Due to the limited availability of conventional energy sources and growing environmental concerns, new energy sources are gaining increasing attention worldwide under environmentally friendly and renewable characteristics. The new energy industry involves wind power generation, new energy vehicles, photovoltaic power generation and so on. The development and utilization of renewable energy can obtain significant economic and environmental benefits.

Micro Sensor provides professional monitoring equipment for the stable operation of wind power generation, lithium batteries and other renewable energy industry monitoring scenarios.

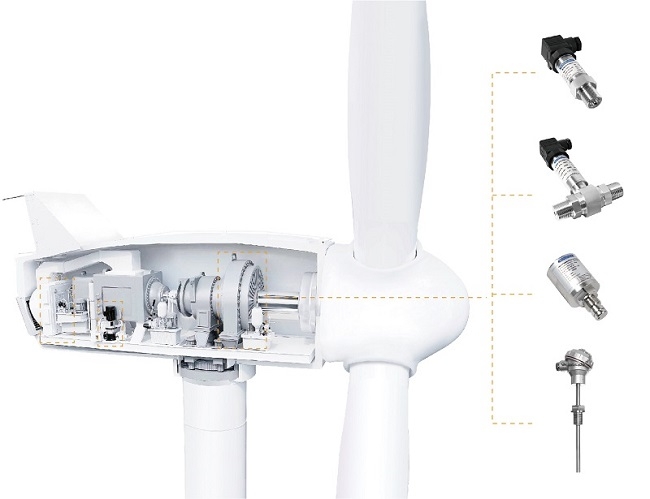

Wind Turbines

Wind turbines require a control system to optimize the orientation of the turbine in the wind (yaw control) and adjust the blades' angle (pitch control). The control system is accomplished through a cylinder system based on hydraulic principles. Pressure sensors play an essential role.

In a high-intensity working environment, monitoring equipment on wind turbines has the following challenges:

1. The harsh working environment requires the measurement products to be stable and durable.

2. The sensor needs to be able to withstand temperature changes and resist high vibration.

3. It also should be compatible with hydraulic fluid media.

Micro Sensor provides transmitters and sensors for data monitoring of wind turbines:

1. MPM4511 Pressure Transmitter

| • Range: 0bar ~ 16bar…1000bar • Stainless steel one-piece structure, no leakage • Micro-fused technology, High temperature resistance, shock resistance • Compact structure and cost-efficient • Wide working temperature range |

2. MDM491 Differential Pressure Transmitter

| • Range: 0mbar ~ 350mbar…20bar • All stainless steel structure design, small size and lightweight, install easily • Welded structure, full-sealed, enclosure protection IP65 • Diffused silicon piezoresistive differential pressure sensor with stainless steel 316L isolation diaphragm • Temperature compensation and aging screening make stable performance • Connector-type can adjust zero point and full scale externally |

3. WZ Temperature Sensor

| • Range: -200℃~ 0℃…1300℃ • Small size, easy to install • The sensor is in contact with the measured medium, with high reliabilit • The material of the part in contact with the medium is corrosion resistant • Diversified products can be provided • Explosion-proof certification Exd Ⅱ C T6 Gb • A variety of indexing numbers are optional |

4. MDM7000 Intelligent Differential Pressure Transmitter

| • Range: 60mbar~ 100bar • Accuracy: ±0.075%,±0.1%,±0.2%URL • Long-term stability: ±0.2%SPAN/5years • Working temperature: -40°C~85°C • Media temperature: -45℃~105℃ • Output signal: 4mA~20mA DC+HART, Modbus-RTU/RS485 • Power supply: 10.5V/16.5V~55V DC • Protection rating: IP67 • Certificate: NEPSI/NEPSI/CSA/CE/RoHS/IP67/HART |

5. MDM291 Differential Pressure Sensor

| • Range: 0bar~0.35bar…20bar • No O-rings, all welding construction, • Possible for various fliud media • Stainless steel 316L • High static pressure 20MPa • Wide temperature compensation: 0℃ ~70℃ • Pressure port (optional) • 2 times overpressure |

