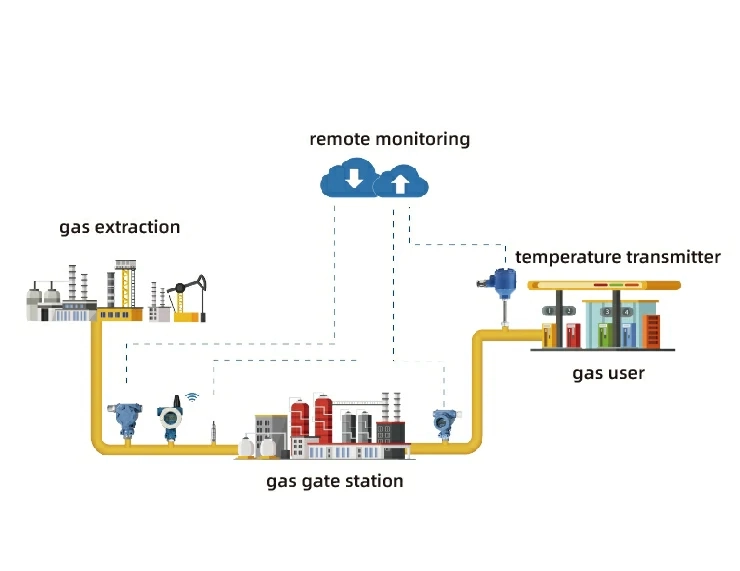

Natural gas undergoes a long process of transportation pipeline transmission, filtration, odorization, and pressure regulation from extraction to end-user consumption. In this process, monitoring the pressure and temperature within the pipeline is critical to ensuring the proper operation of the system.

more info...

Rotary gas meter is the critical equipment in the system of urban gas gate station. As the basis of gas billing, rotary gas meter can accurately calculate the flow of natural gas. It is equipped with pressure transmitter with high accuracy, so as to guarantee the flow accuracy.

more info...

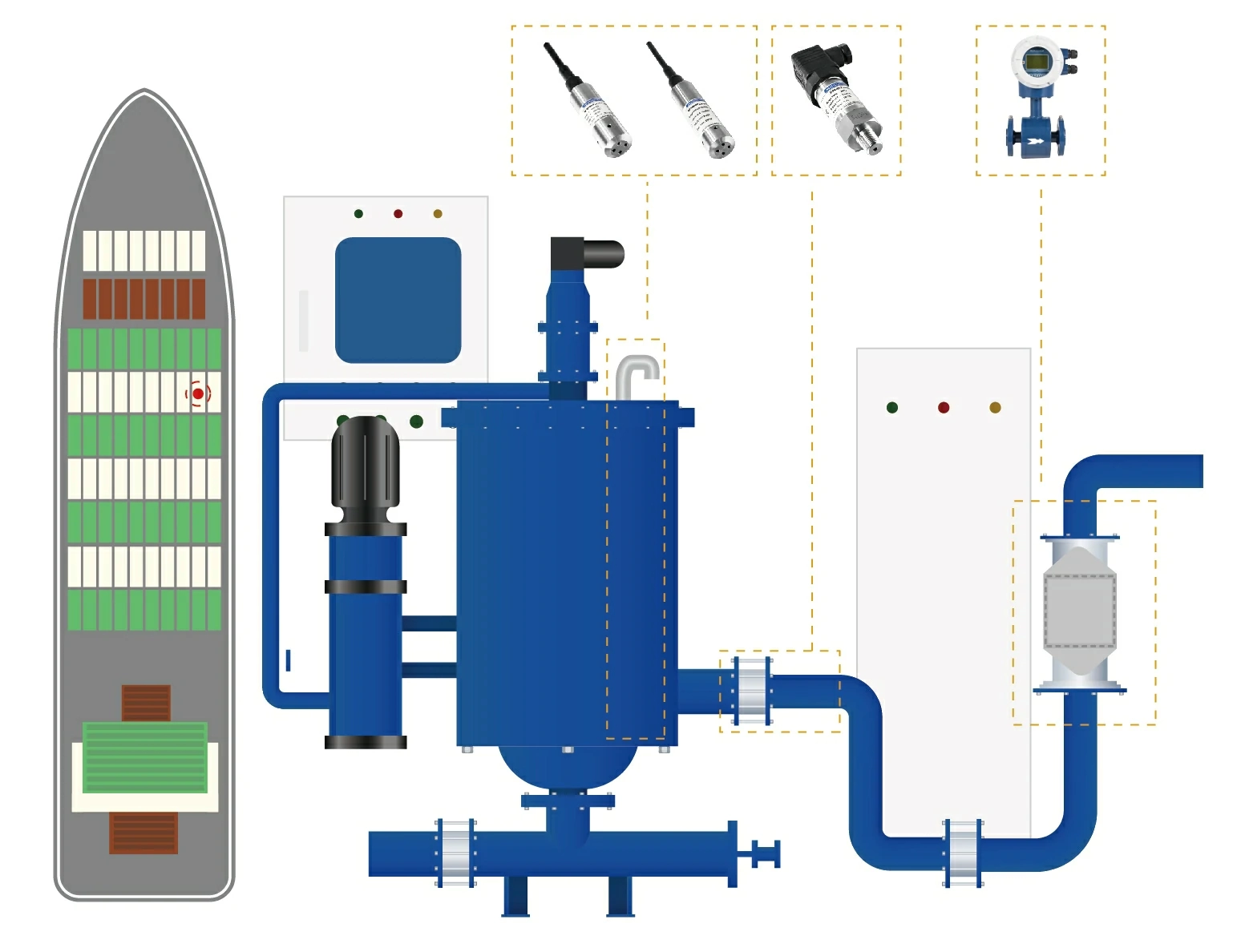

Pressure transmitters, level transmitters, and mass flow meters are installed in fuel tanks to provide real-time monitoring of fuel levels and pressure. Users can track current location and fuel consumption, access historical vessel data, calculate voyage distance and total fuel usage, and analyze operational efficiency.

more info...

Ballast tank level monitoring achieves precise control of the ballast water system by using equipment such as electromagnetic flowmeters, level transmitters, and pressure transmitters to monitor data on inflow, tank liquid level, and pressure.

more info...