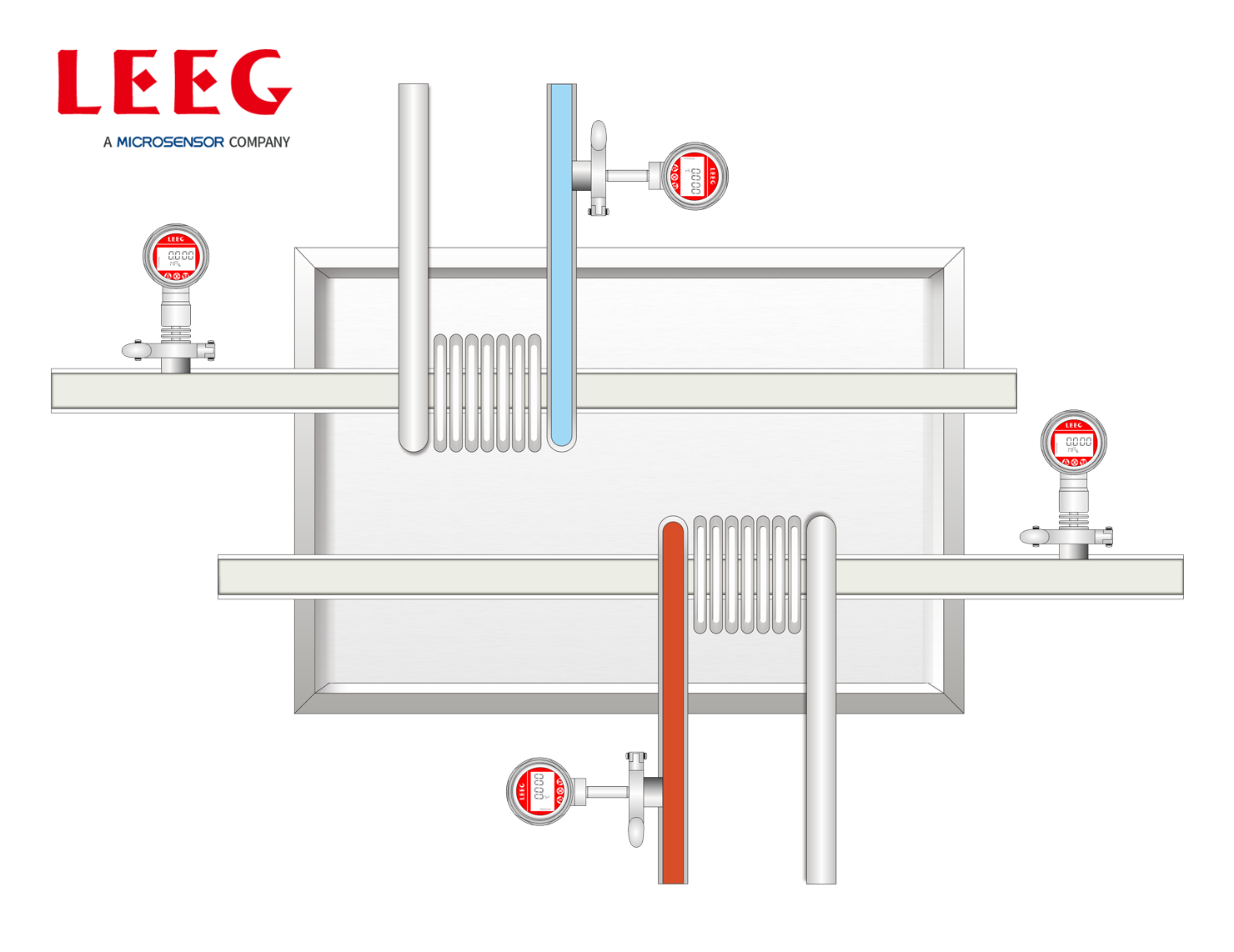

Application Challenges:

1. The frequent temperature fluctuations in preheaters and heat exchangers, especially during rapid heating and cooling processes, may result in unstable transmitter readings, affecting accuracy and control.

2. In acidic fruit juices, dairy products, or fermentation processes, the transmitters come into contact with corrosive media, impacting equipment lifespan and measurement accuracy.

3. Within the heat exchanger, food residues, dairy proteins, or other substances are prone to form contaminants or deposits on the sensor surfaces, leading to inaccurate measurements or even equipment failure.

4. Food processing facilities typically have complex electrical and mechanical equipment, which can generate strong electromagnetic interference, impacting transmission and leading to unstable measurements.

Solution Advantages:

1. Temperature compensation technology ensures the stability of measuring data under varying temperatures.

2. Made of food-grade stainless steel 316L to cope with corrosion from different media.

3. Certified by 3A and EHEDG, featuring a simple design that is easy to clean due to its non-clog, non-contamination, and dead-zone-free construction.

4. It adopts Mono-Si sensing technology with strong anti-interference ability. MODBUS, HART and other digital signal transmissions are available.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD