Application Challenges:

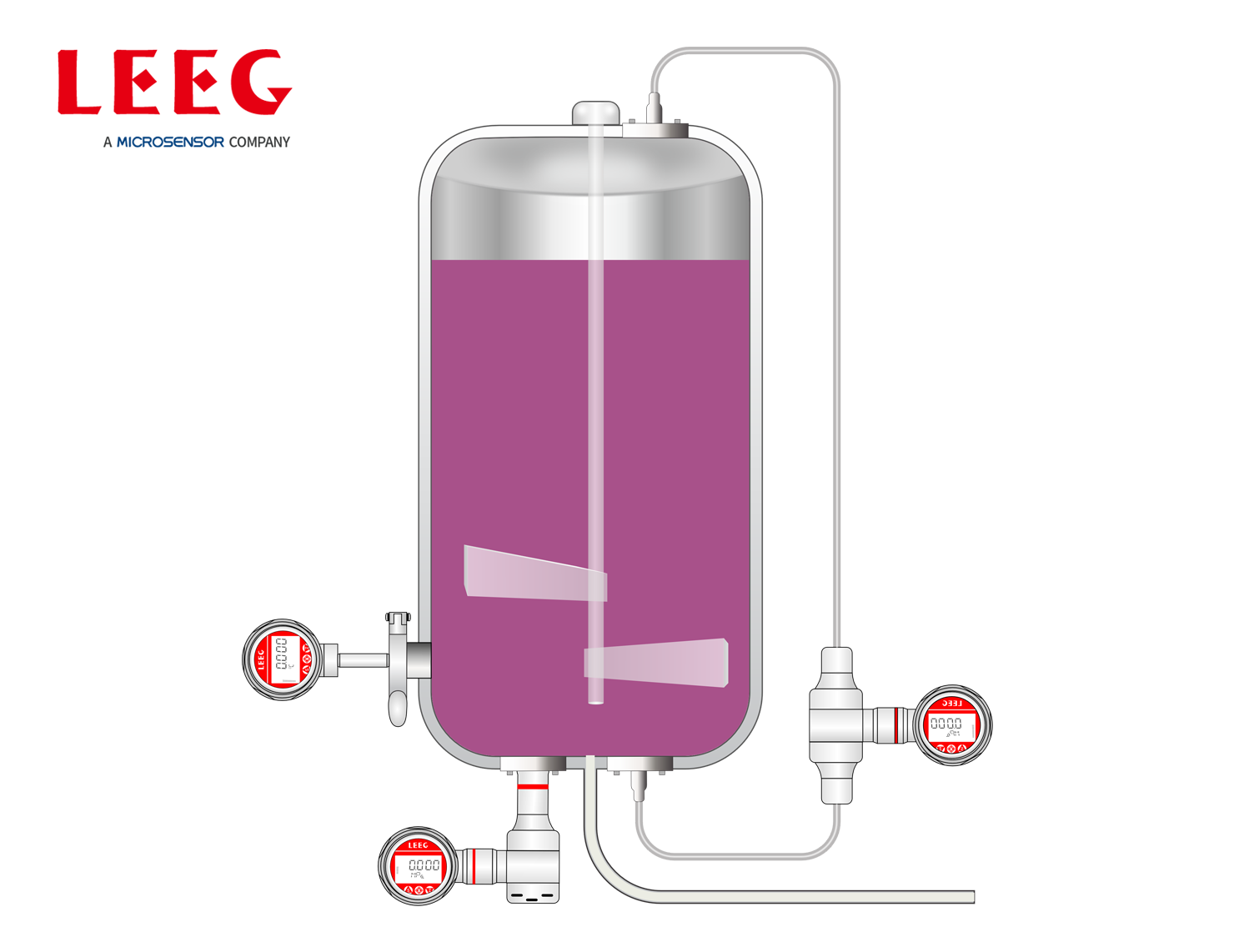

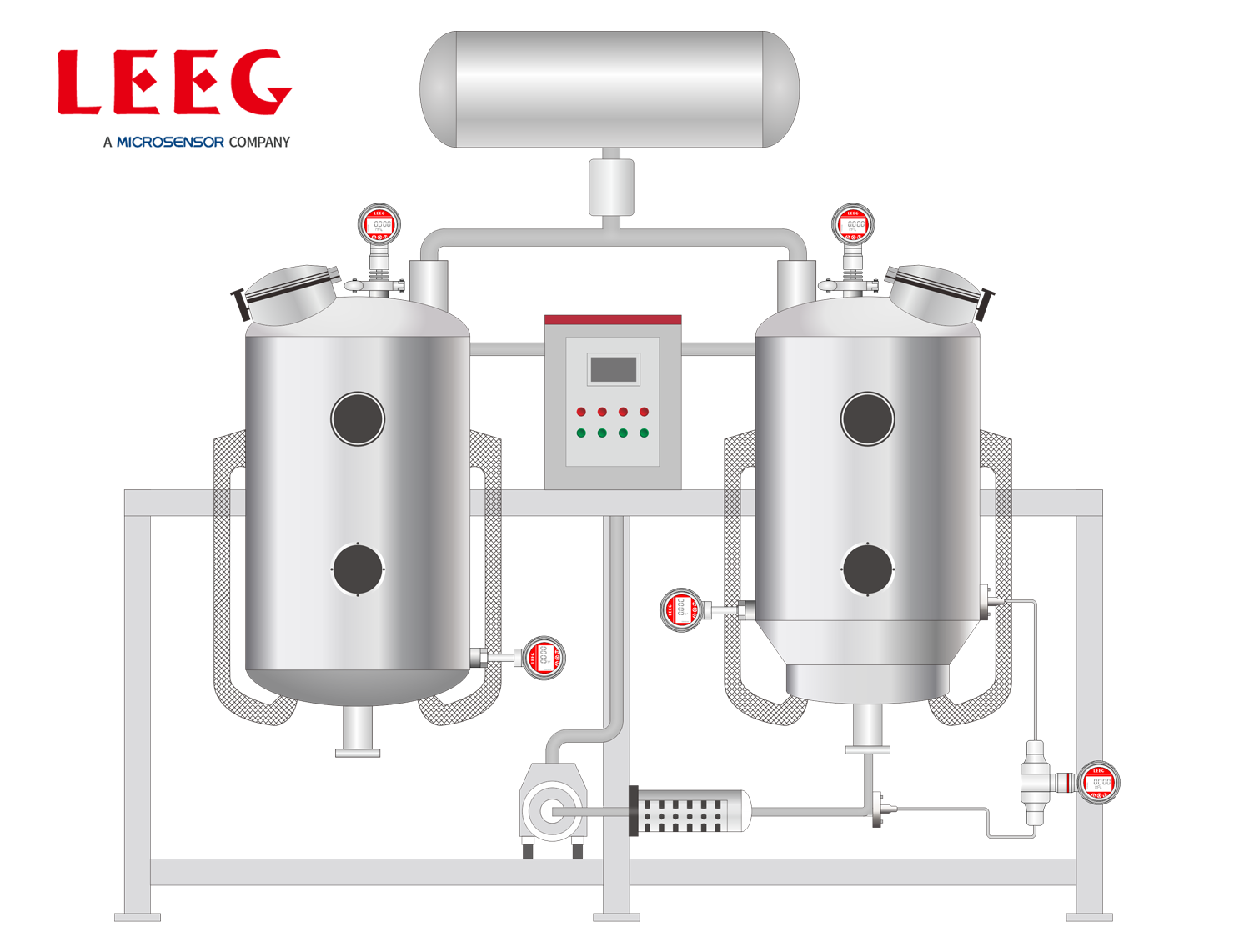

1. Organic acids, sugars and other chemical components in milk and juice will corrode the transmitter. At the same time, sediment will form in the storage tank, contaminating the sensor surface and affecting the measurement accuracy.

2. Transmitters in milk and juice storage tanks must meet strict hygiene standards to prevent any microorganisms or foreign matter from contaminating food, and sensors need to be cleaned and disinfected frequently.

3. The viscosity and density of juice and milk will change with temperature and composition, affecting the measurement accuracy of the transmitter, especially in level and flow measurement.

4. The storage tank structure is complex, and some installation locations of the transmitter are not conducive to accurate measurement (such as dead angles, strong stirring locations, etc.), which may lead to unstable measurement data.

Solution Advantages:

1. The hygienic pressure transmitter is made of food-grade stainless steel 316L, which is effectively anti-corrosive.

2. The transmitter complies with EHEDG (European Hygienic Design Equipment Standard) or 3A sanitary standard to ensure no dead corners and easy cleaning.

3. The Mono-Si differential pressure and level transmitter accurately measures low density and low viscosity changes and regularly adjusts the measurement parameters.

4. Optimize the installation position and use intelligent algorithms to compensate for the measurement errors caused by the position to improve data infallibility.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD