Application challenges

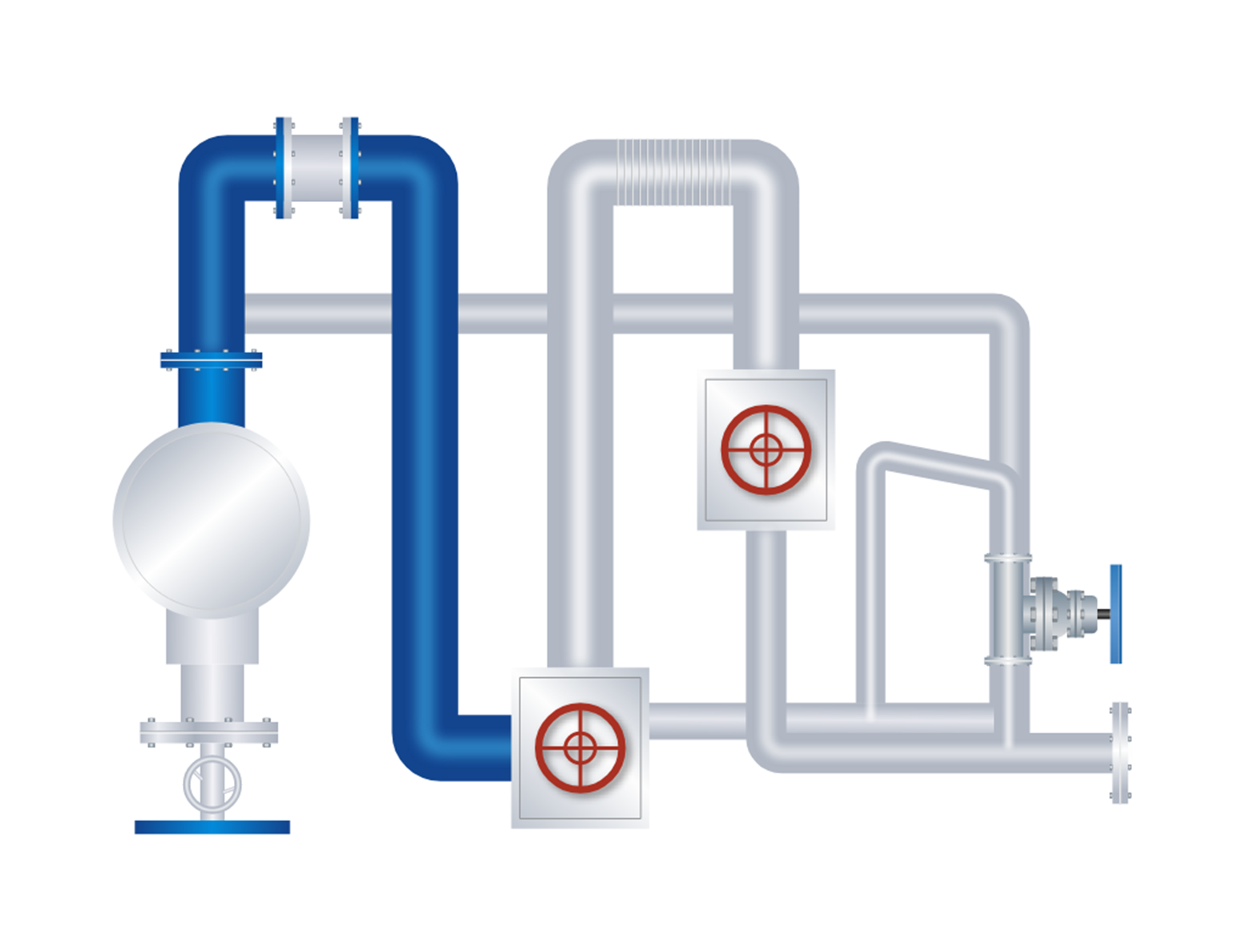

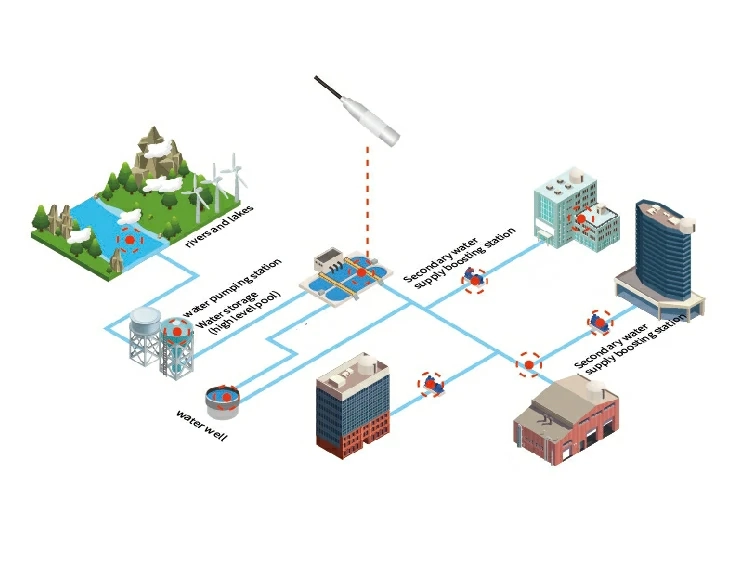

1. Due to the high temperature and pressure of steam pipelines, instruments that can survive harsh circumstances are required.

