-

Products

- Solutions

- Service Support

Pages

- Pressure Sensor

- Pressure Transmitter and Transducer

- What is a Pressure Transducer?

- Level Transmitter and Sensors

- Differential Pressure Sensors

- Differential Pressure Transmitters

- Level transmitter for Fuel and Chemical

- Water Pressure Sensors

- Industrial Pressure Sensors and Transmitters

- Switches

- Liquid Pressure Sensors and Transmitters

- Company

-

Products

-

Solutions

-

Applications

-

News

-

Support

-

About Us

Products(9) | Download(13) | Applications(1) | News(1) | FAQ(0) | Blogs(0) | Solutions(2) |

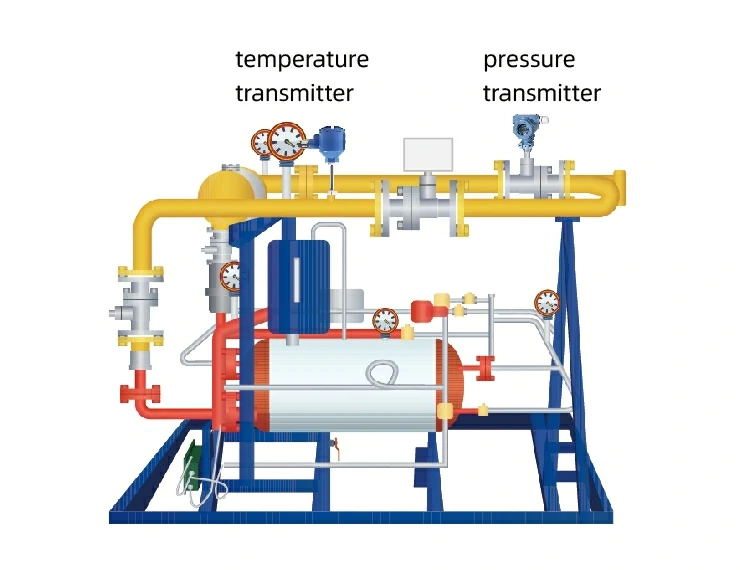

Gas Skid Equipment Pressure and Temperature Monitoring

Gas skid equipment is a critical component in gas distribution systems. Equipped pressure and temperature transmitters can monitor parameters in real time. Then, the data is transmitted remotely to a central control room. The engineer or operator detects abnormal situations in time. It ensures the normal operation of the equipment and system.

/Industries-details_Gas-Skid-Equipment-Pressure-and-Temperature-Monitoring.html | Details >

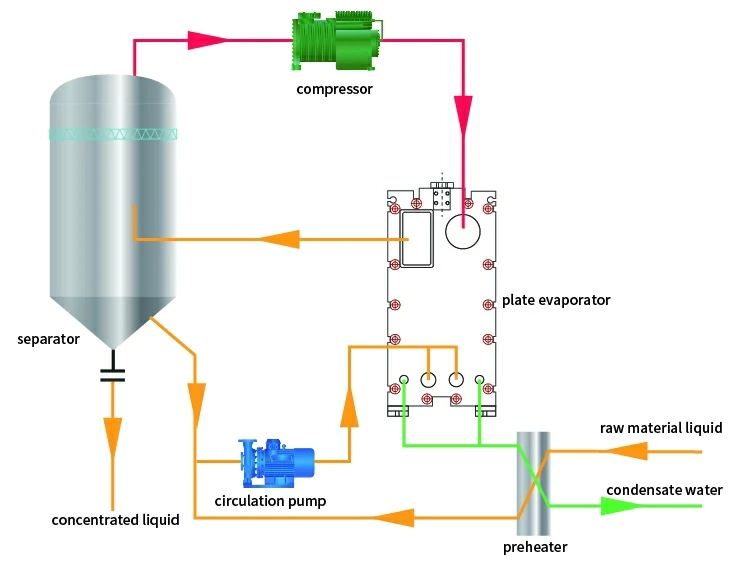

MVR Evaporation System Pressure, Temperature, and Flow Monitoring

The MVR evaporation equipment requires the use of intelligent pressure transmitters to monitor the liquid level in the separator for feed control. It also monitors the liquid level in the condensate tank, providing timely water replenishment for the condenser, allowing it to condense rapidly. Concurrently, the liquid level height of the raw material tank and the mother liquor tank is monitored. When the liquid level is depleted, raw liquid is added to maintain the normal progress of the process. Intelligent temperature transmitters are used to monitor the steam temperature in the heater, continuously heating the raw liquid for the separation of the solution and the solute. It also monitors the temperature of the separator cavity for efficient separation of the solute and solvent. Flowmeters are used to calculate the volume of the raw material liquid in the feed pump, accumulating the flow.

/Industries-details_MVR-Evaporation-System-Pressure-Temperature-and-Flow-Monitoring.html | Details >

Contact Us

MICRO SENSOR CO., LTD

Headquarters

No. 18, Yingda Road,

Baoji, 721006,Shaanxi,P.R.China

German Subsidiary

Micro Sensor GmbH

Girardetstr. 6, D-45131 Essen, Germany

Tel: +86-29-88346384

Whatsapp: 15114817352

Email: sales@microsensor.cn

- Pressure Sensors

- Pressure Transmitters

- Level Transmitters

- Temperature Transmitters

- Flowmeters

- Accessories

- General Industry

- Process Industry

- Downloads

- Applications

Copyright © 2024 MICRO SENSOR CO., LTD

Copyright © 2024 MICRO SENSOR CO., LTD