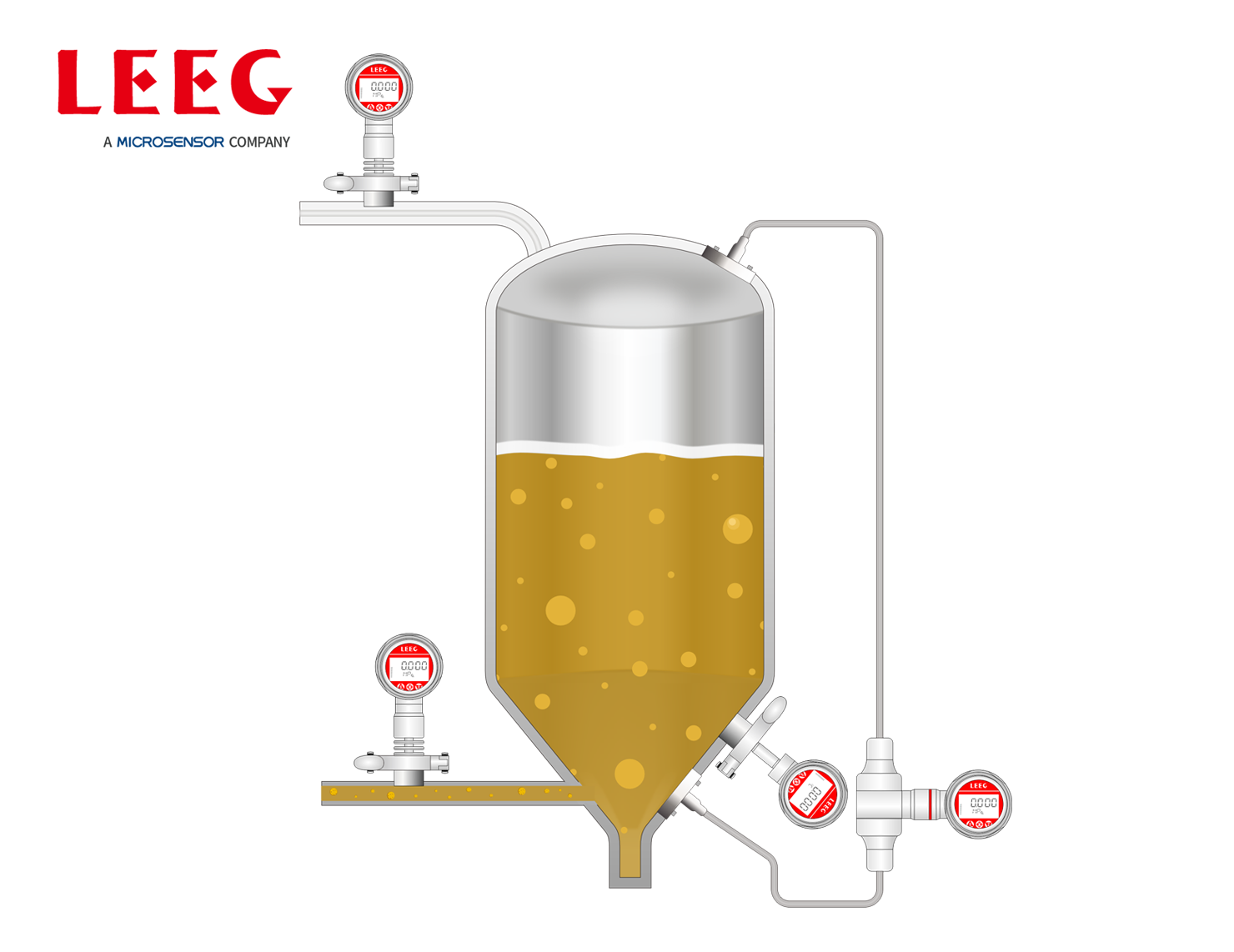

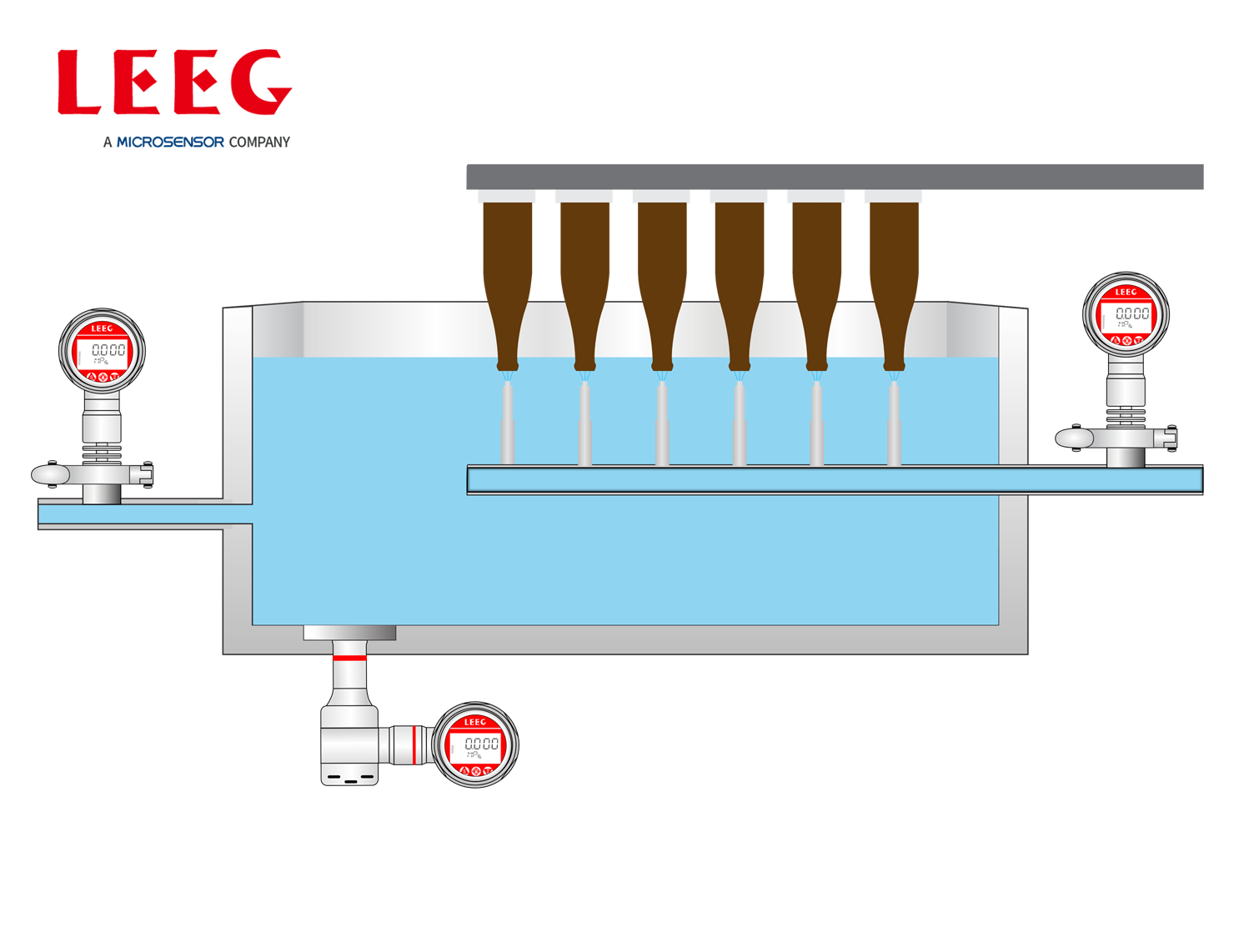

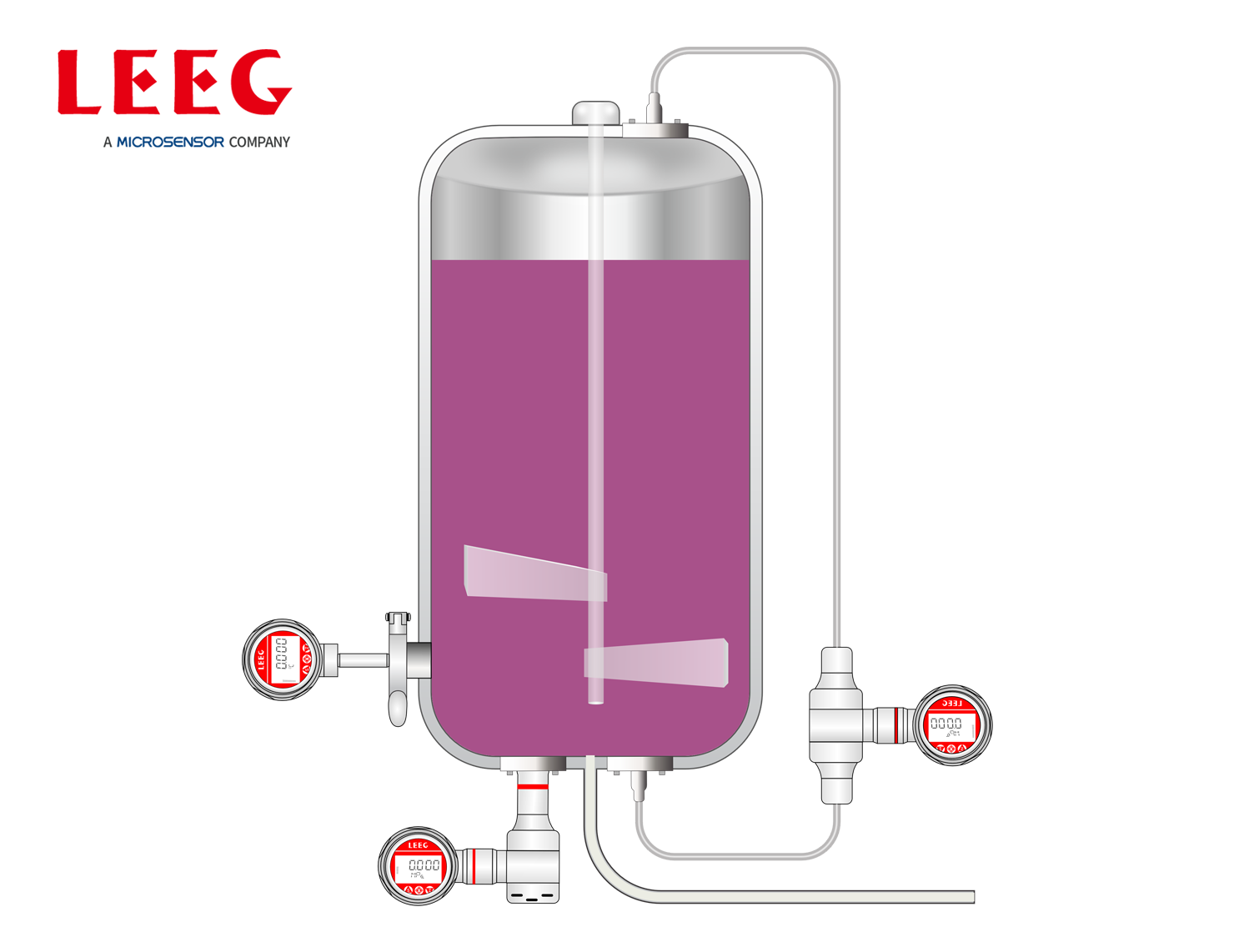

Application Introduction

When the malt juice cools to the appropriate temperature, adding yeast initiates the fermentation process. During this process, yeast converts maltose dissolved in the malt juice into carbon dioxide and alcohol. To ensure a smooth fermentation process, it is necessary to measure the temperature and liquid level of the fermentation tank, as well as the carbon dioxide in the recovery pipe and the pressure in the yeast pipe.

Contact Engineer

Copyright © 2026 MICRO SENSOR CO., LTD

Copyright © 2026 MICRO SENSOR CO., LTD