Application Introduction

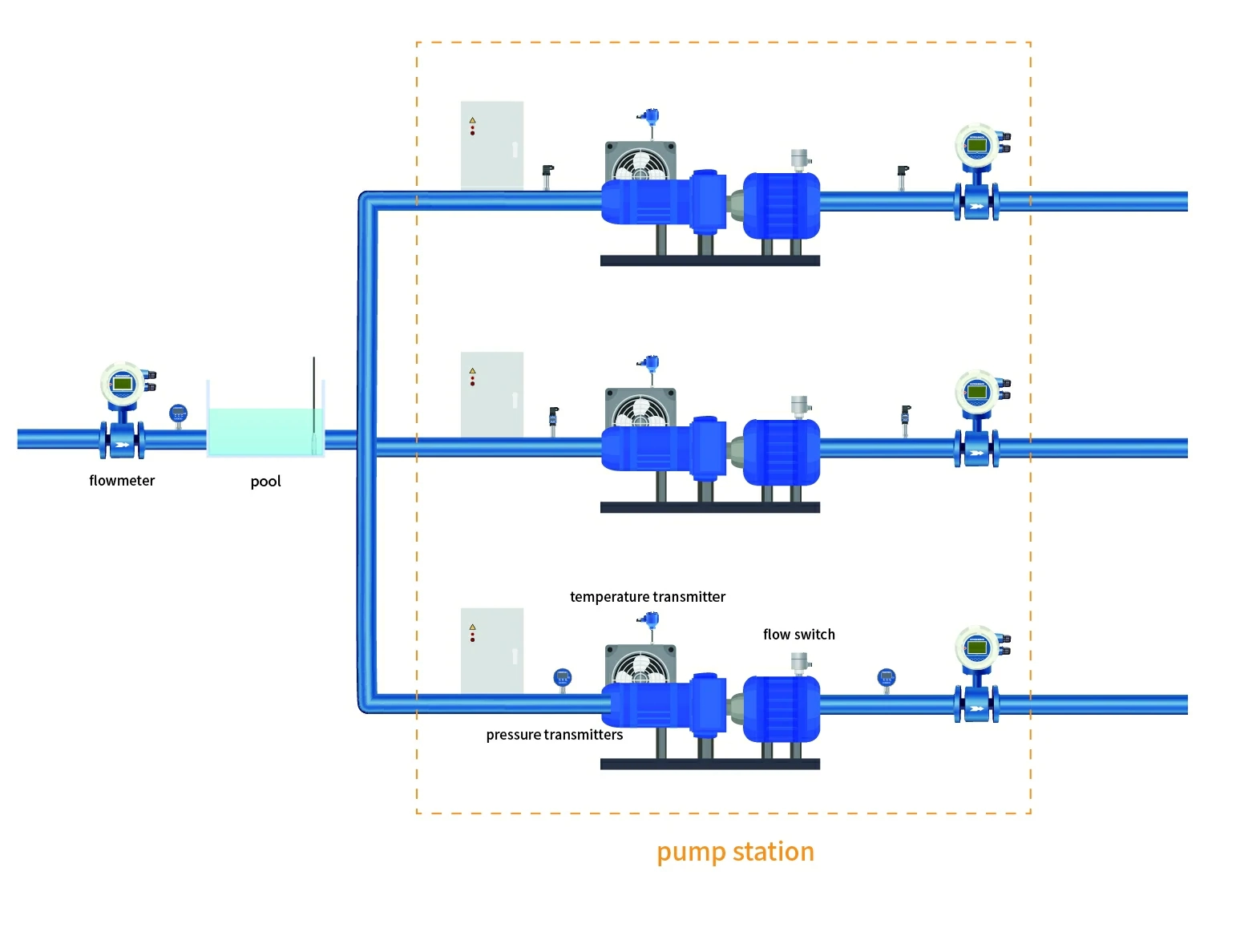

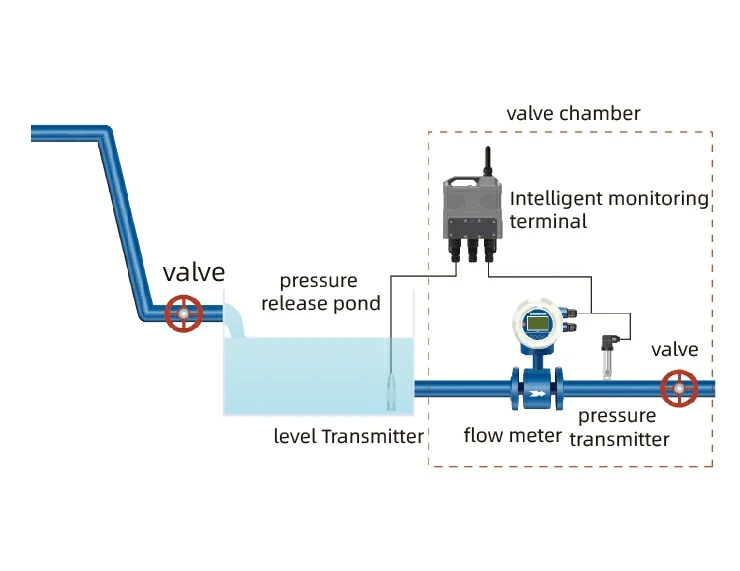

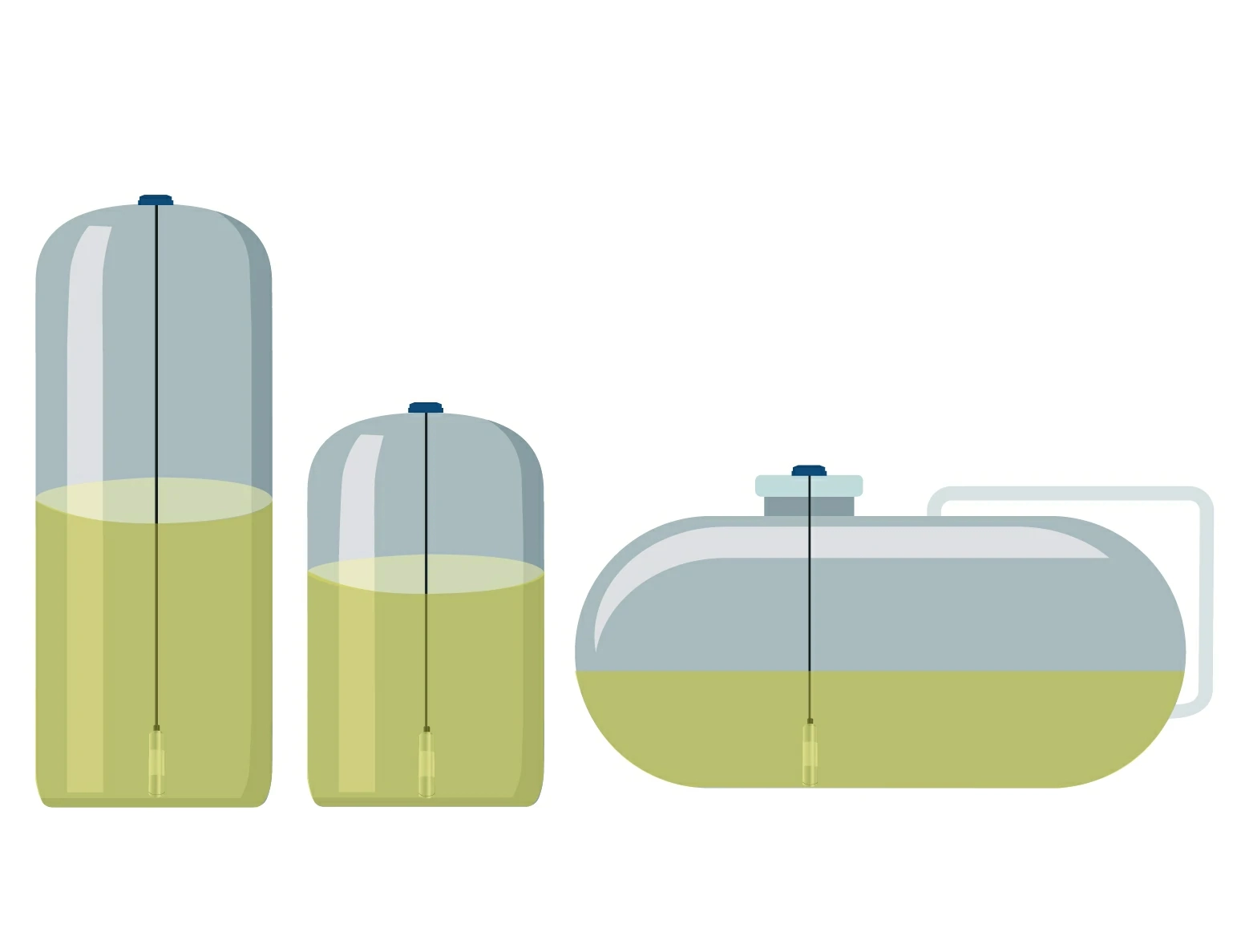

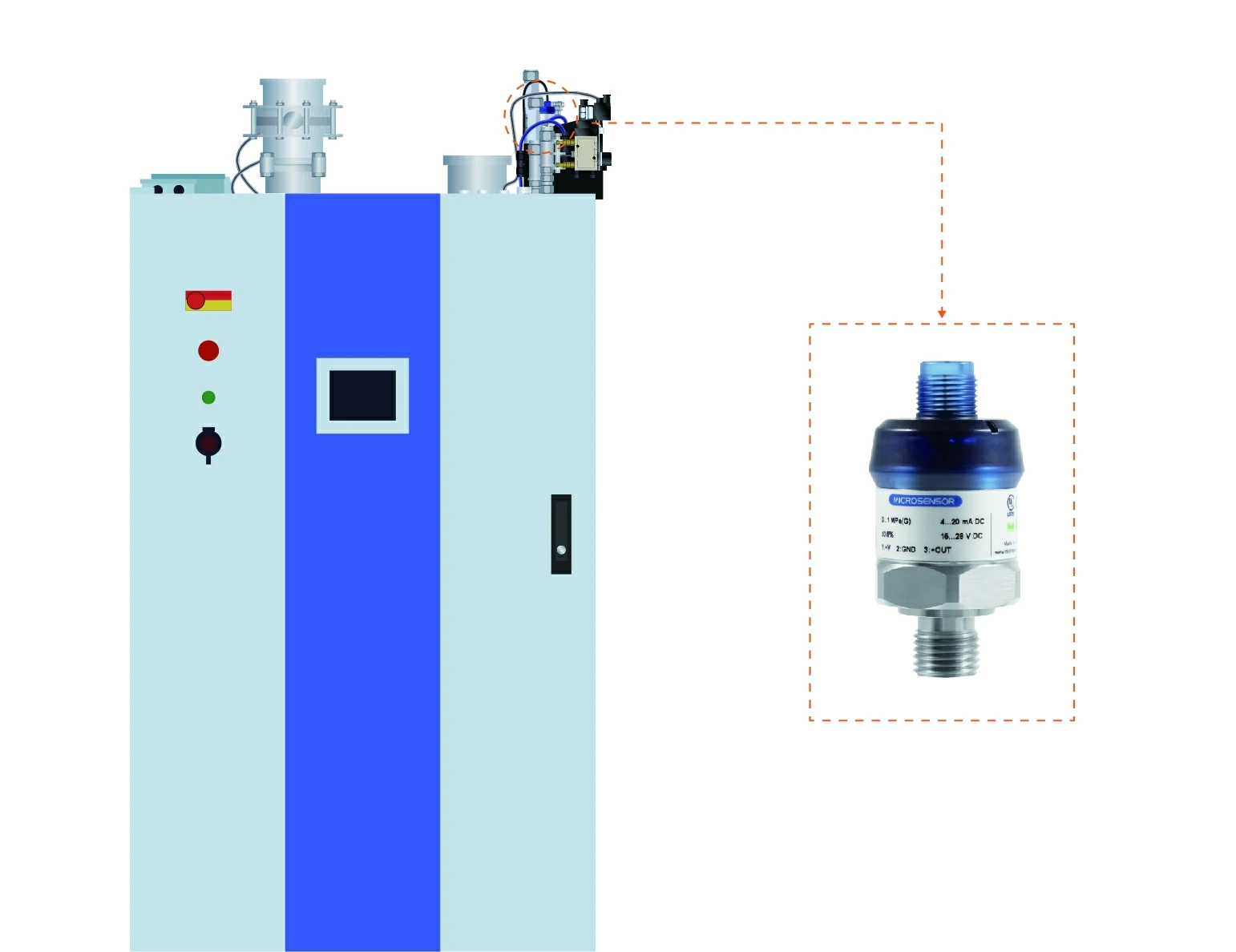

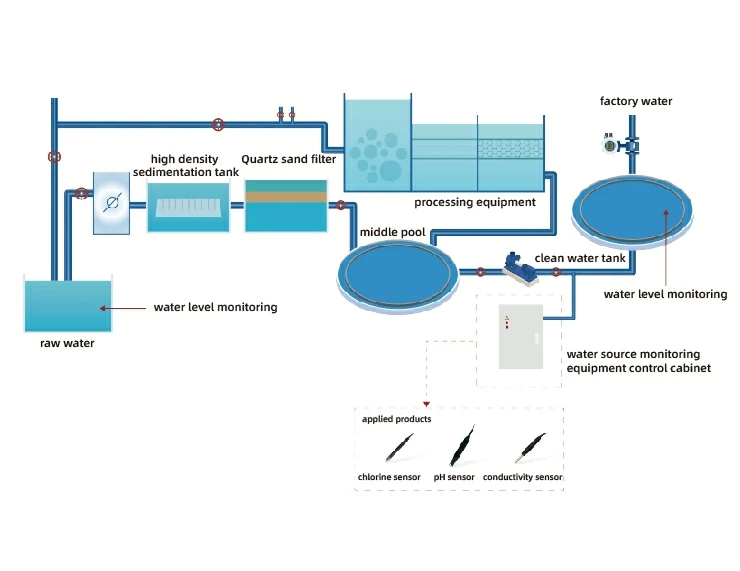

Irrigation and drainage pumping stations solve the problem of gravitational water diversion in irrigation areas, enabling cross-basin water transfer. MicroSensor provides real-time pressure and flow monitoring for inlet and outlet pipelines of these pumping stations, contributing to the accurate measurement of information-based irrigation areas and high-standard farmland construction.

Contact Engineer

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD