The installation position of the pressure transmitter on the process pipe is related to the measured medium. In order to obtain better measurement results, the following should be considered:

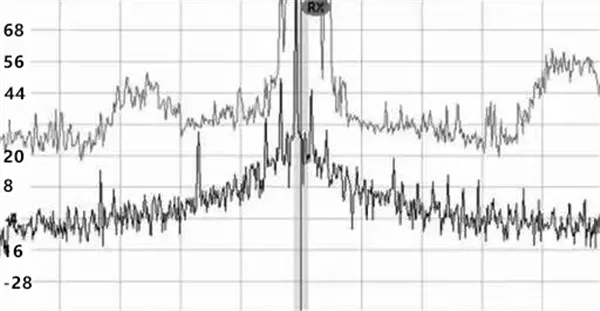

1. First, check whether there is signal interference around the pressure transmitter, if any, try to eliminate it, or connect the sensor shield wire to the metal casing as much as possible to enhance the anti-interference ability.

2. Clean the mounting holes regularly to ensure cleanness. Prevent the pressure transmitter from coming into contact with corrosive or overheated media.

3. When freezing occurs in winter, the pressure transmitter installed outside must adopt anti-freezing measures to prevent the liquid in the pressure inlet from volume expanding due to freezing, resulting in damage to the pressure sensor.

4. Prevent dross from depositing in the pipe.

5. When measuring liquid pressure, the pressure tap should be opened on the side of the process pipe to avoid sedimentation;

6. When measuring gas pressure, the pressure tap should be open at the top of the process pipe, and the pressure transmitter should also be installed in the upper part of the process pipe so that the accumulated liquid is easily injected into the process pipe.

7. The breath tube should be installed in a place with small temperature fluctuations.

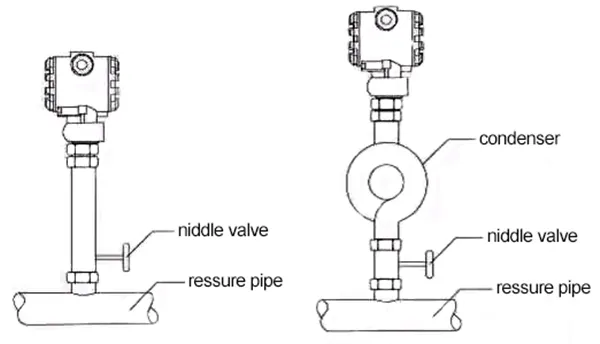

8. When measuring steam or other high-temperature media, it is necessary to add a condenser such as a buffer tube (coil) and the operating temperature of the pressure transmitter should not exceed the limit;

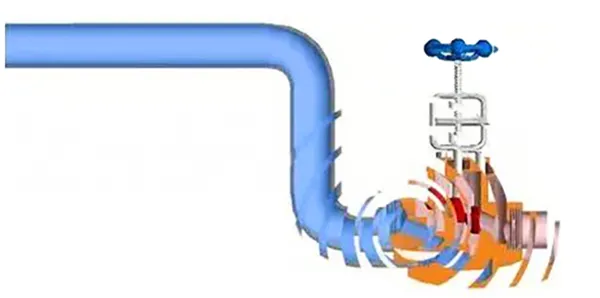

9. When measuring the liquid pressure, the installation position of the pressure transmitter should avoid the impact of liquid (water hammer phenomenon), so as to avoid damage caused by overpressure of the pressure sensor;

High-speed condensate collision in the pipeline forms a water hammer

10. When wiring, pass the cable through the waterproof joint or the coil tube and fasten the seal nut to prevent rainwater from leaking into the pressure transmitter housing through the cable.

For more information, feel free to contact us via sales@microsensor.cn or leave a message here.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD