Today, I will introduce you to the last of these three indicators - pressure repeatability!

Definition of Repeatability

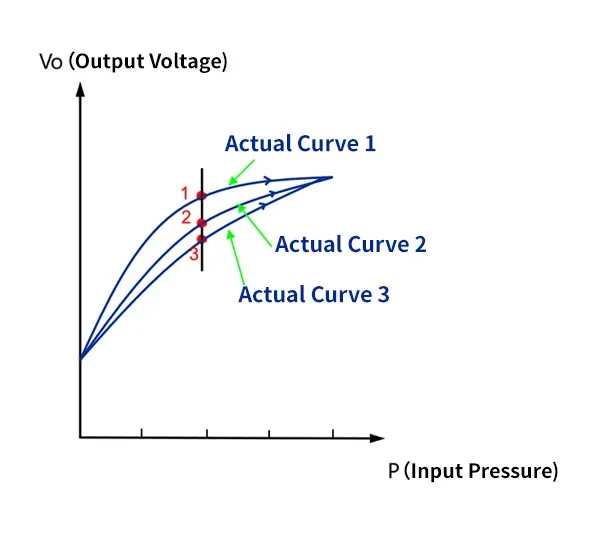

First of all, what is repeatability? The degree of inconsistency of the characteristic curves is obtained when the input quantity of the pressure sensor changes continuously many times in the same direction.

The more overlapping the output characteristic curves tested under the same input conditions, the better the repeatability and the smaller the error is.

Cause of Repeatability

However, the repeatability is easily affected by many factors and produces deviations, which are determined by the chip itself to the greatest extent, and then by the packaging process, such as wear, clearance, looseness, and internal friction of components in the process of sensor packaging, dust accumulation, and drift, etc.

Measuring Principle of Repeatability

How to measure the repeatability of the sensor? That requires multiple consecutive measurements of the same measured sensor under the same measurement method, observer, location of measuring instrument, conditions of use, and repetition within a short period of time.

Measuring Method

Under the specified conditions, apply a pre-pressure of no less than 3 times to the sensor, so that the pressure of the tested sensor rises to the upper limit of the measurement, and after the pressure is stabilized, the pressure is reduced and returned to zero.

Then, within the full-scale range including the upper and lower limits of the sensor measurement, select 6 to 11 test points evenly distributed, measure the sensor output corresponding to the input pressure point, and repeat the rise and fall 3 or more times.

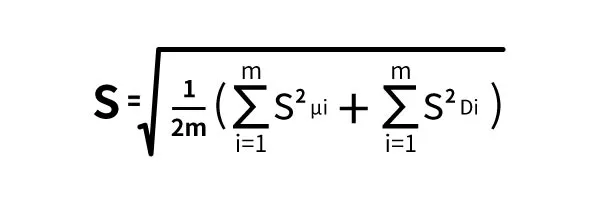

The sample standard deviation S of the sensor over the entire measurement range is calculated by the following formula:

where:

m——the number of calibration points;

Sui——Standard deviation of positive stroke samples;

SDi - standard deviation of inverse stroke samples

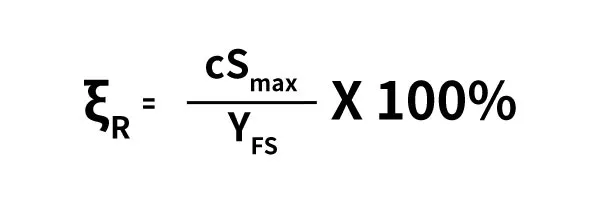

Repeatability ξR is calculated by the following formula:

where:

c——Inclusion factor, c=t0.95;

Smax - the largest sample standard deviation,

The largest one can be selected from the estimates S of the 2m standard deviations of the m calibration points; the consistency between the obtained results can lead to the repeatability!

Note: Under the above conditions, the consistency between the measured results is repeatability. The repeatability value of each product is slightly different, and the repeatability index of Mcro Sensor is less than or equal to 0.075% FS, which means that the repeatability index of the product meets the standard.

Optimization Measures

So how does Micro Sensor Lab ensure excellent sensor repeatability?

International standard chip, laser trimming compensation.

In the packaging, a certain degree of stress relief process is performed after the adhesive process is completed to ensure that the stress after chip bonding is minimized.

The product packaging structure is ingeniously designed to ensure a sufficiently small amount of oil.

Unique diaphragm structure design.

Well, that's all for today. What else do you want to know about pressure sensors? leave us a comment below~ see you next time!

Copyright © 2026 MICRO SENSOR CO., LTD

Copyright © 2026 MICRO SENSOR CO., LTD