With the concept of new infrastructure, a new round of technological and industrial reforms centered on the Internet will deepen, and the changes and innovations brought by people's production methods and lifestyles will become more revolutionary.

The development of the world's petrochemical industry also needs to be more intelligent, which is not only dictated by the law of industrial development but also to respond to resource shortages, imbalances in supply and demand, rising production costs, and the urgent need for industrial integration.

In recent years, the development of our country's petroleum and chemical industries has gradually entered the track of transformation, upgrading, and accelerated development. With the vigorous advancement of the construction of "smart oilfields", "smart drilling", "smart pipelines", "smart refineries", and "smart chemical plants", the large-scale, highly automated, intelligent, and informatized production equipment has become an inevitable trend, the automation instrument that matches with it also ushered in a broader space for development.

Micro Sensor has been deeply involved in many intelligent upgrade projects in petrochemical-related industries and owns a wide range of applications in this field. We have accumulated profound experience and can provide customers with customized products and solutions.

1. Oil/Gas Storage and Transportation System Monitoring

Oil storage tanks and oil/gas pipelines are necessary equipment for oil/gas storage and transportation, covering multiple links in the entire industry and having the most extensive applications.

Oil products go through several rounds of storage, transportation, and loading and unloading processes from mining to finished products delivered to end-users. Among them, changes in temperature, pressure, liquid level, and volume in storage

tanks and pipelines have an impact on inventory and safety management.

Based on this demand, Micro Sensor designed and manufactured many products such as the MDM3051S differential pressure transmitter, MPM489W level transmitter, MPM480 pressure transmitter, MTM4831 temperature transmitter, etc., to monitor the state of oil storage tanks and pipelines. These products help change the traditional methods of manual inspection and analysis, realize automatic and real-time monitoring, and provide accurate data basis for production operation and management decisions.

Apply MPM426W level transmitter, MPM489W level transmitter, MDM3051S differential pressure transmitter, and other products to measure and monitor the oil level of the oil storage tanks in real-time.

Apply MTM4831 temperature transmitter and other products to monitor the temperature condition in the tank and pipeline in real-time to prevent the temperature from exceeding the safe value and greatly avoid the occurrence of safety accidents.

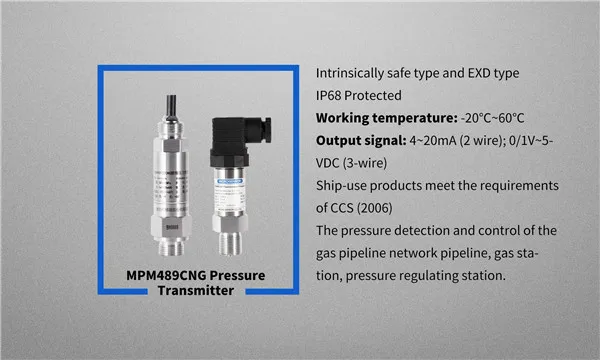

Apply products such as MPM480 pressure transmitter, MPM483 pressure transmitter, MPM489 pressure transmitter, and other products to measure and monitor the pressure of oil/gas pipelines, monitor the pressure of the pipeline in real-time, adjust the pressure of the transmission and distribution, and monitor the leakage of the pipeline.

2. Oil and Gas Online Monitoring System and Recovery Device in Gas Station

Oil products are highly volatile. During storage and transportation, changes in environmental factors can easily cause oil and gas to volatilize into the atmosphere, causing a series of problems such as potential safety hazards, environmental pollution, energy waste, economic losses, etc.

Oil and gas pollution discharged from gas stations mainly occurs in the parts of tank trucks unloading oil to underground storage tanks, gas dispensers refueling to automobile tanks, and "small breaths" of underground storage tanks.

(1) Oil and Gas Online Monitoring System

Apply Micro Sensor MDM3051S differential pressure transmitter in the oil and gas pipeline loop to measure the hydraulic resistance pressure of the oil and gas pipeline. According to the real-time data of the negative pressure value, monitor the oil and gas recovery of the oil tank and the automobile to prevent oil and gas leakage.

(2) Oil and Gas Recovery Device

Generally, the recovered oil and gas will be sucked into the storage tank, and then processed by the recovery device for condensation and other treatments. Apply MPM430 pressure transmitter and MPM489 pressure transmitter to monitor the pressure of oil and gas storage tanks in real-time, and use the pressure value as the start-stop input signal of the recovery processing device.

3. Oilfield Water Injection Measurement and Control

Oilfield water injection is one of the important links in oilfield development currently. After the oil field was put into development, the pressure of the oil layer continued to drop, the output of the oil well was greatly reduced, and a large amount of dead oil remained underground, which was difficult to extract. In order to maintain or increase the oil layer pressure and obtain a higher recovery rate, high-pressure water injection must be used.

The water injection volume is one of the core parameters of water injection in oilfields, so the measurement and control of water injection in oilfields are very important.

In the past, oilfield water injection used traditional mechanical water meters, Magnetoelectric or vortex flow meters, and other products. Since these products have flow blocking parts in the middle, they are easy to block, which will lead to a large maintenance workload. The principle of the electromagnetic flowmeter avoids such problems well, so it has a better application prospect in the water injection link.

Micro Sensor MFE600E series of high-pressure electromagnetic flowmeters can be well used in oilfield water injection metering applications.

More detailed products and solutions for pressure measuring and control in the petrochemical industry, don’t hesitate to contact us via sales@microsensor.cn our sales engineer will reply you within 24 hours.

Previous Posts: Oil and Gas Recovery with Differential Pressure Transmitter at Oil Station

Next Chapter: How to Regulate the Pressure Intelligently in Natural Gas Pipeline Network System?

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD