Application Introduction

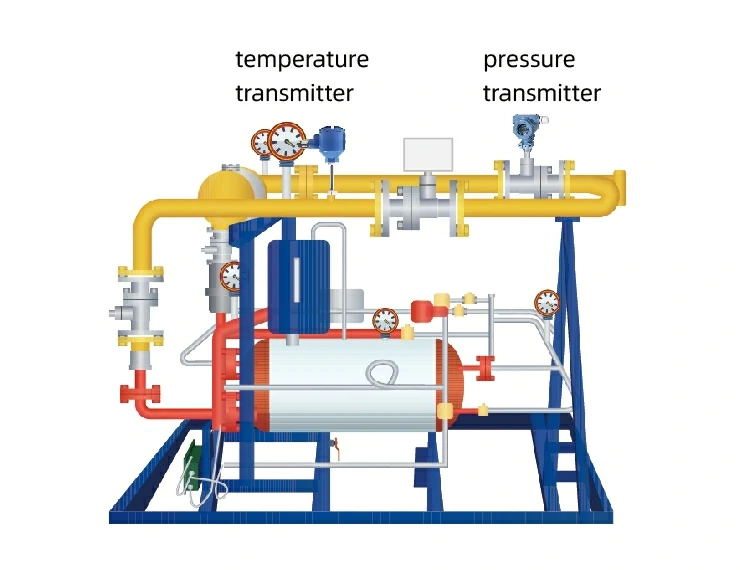

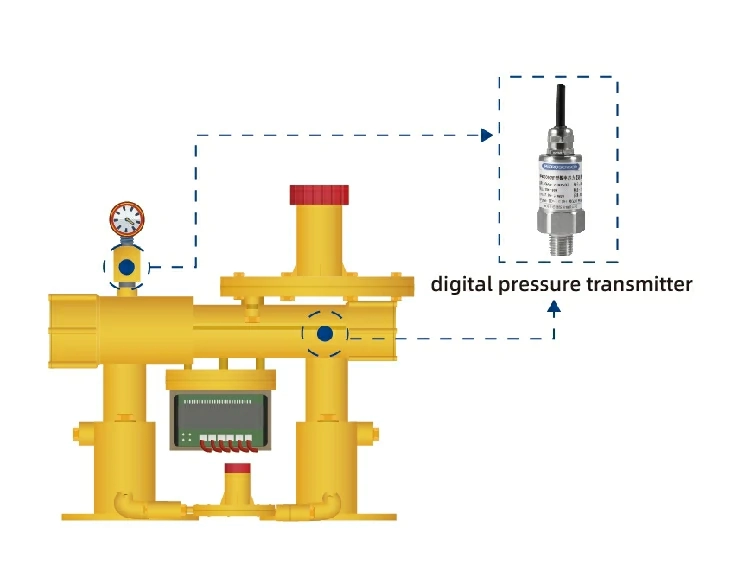

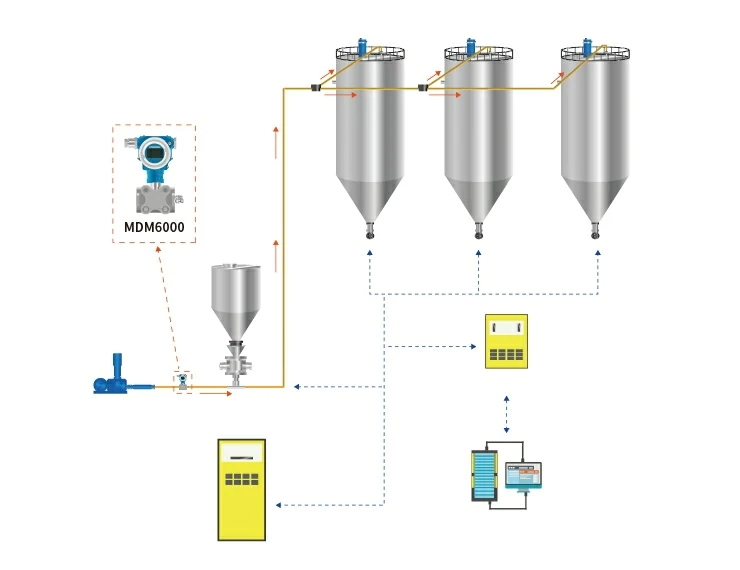

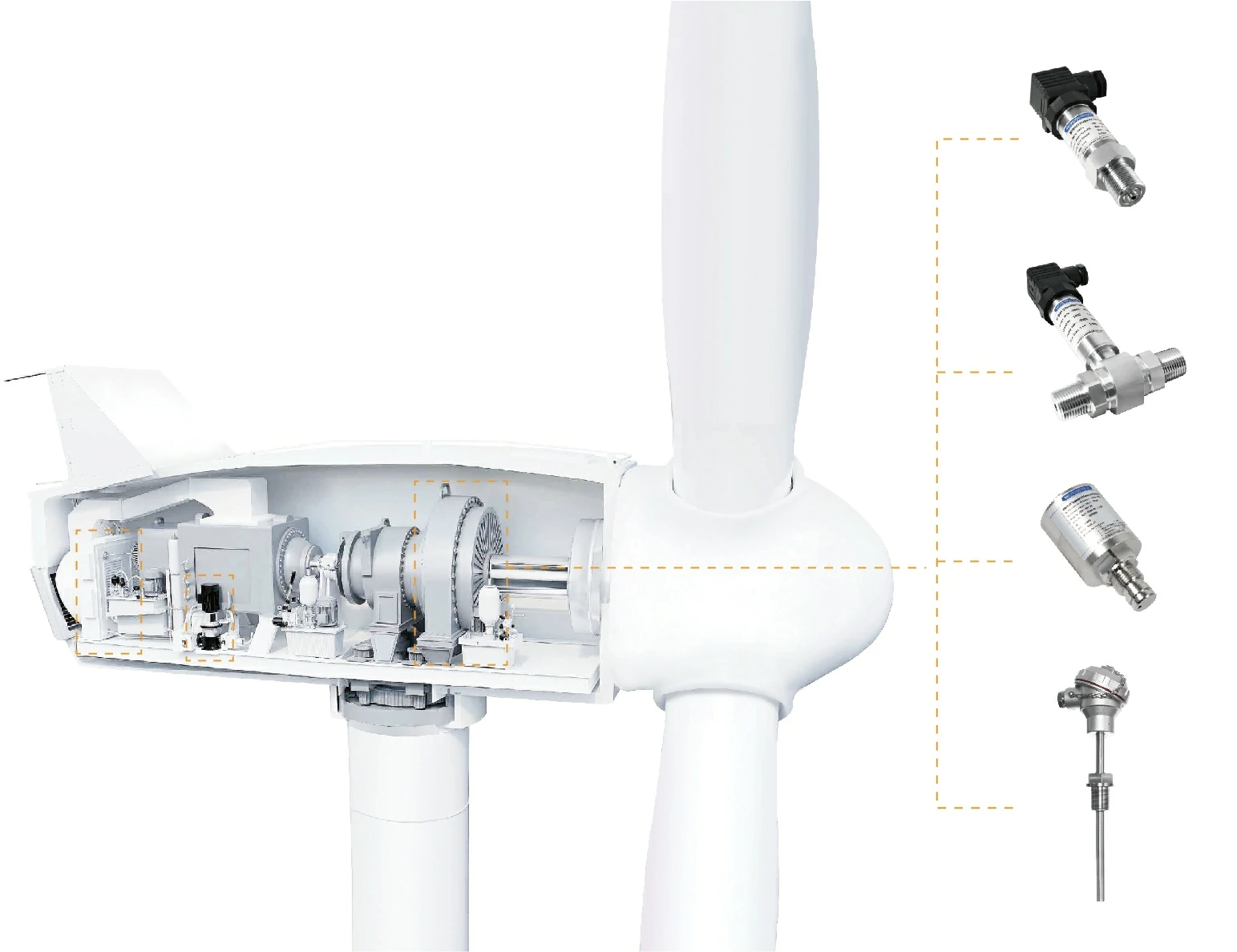

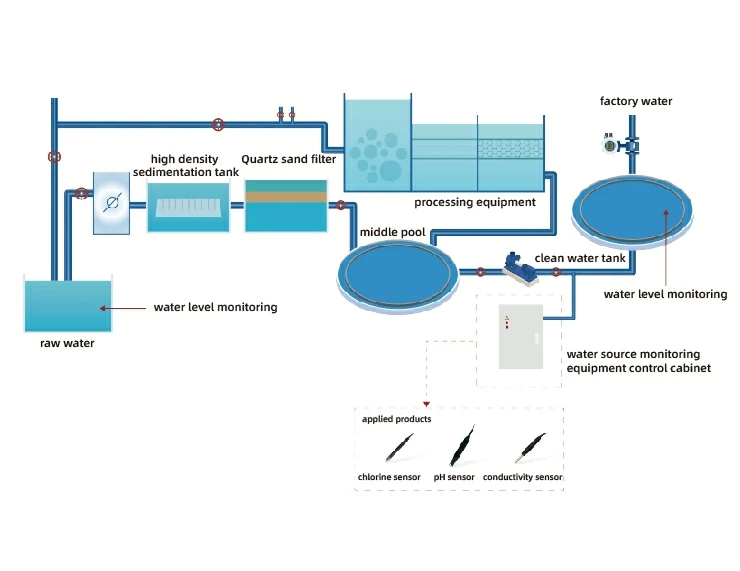

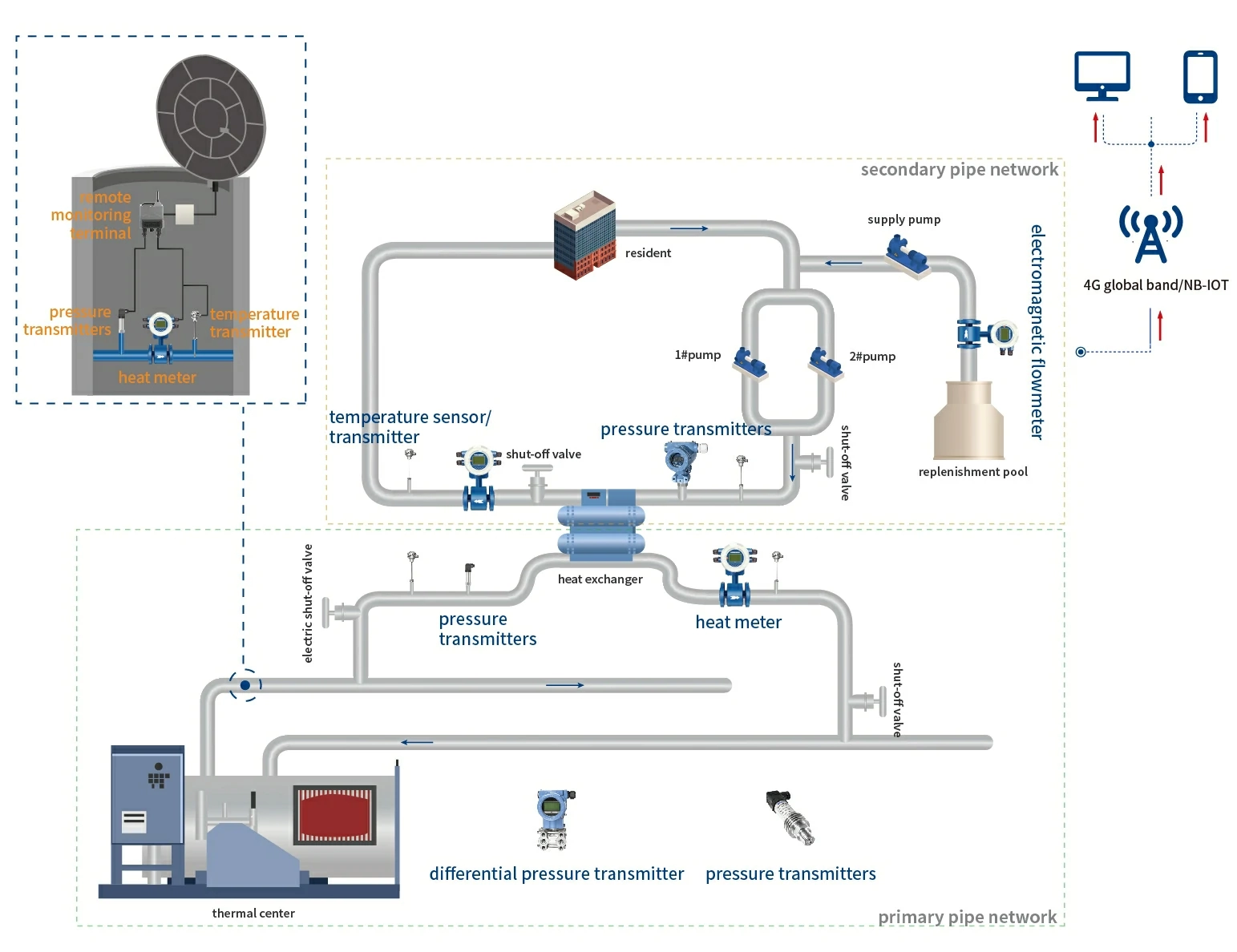

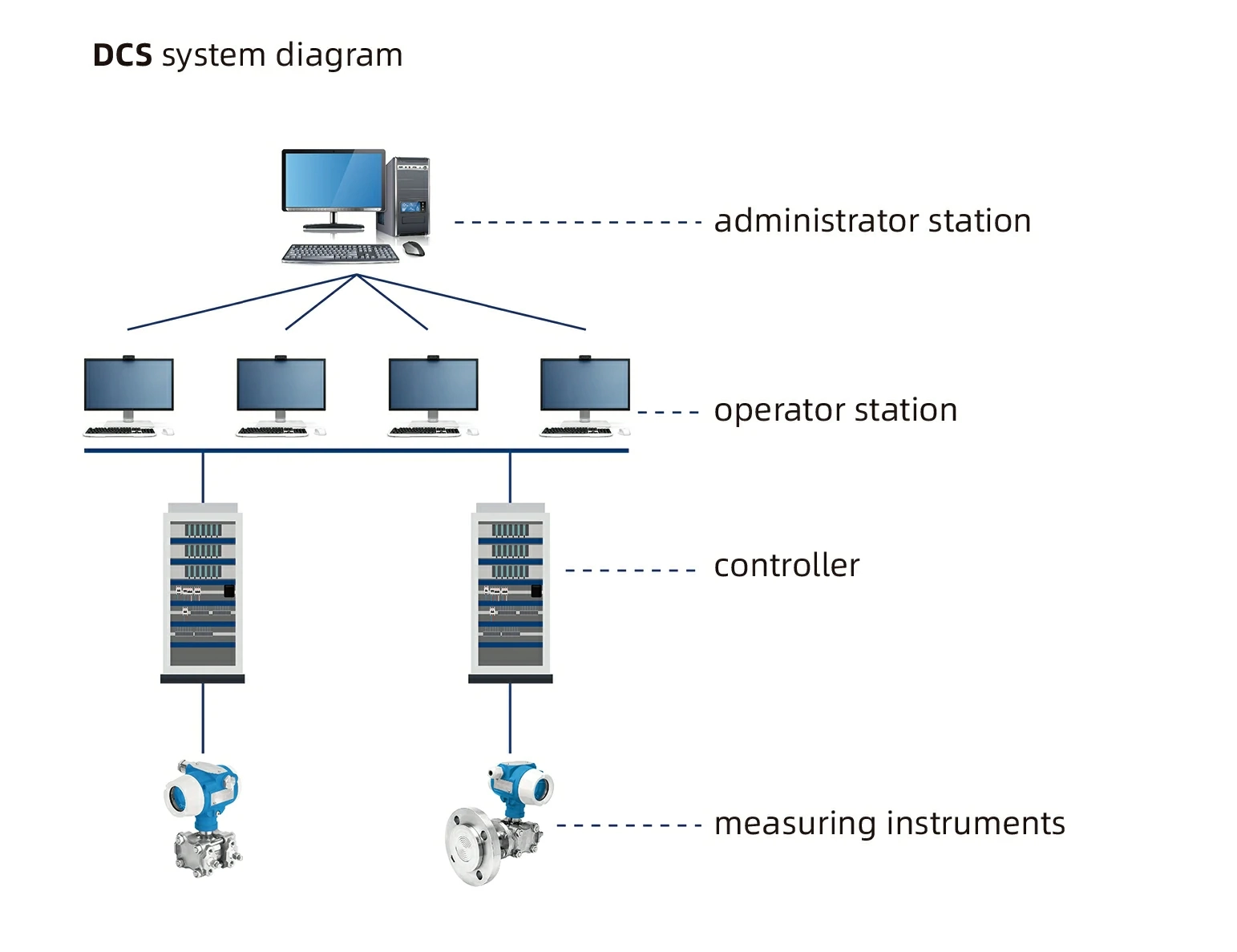

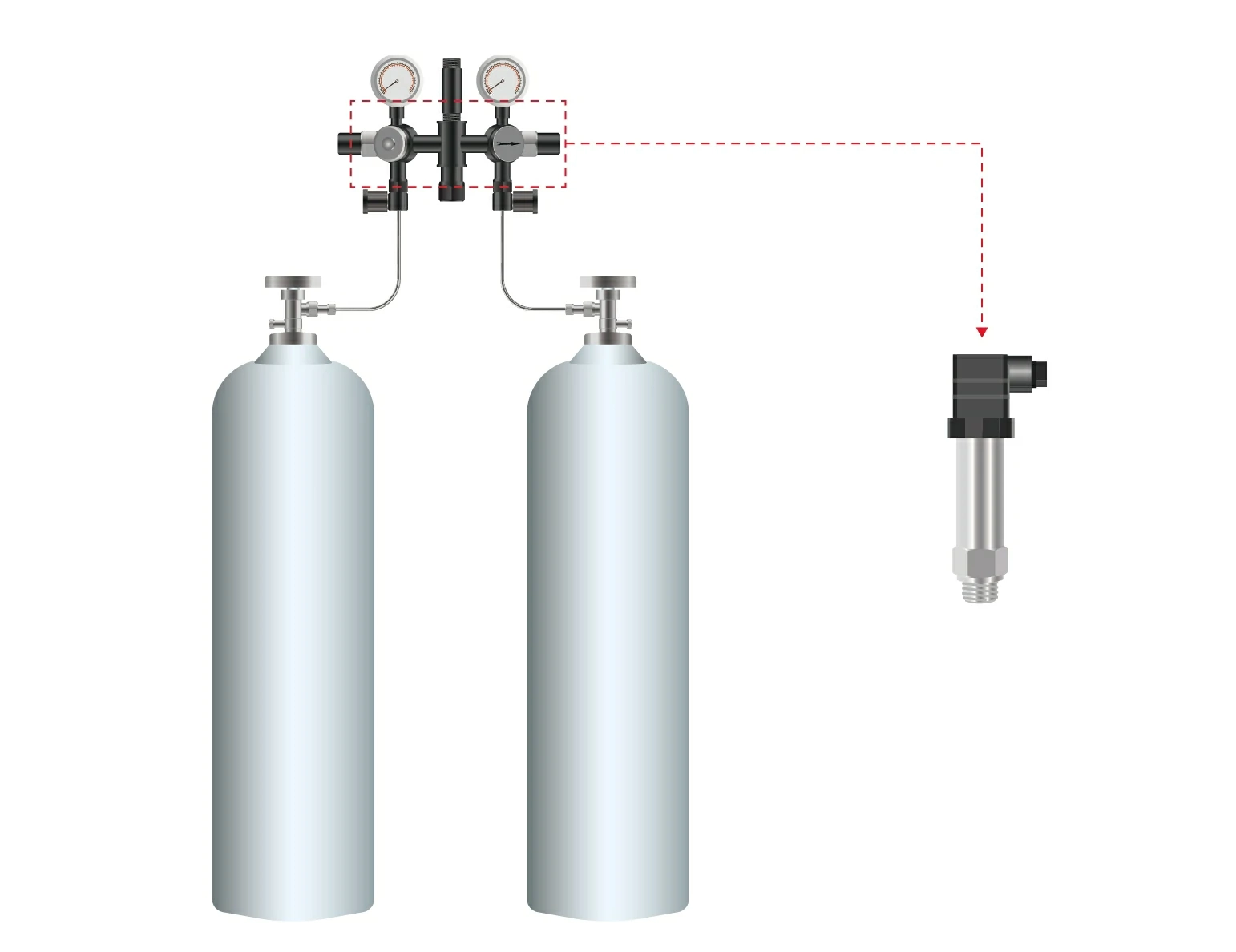

Electromagnetic flowmeters, ultrasonic flowmeters, level transmitters, pressure transmitters are installed in the heat exchange station heating system to obtain real-time data on pipeline flow, heat, temperature, and pressure, ensuring the normal operation of the heat exchange station.

Contact Engineer

Copyright © 2024 MICRO SENSOR CO., LTD

Copyright © 2024 MICRO SENSOR CO., LTD