Industry Prospects

With the increasing demand for the new energy vehicle market, various supply chain industries have surged. Among them, the lithium cell, as one of the most important components, accounts for 40%-50% of the overall cost.

In the production of lithium battery, the cathode material accounts for approximately 36% of the overall cell cost. Therefore, the demand for cathode materials in the market has witnessed an explosive growth. The efficient operation of the cathode material production line heavily relies on the support of various flowmeters.

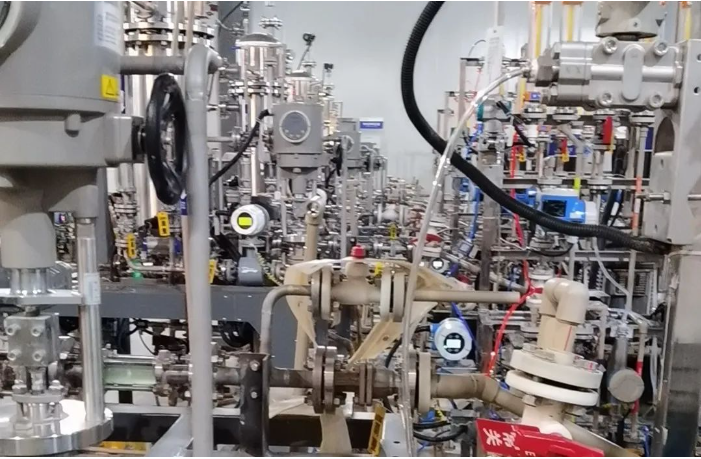

Industry Applications

Taking the production process of ternary precursor for lithium battery cathode material as an example:

• Ingredients Process

Preparation of raw material solution from waste batteries treatment

Leaching workshop: The leaching workshop requires the application of electromagnetic flowmeters to accurately measure the flow of sulfate solution, concentrated sulfuric acid, acid-base tank transfer, leaching reactor discharge, and slurry. This enables controlling and monitoring of the entire reaction process, ensuring the quality of the final product.

Extraction workshop: The extraction workshop necessitates accurate process control of flow in acid-base circulation tank, clarification pool, extraction solution tank, and pure water analytical solution. This is done to synchronize with the production process and facilitate the generation of the final raw material solution.

Preparation of raw material solution from purchased sulfate crystal

In the ingredients process, the level and flow of the metal dissolving tank (ingredients), cobalt liquid tank, metal solution tank, ammonia water tank, alkali liquor, and concentrated intermediate tank are monitored. Flowmeters are essential in this process, ensuring refined proportion of raw material.

• Synthesis Process

The synthesis process consists of three stages: synthesis reaction, precipitation treatment, and mother liquor treatment.

In these stages, the following components are crucial: reaction kettle, dilute alkali intermediate tank, pure water intermediate tank, ammonia water intermediate tank level, concentrated intermediate tank level, mother liquor tank/mother liquor buffer tank, washing and slurry formation. At each stage, flowmeters play a critical role in flow process control, ensuring accurate measurement and flow control.

Electromagnetic Flow Meter Applications

The cathode material of lithium iron phosphate (LiFePO4) cell mainly consists of raw materials such as lithium carbonate, phosphoric acid, and iron salt, which are processed through mixing, sintering, and ball milling techniques.

In this production process, electromagnetic flowmeters can serve several purposes:

• Measuring Raw Material Feed Flow

In the production process of LiFePO4 cell cathode material, refined proportion and accurate control of raw materials are essential.

Electromagnetic flowmeters can accurately measure the feed flow of various raw materials and provide feedback to the automatic control system for adjustments.

• Monitoring Reaction Liquid Flow

Raw materials should be mixed up with oxidizers, reducers, and other reactants before adding them to the reactor in the processes of sintering and ball milling of LiFePO4 cell cathode material.

Electromagnetic flowmeters can monitor the flow of the reaction liquid. This ensures the full mixing of the reactants, enhancing product quality and process efficiency.

• Controlling Wastewater Discharge

During the production process of LiFePO4 cell cathode materials, a certain amount of wastewater will be generated.

Electromagnetic flowmeters can monitor the real-time discharge volume of wastewater. This enables the rationalization of wastewater emissions and reducing environmental impact through an automated control system.

Thus, the lithium battery industry has high requirements for electromagnetic flowmeters as below:

• High-accuracy

Monitoring the real-time flow of the reaction liquid is essential during production. Therefore, electromagnetic flowmeters with high accuracy and stability are required to ensure the accuracy of measurement data.

• Corrosion-resistant

In the production process of LiFePO4 cell cathode material, various chemicals are involved, including acids, alkalis, and other highly corrosive media.

Therefore, the sensors and pipelines of the electromagnetic flowmeters shall be made of corrosion-resistant materials. This aims to ensure long-term stable operation.

• Anti-interference

Due to environmental noise and electromagnetic interference, electronic devices are easy to be disturbed, which can affect measurement accuracy.

Therefore, anti-interference technology shall be adopted to weaken the impact of external interference on measurements.

• Reliability

During the production process, electromagnetic flowmeters shall be operated with long-term stability.

Therefore, high reliability and durability are required to ensure long-term stable operation.

Recommended Flowmeter

Micro Sensor MFE600E Electromagnetic Flowmeter

| • Range: Diameter DN25~DN200; • Accuracy: ±0.2%FS; ±0.5%FS; • Operating temperature: -40°C~60°C; • Output: 4mA~20mA DC; Hart; Frequency, Pulse; RS485 (ModBus protocol) RS232 output; • Certifications: TS, CNEX, CE, CCS |

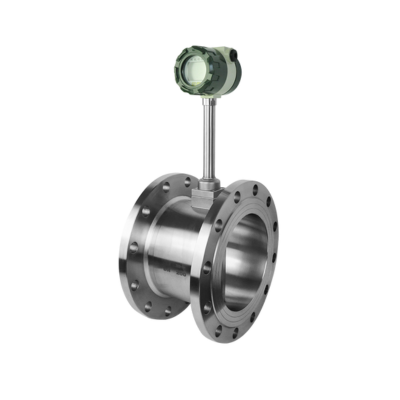

LUGB Vortex Flowmeter

| Vortex flowmeters play an important role in monitoring the liquid flow change during the preparation process of the cathode material. It will control the feeding rate reaction rate, and other key specifications, so as to control the material preparation process. This aims to ensure the stability and consistency of product quality. In addition, vortex flowmeters assist in flow control and proportion control. This aims to ensure accurate control of liquid components during the preparation process of the cathode material. Finally, the product quality and production efficiency will be improved. |

MFC608 Coriolis Mass Flowmeter

| Mass flowmeters are vital in measuring mass flow. The product has high accuracy, without the influence of medium density and temperature. Besides, multi-specification measurement will also be achieved. In the slurry process of the LiFePO4 cathode material production line, mass flowmeters are commonly used to measure the mass flow of the slurry. |

After more than ten years of development and improvement, China is now the world's largest lithium battery material and battery production base. The prospects for the lithium battery industry are very bright. Micro Senso sincerely welcomes customers and partners to explore a broader market with us!

Copyright © 2026 MICRO SENSOR CO., LTD

Copyright © 2026 MICRO SENSOR CO., LTD