2. Thermal shocks in steam systems necessitate long-lasting, fast-responding instruments.

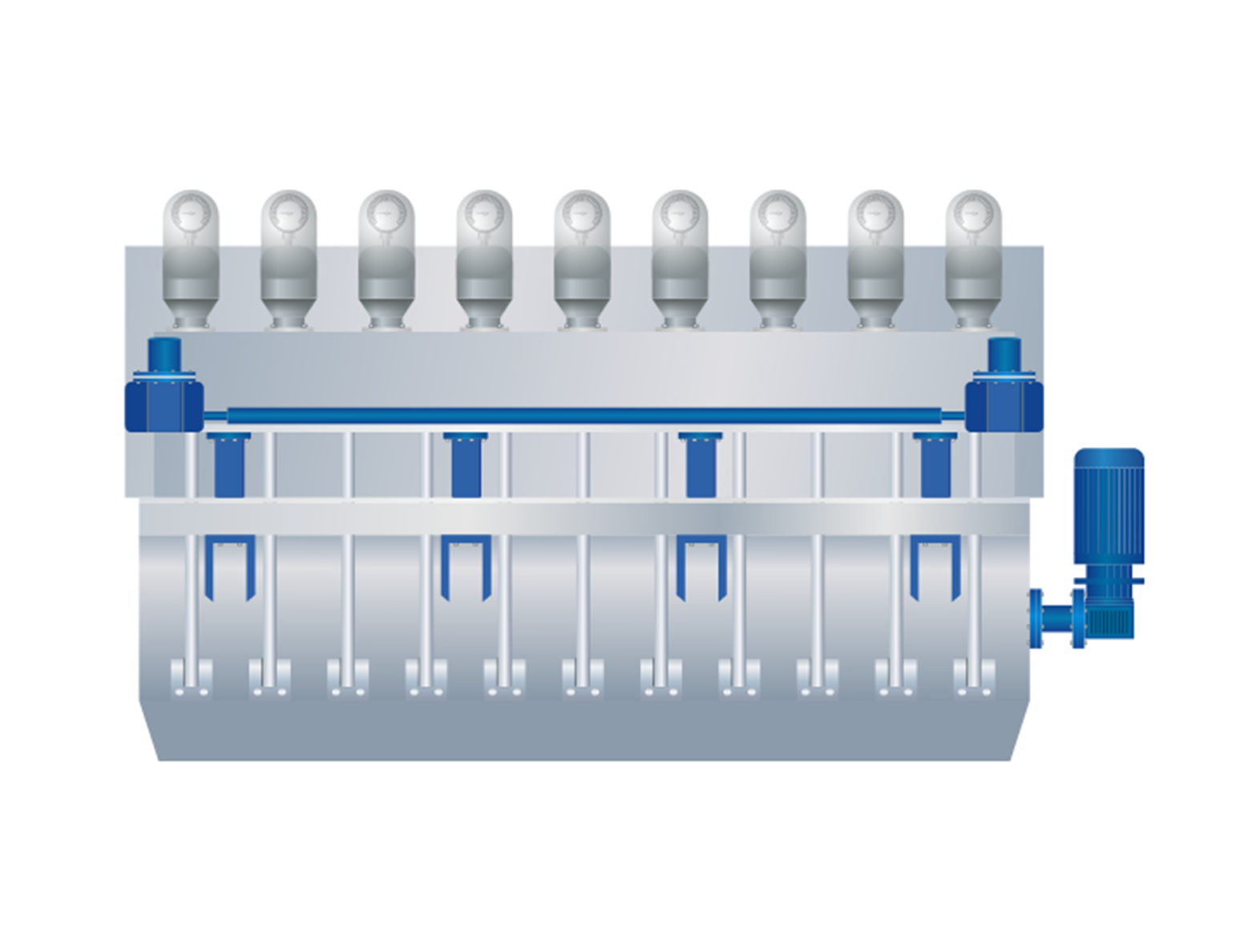

3. Steam's high temperature, pressure, and fluctuating flow necessitate extremely accurate, dependable flowmeters.

4. Steam impurities can cause corrosion and scaling, compromising long-term instrumentation stability.

Solution advantages

1. High-temperature and high-pressure resistant materials and designs ensure operation in high-temperature and high-pressure environments.

2. High response speed and heat shock-resistant design enable accurate measurement even when the temperature changes rapidly.

3. Advanced measurement technologies such as vortex flowmeter and differential pressure flowmeter are used, which have high precision and high stability and are suitable for various steam flow measurements.

4. Corrosion-resistant materials and special coating design are used to effectively prevent corrosion and scaling, and extend the service life of the equipment.

5. Multiple communication protocols and data transmission methods are available, making it easy to integrate with existing control systems, provide real-time data and alarm functions, and improve system efficiency.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD