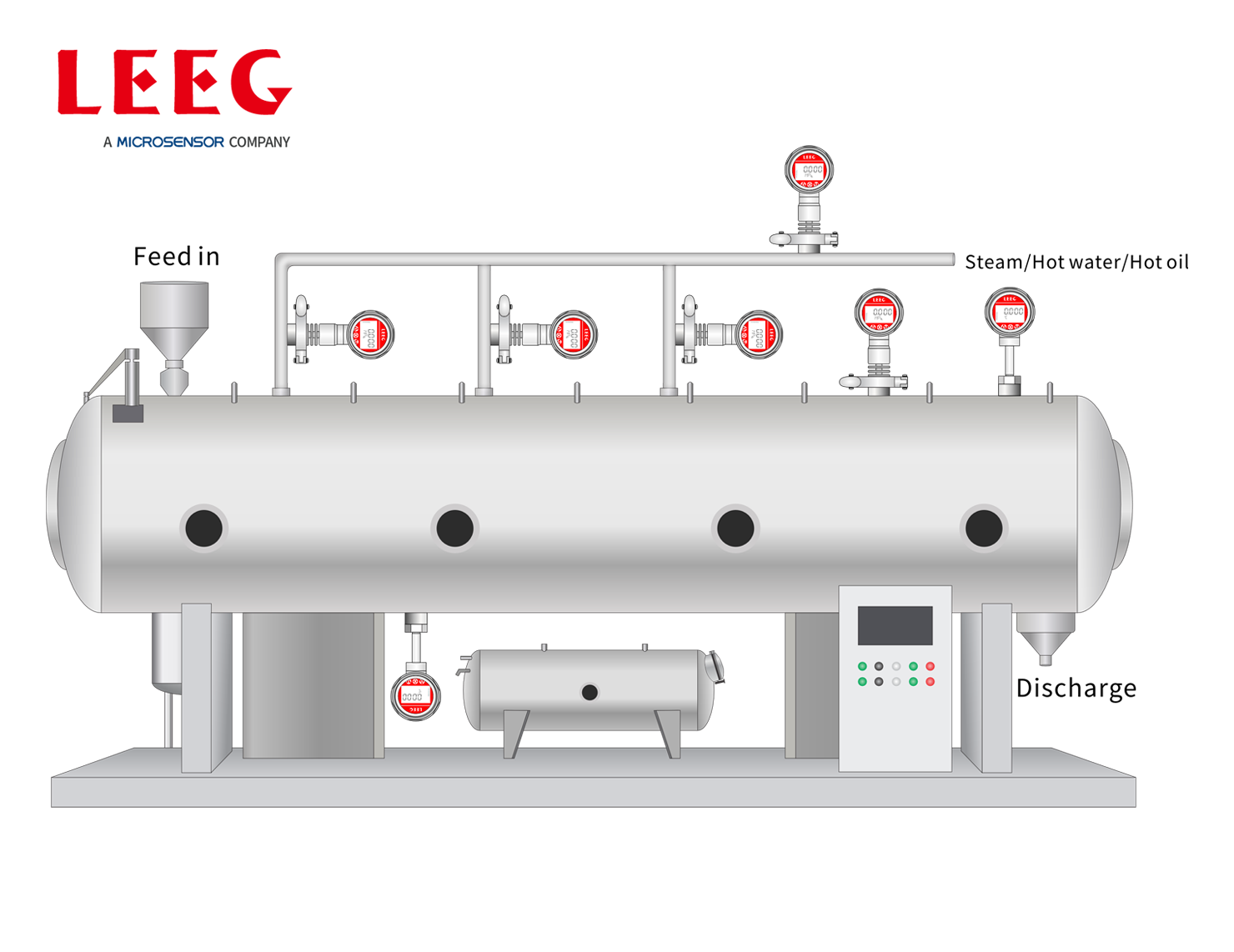

Application Challenges:

1. The heating area in the dryer and the area in direct contact with the material are usually in a high-temperature environment, which can easily damage the sensitive element of the transmitter and cause equipment failure.

2. During the drying process, especially when the humidity changes greatly, water vapor or condensed water enters the transmitter, which may cause short circuits, corrosion or signal abnormalities.

3. Some drying equipment (such as fluidized bed dryers or vibrating belt dryers) will generate mechanical vibrations and shocks during operation, which may cause the transmitter connection to loosen, damage, or even unstable measurements.

4. Electrical equipment inside the dryer or the external electromagnetic environment may generate electromagnetic interference, affecting the transmission of sensor signals.

Solution Advantages:

1. Temperature compensation technology ensures the stability of measuring data under varying temperatures.

2. Made of food-grade stainless steel 316L to cope with corrosion from different media.

3. Certified by 3A and EHEDG, featuring a simple design that is easy to clean due to its non-clog, non-contamination, and dead-zone-free construction.

4. It adopts Mono-Si sensing technology with strong anti-interference ability. MODBUS, HART and other digital signal transmissions are available.

Copyright © 2025 MICRO SENSOR CO., LTD

Copyright © 2025 MICRO SENSOR CO., LTD