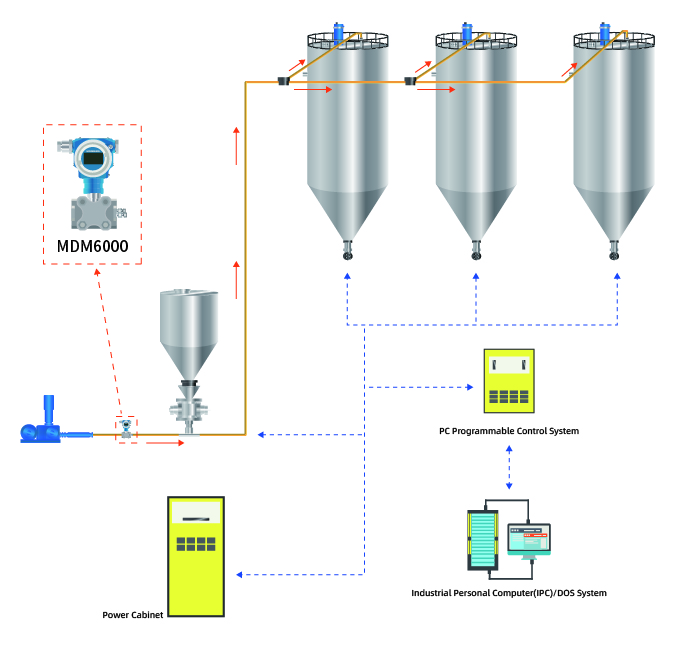

Pneumatic Conveying System in Lithium Battery

The production of positive and negative electrode materials for lithium batteries requires powder pneumatic conveying. It transports solid powder or granules by gas energy in a sealed pipeline. The pipeline is prone to material blockage when transporting materials with large particles, high viscosity, and poor fluidity.

When the pipeline pressure is abnormal, the pressure transmitters installed in sections on the delivery pipeline can give an alarm in time. Locating abnormal points facilitates timely repair of abnormal material blocking and ensures normal production.

In such a working environment, monitoring equipment is required to meet the following challenges:

1. The product requires sensitive response, accurate measurement, and timely data reporting.

2. Equipment maintenance is inconvenient, so the requirements for product stability are high.

3. Product solutions with complete certification and qualification are required.

Micro Sensor's pressure transmitters, temperature transmitters and flow meters provide professional monitoring solutions for lithium battery pneumatic conveying systems.

1. MDM7000 Intelligent Differential Pressure Transmitter

| • Range: 60bar ~ 100bar • Accuracy: ±0.075%,±0.1%, ±0.2%URL • Long-term stability: ±0.2%SPAN/5years • Working temperature: -40°C~85°C • Media temperature: -45℃~105℃ • Output signal: 4mA~20mA DC+HART, Modbus-RTU/RS485 • Power supply: 10.5V/16.5V~55V DC • Protection rating: IP67 • Certificate: NEPSI/NEPSI/CSA/CE/RoHS/IP67/HART |

2. WZ Temperature Sensor

| • Media temperature: -200℃~ 500℃ • Power supply: 10V~30V DC 15V~30V DC • Output signal: 4mA~20mA DC, RS485, HART • Accuracy: ±1.0%FS • Insulation Resistance: ≥ 20MΩ@500VDC • Circuit working temperature: -10℃~80℃ • Display meter temperature: -10℃~60℃ • Protection Class of Housing: IP65 • Small size, easy to install • Stainless steel, corrosion resistant |

3. MPM489 ATEX Pressure Transmitter

| • Range: -1bar…0mbar ~ 100mbar…1000bar • Accuracy: ±0.25%FS, ±0.5%FS, ±1%FS • Overpressure: 2 times FS or 1100bar (minimum value is valid) • Long-term Stability: ±0.3%FS/year • Vibration 10g, 55Hz ~ 2000Hz • Shock 100g, 11ms • Protection Rating IP65 • Certificate: NEPSI/ATEX/CE/RoHS/CCS |

Micro Sensor will continue to explore new energy industry applications and innovate products. Meanwhile, we are committed to providing professional monitoring equipment and solutions for more industries.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD