Application Introduction

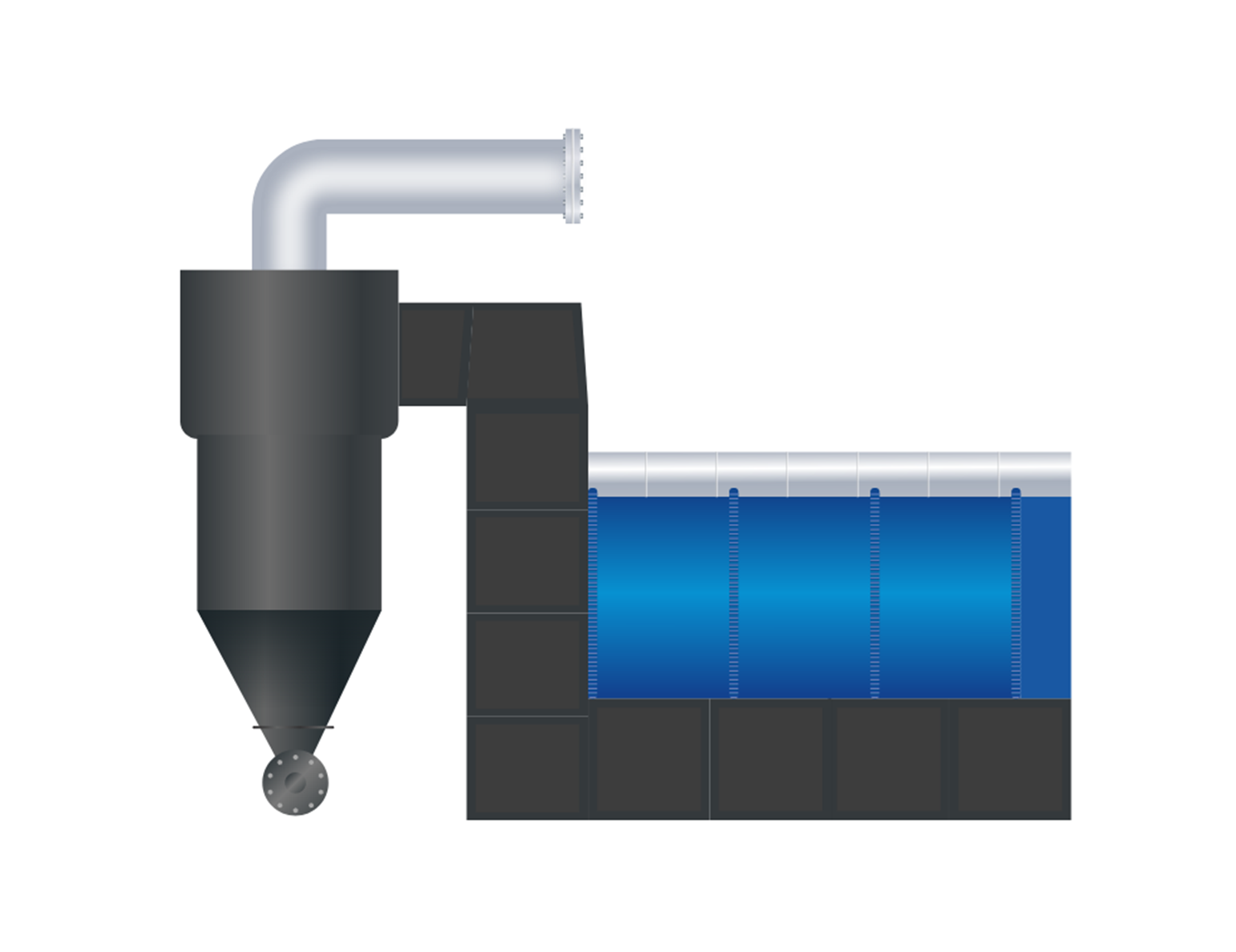

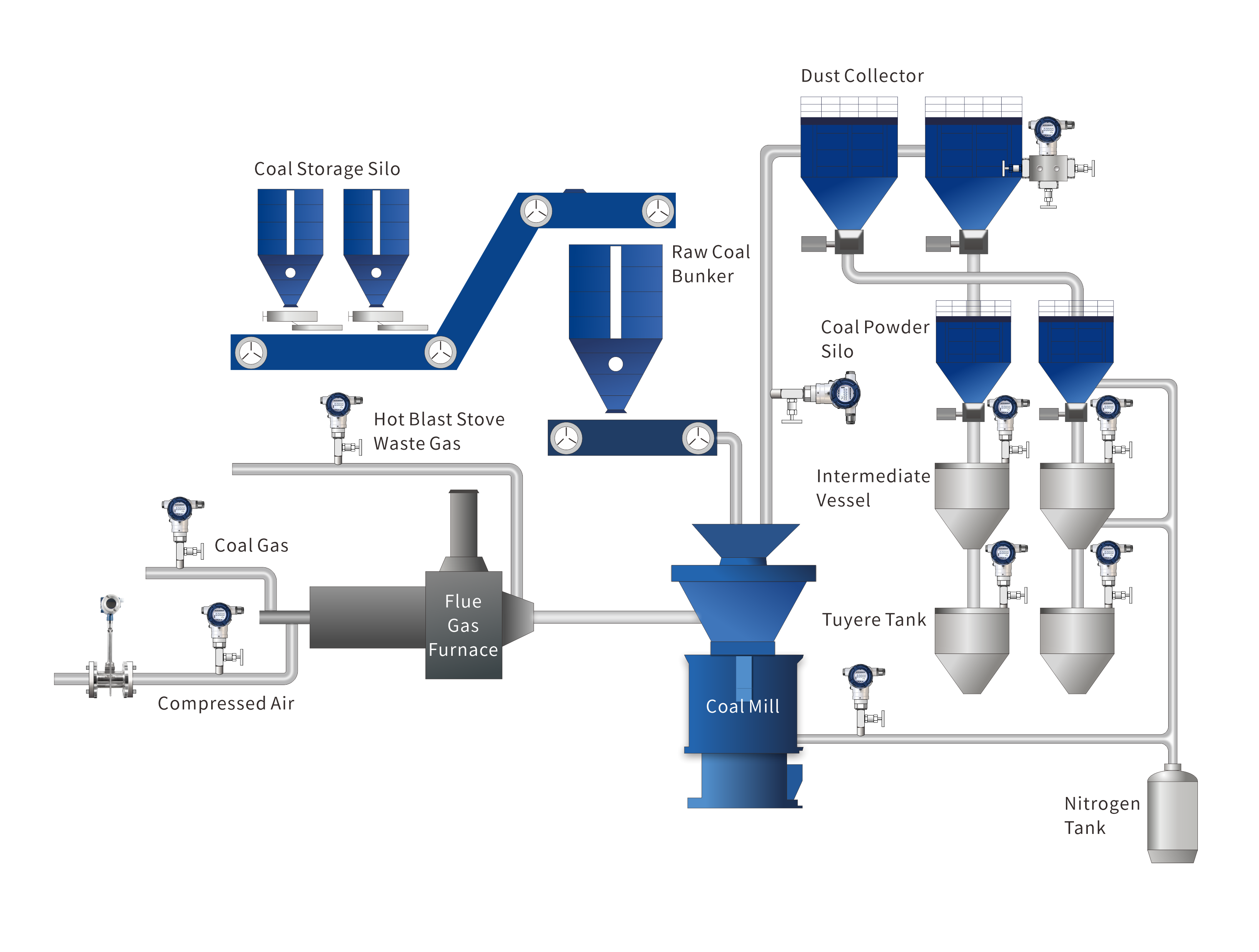

In the paper industry, the alkali recovery system is an essential part that operates under harsh conditions. The system needs strong pressure, temperature, and flow instrumentation to handle high temperatures, high pressures, and corrosive media.

Contact Engineer

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD