Application challenges

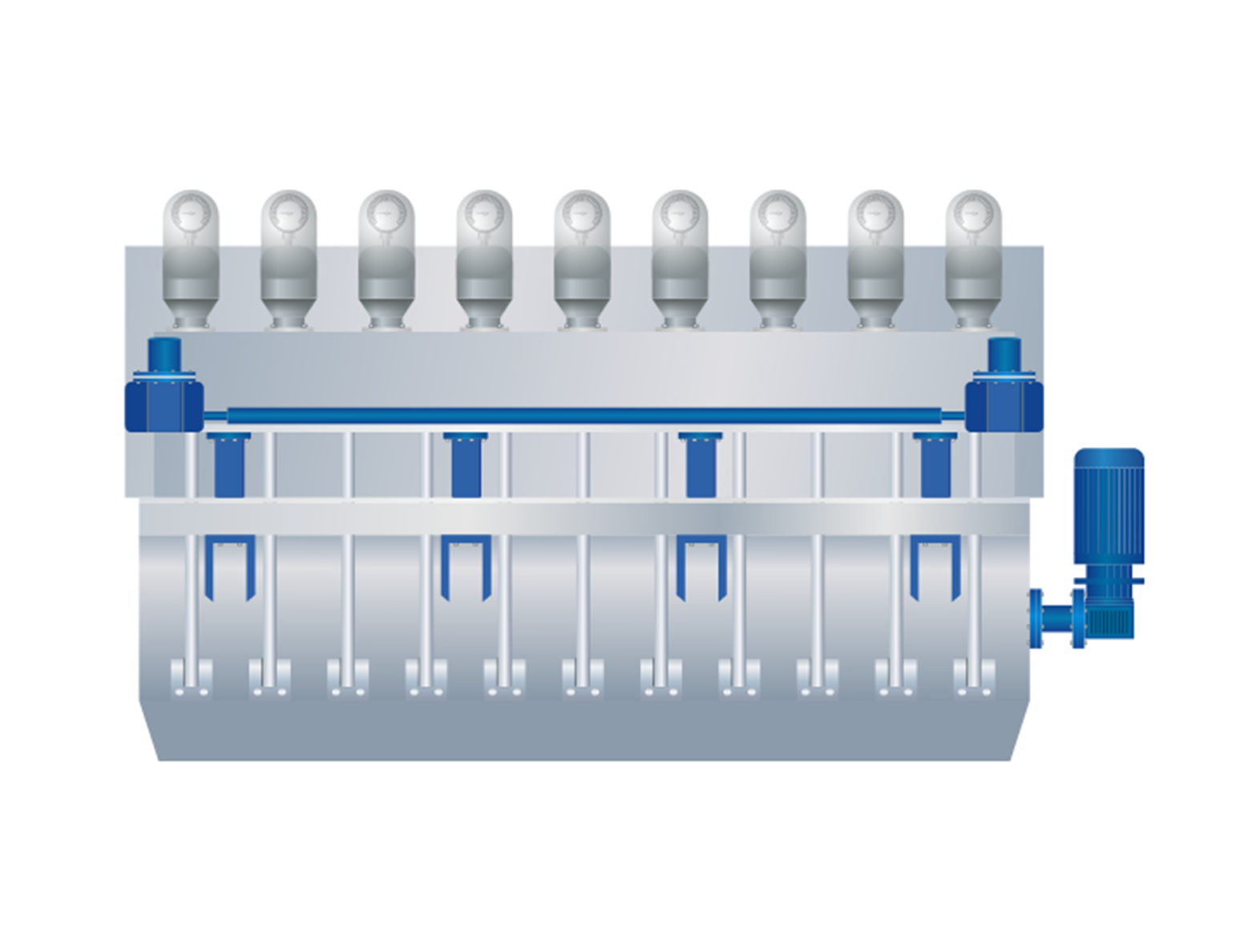

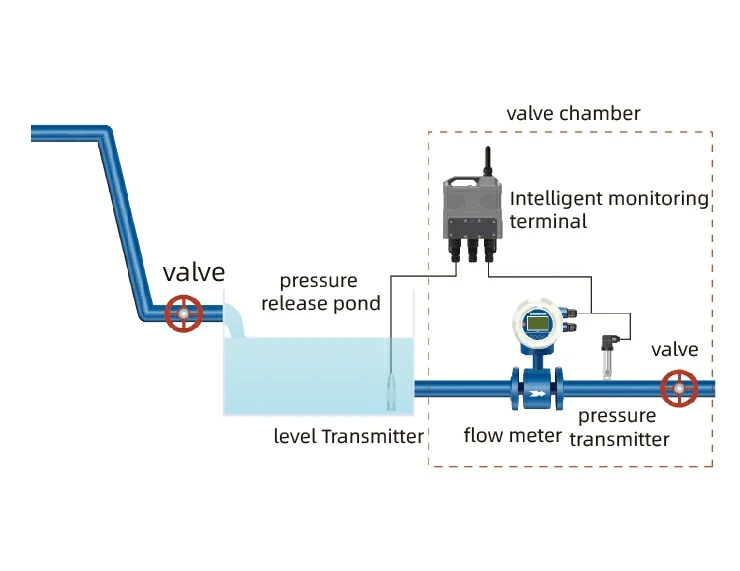

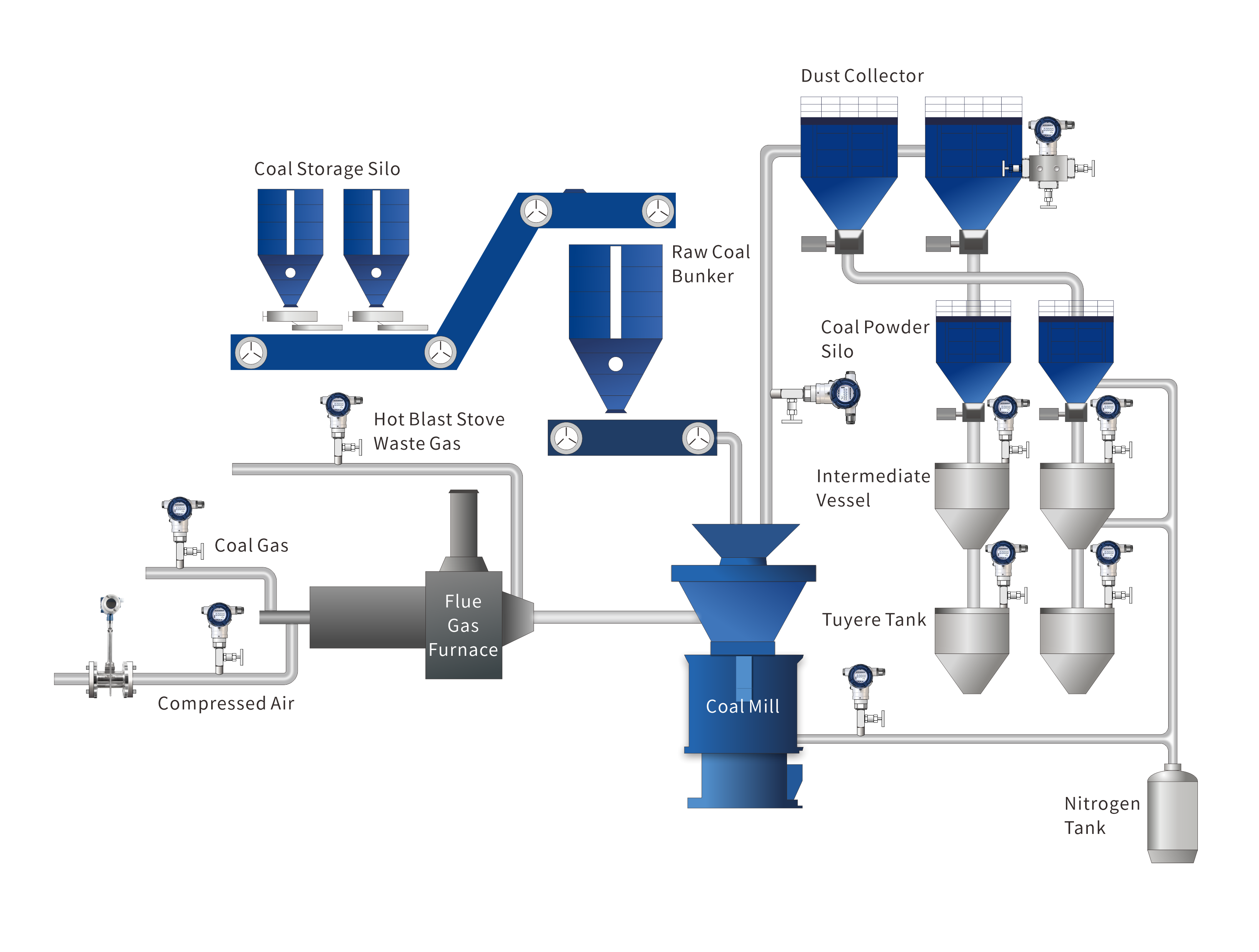

1. The headbox necessitates precise slurry flow rate and pressure management to achieve consistent distribution of paper quality.

2. Solid particles and fibers in the slurry might cause clogging and abrasion, reducing flow measurement accuracy.

3. The corrosive headbox slurry necessitates strong material corrosion resistance.

4. Environmental variables can have an impact on measurement stability and reliability in the headbox site.

Solution advantages

1. With high-accuracy sensors and fast response capabilities, it can monitor the flow and pressure of the slurry in real time to ensure uniform distribution of the slurry.

2. Anti-clogging construction, self-cleaning function, and wear-resistant materials ensure stable measurement under non-homogeneous slurry conditions.

3. Corrosion-resistant materials (such as stainless steel, Hastelloy, etc.) and special coatings can extend the service life of the equipment.

4. High-stability materials and compensation tech can still provide reliable measurements even under different conditions.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD