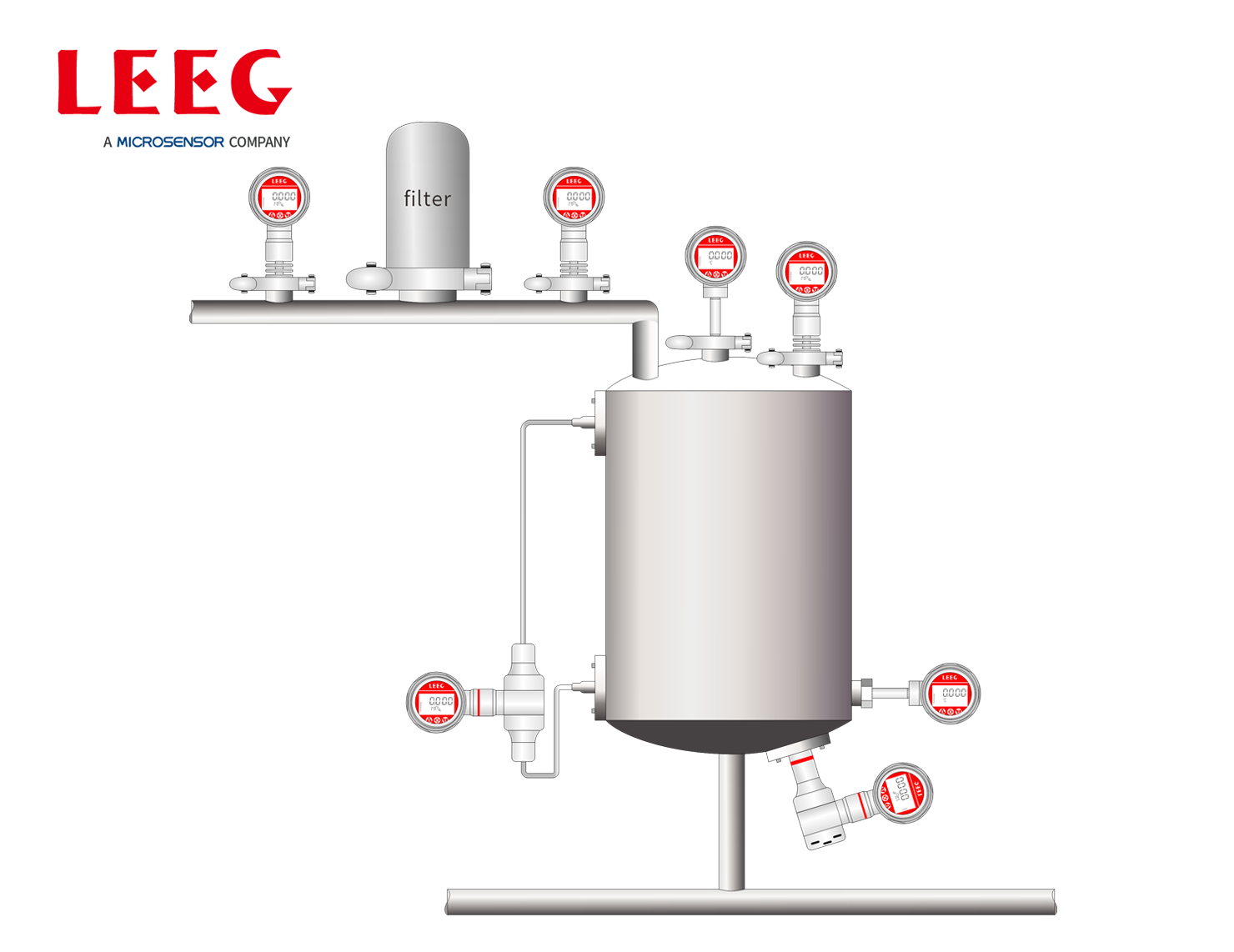

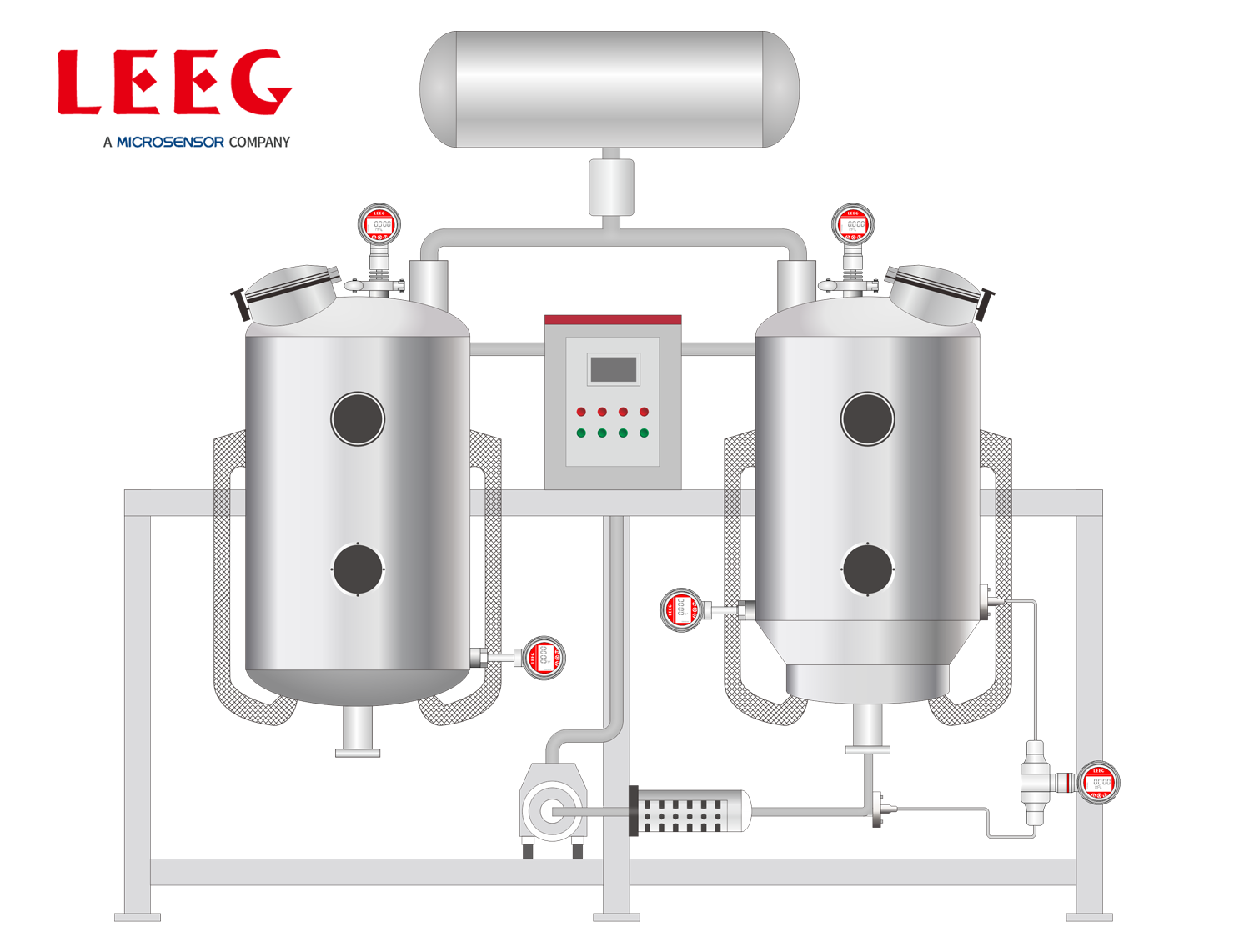

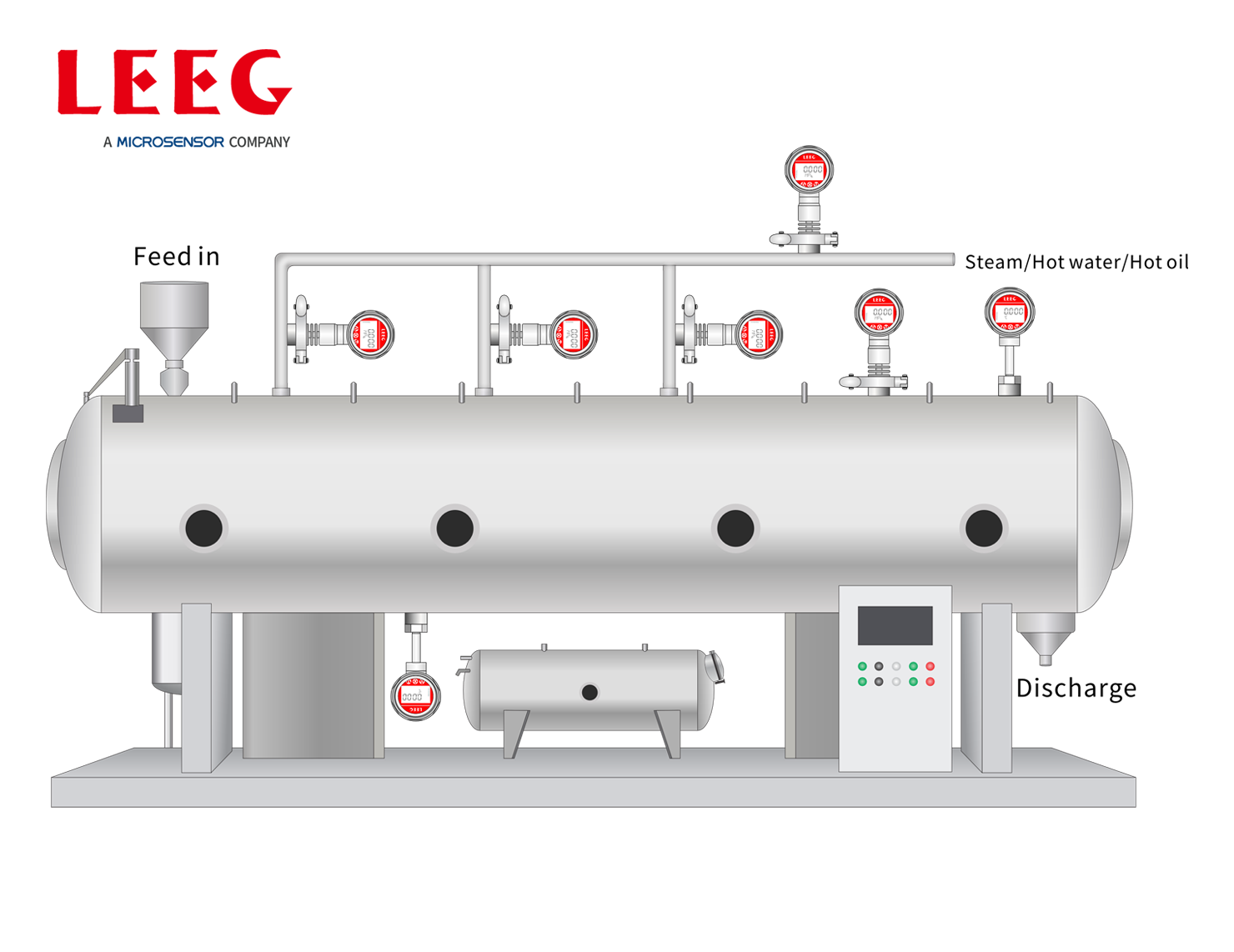

Application Challenges:

1. Reaction kettles usually involve high temperature and high-pressure conditions, especially in the pharmaceutical industry. Such conditions can cause transmitters to fail to operate properly or reduce accuracy.

2. The materials in the reaction kettle are often multiphase, including liquids, gases, suspended solids, and even high-viscosity fluids, which may fluctuate due to uneven media.

3. Reaction kettles are usually equipped with stirring devices, which may generate eddies and level fluctuations during stirring, resulting in unstable measuring data of level or pressure transmitters.

4. The temperature in the reaction kettle is usually uneven, especially during heating or cooling, the temperature gradient is obvious, which will cause inaccurate measurement data of the temperature sensor.

Solution Advantages:

1. LEEG hygienic pressure transmitter adopts high temperature and corrosion resistant 316 material and involves heat sink.

2. The Mono-Si sensor effectively reduces the influence of stirring and non-uniform media on the measurement, and performs data compensation through intelligent algorithms to optimize the measurement results in multi-phase materials.

3. The hygienic pressure transmitter is vibration-resistant. The test vibration effect is <0.1%, compliant with GB/T18271.3/IEC61298-3.

4. Multi-point temperature transmitter is available to measurer the temperature at different locations. Use temperature compensation technology to ensure the stability of measurement data at different temperatures.

Copyright © 2026 MICRO SENSOR CO., LTD

Copyright © 2026 MICRO SENSOR CO., LTD